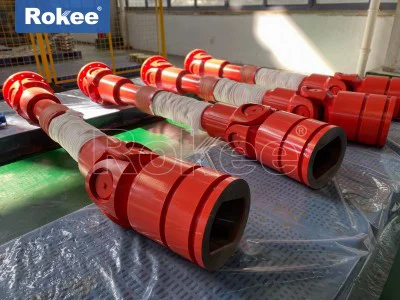

Universal Joint Coupling Of Water Pump

The universal joint coupling of a water pump is a mechanical device specifically designed to connect the water pump shaft with a drive shaft (such as a motor or engine shaft), which can efficiently transmit torque and rotational motion when the two axes are not completely aligned. Compared with ordinary couplings, universal joint couplings have greater angle compensation capabilities, can adapt to various complex installation conditions, and effectively reduce vibration and noise.

The universal joint coupling of a water pump usually consists of two universal joints, an intermediate shaft, and necessary connecting components. This structure enables flexible adjustment in multiple directions, compensating for axial, radial, and angular deviations, ensuring smooth and reliable power transmission.

The angular compensation capability is a significant feature of the universal joint coupling for water pumps, which can tolerate angular deviations of up to 15-45 degrees between the two shafts, greatly reducing the requirements for equipment installation accuracy and reducing installation and adjustment time. In terms of vibration absorption and noise reduction, high-quality universal joint couplings can effectively buffer and absorb vibrations and impacts from the drive end, protect water pump bearings and sealing systems, and extend equipment service life.

The common water pump universal joint couplings in the market are mainly divided into two categories: cross axis universal joints and ball cage universal joints. The cross axis universal joint has a simple structure and low cost, and is suitable for applications with low to medium speeds and torques; The ball cage universal joint can provide smoother transmission and higher speed capability, but the cost is relatively high.

The universal joint coupling of water pumps will continue to develop towards high performance, intelligence, and environmental protection, providing more reliable and efficient power transmission solutions for various fluid treatment systems.

-

Long Telescopic Cardan Shaft

-

SWP Universal Shafts

-

Scalable Cardan Shafts

-

Cardan Shaft Of Rolling Machine

-

Transmission Principle Of Universal Joint Coupling

-

Applicable Occasions For Cross Axis Universal Coupling

-

Advantages And Disadvantages Of Universal Joint Couplings

-

Internal Spline Universal Shaft Coupling