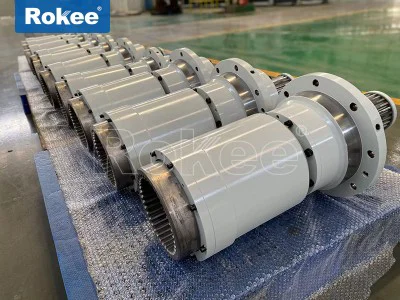

Brake Drum Gear Couplings

The brake drum gear coupling integrates brake function components on the basis of the standard drum gear coupling, forming a composite coupling device that combines transmission and braking functions. This special design gives it an irreplaceable advantage in situations where rapid braking is required, such as lifting and transportation, metallurgical steel rolling, etc.

The brake drum gear coupling integrates drum gear transmission technology and braking function, forming a series of significant technical advantages, making it an irreplaceable key transmission component in the heavy industry field. By analyzing its performance characteristics and technical parameters in depth, we can have a more comprehensive understanding of the engineering value of this type of coupling.

Core performance advantages

Excellent bearing capacity: Under the same external dimensions, the torque transmission capacity of the drum gear coupling is on average 15% -20% higher than that of the spur gear coupling. This characteristic originates from the optimized contact mechanism of the drum shaped tooth surface, which enables the load to be evenly distributed along the tooth width direction, avoiding the phenomenon of stress concentration at the end. Taking the G Ⅱ CLZ type coupling as an example, its nominal torque range can reach 0.4-4500kN · m, covering various application requirements from light to super heavy. In a practical engineering case, a certain metallurgical enterprise's 1800mm hot rolling production line replaced the traditional straight tooth coupling with a drum gear coupling, resulting in a significant reduction in equipment vibration value from 6.5mm/s to 2.1mm/s. The annual downtime maintenance time was reduced by 120 hours, and the annual single line efficiency was improved by more than 800000 yuan.

Excellent compensation capability: The drum gear coupling exhibits all-round displacement compensation performance, with angular compensation up to ± 1.5 ° or even higher (compared to the ± 1 ° of the straight tooth coupling), radial compensation capability typically ranging from 0.2% -0.3% of the coupling outer diameter, and axial compensation ranging from ± 1mm to ± 5mm. This multi-directional compensation characteristic enables it to effectively absorb equipment installation errors, foundation settlement, and thermal deformation during operation, protecting bearings and shaft systems from the influence of additional loads. Especially in heavy equipment, this compensation capability can significantly extend the service life of various components in the transmission system.

Integrated braking function: The brake drum gear coupling integrates transmission and braking functions, saving installation space and simplifying the transmission chain structure. The brake wheel surface of WGZ type coupling has undergone special hardening treatment, with stable friction coefficient and strong wear resistance, and can withstand frequent start stop working conditions. Actual testing has shown that a properly configured braking system can enable heavy equipment to achieve complete braking within 2-3 seconds in emergency situations, greatly improving operational safety. At the same time, integrated design reduces the alignment issues of traditional split brake systems and lowers maintenance complexity.

Efficient lubrication and thermal management: In response to the heat generated during the braking process, the high-end brake drum gear coupling adopts a forced thin oil lubrication system. The lubricating oil is used as both a tooth surface lubricant and a cooling medium for circulation. Test data shows that the wear of gear surfaces lubricated with thin oil is only about 10% of that lubricated with grease, and it can effectively remove braking heat and prevent material performance degradation. Some models also adopt optimized oil circuit design, using centrifugal force to accurately spray oil into the meshing area, ensuring reliable operation under high temperature conditions.

From the perspective of material and process, high-quality brake drum gear couplings adopt multi-layer composite heat treatment technology: the gear blank is first quenched and tempered to obtain core toughness (hardness HRC28-32), the gear surface is then carburized and quenched to achieve high hardness (HRC58-62), and finally stabilized to eliminate internal stress. This "hard on the outside and tough on the inside" structure ensures the wear resistance of the tooth surface and prevents the risk of brittle fracture. In terms of dynamic performance, the drum gear coupling that has undergone precise dynamic balancing can adapt to high-speed working conditions, with a maximum allowable speed of 4000r/min (depending on the specifications).

The correct selection of brake drum gear coupling is a key link to ensure the reliable operation of the transmission system. Reasonable selection can not only fully leverage the performance advantages of couplings, but also significantly extend the service life of equipment and reduce overall operating costs.

Core selection elements

Torque parameter calculation: The primary consideration for selection is the amount of torque that the coupling needs to transmit. When calculating, it is necessary to distinguish between steady-state torque and peak torque, especially for impact load situations, and it is recommended to take a safety factor of 2.5-3.0. The formula for calculating dynamic torque is: dynamic torque=theoretical torque x operating condition factor x safety factor. The operating condition coefficient needs to consider the type of driving source (such as electric motors, turbines, etc.) and the characteristics of the driven equipment (such as fans, compressors, etc.).

Compensation requirements for shaft displacement: Different equipment produces different shaft deviations during operation, and when selecting, it is necessary to evaluate the radial, axial, and angular displacement of the system. Generally speaking, drum toothed couplings can withstand angular deviations of ± 1.5 ° and axial deviations within 0.3mm. For special working conditions such as large rolling mills, significant axial displacement may occur due to roll adjustment, requiring the use of specially designed large compensation couplings, such as WGT type with intermediate sleeves or special drum shaped GII-CLZ type.

Braking performance requirements: The selection of braking type couplings requires additional consideration of parameters such as braking torque, braking frequency, and heat dissipation conditions. The WGZ type brake wheel coupling is suitable for medium braking frequencies (≤ 120 times per hour), while the WGP type brake disc design is more suitable for high-frequency braking or harsh environments that require liquid cooling for heat dissipation. The selection of brake surface diameter should ensure sufficient heat capacity to prevent performance degradation caused by overheating of the brake. Experience has shown that the surface temperature of brake discs/wheels should be controlled below 250 ℃, and if it exceeds this temperature, forced cooling measures should be considered.