Plum Couplings

Plum coupling is an elastic coupling widely used in mechanical transmission systems, named after its internal elastic body in the shape of plum blossom petals. This type of coupling achieves flexible connection between two shafts through an intermediate elastic element (usually made of polyurethane or rubber material), which can effectively compensate for axial, radial, and angular deviations, while also having shock absorption and buffering functions.

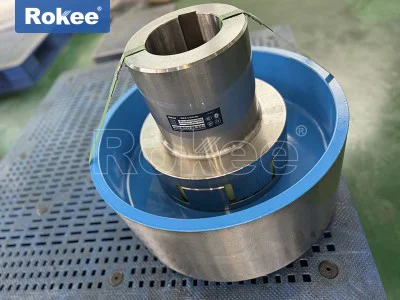

The plum coupling mainly consists of three core components:

Two metal coupling halves: typically made of aluminum alloy, steel, or stainless steel, with staggered claw teeth

Elastic plum blossom pad: located between two halves, shaped like a plum blossom petal, made of elastic materials such as polyurethane, natural rubber, or Hytrel

Fasteners: including bolts, nuts, etc., used to fix the connection between the coupling and the shaft end

Classified by elastic body shape

Standard plum coupling: symmetrical six or eight petal design, suitable for general working conditions

Curved Claw Type: The teeth are curved, providing a larger contact area and higher torque capacity

Claw shaped reinforced type: Special claw shaped design, suitable for high torque or impact load applications

Selection considerations

Torque requirement: Calculate the maximum working torque and peak torque of the system

Shaft diameter matching: Ensure that the coupling aperture matches the shaft diameter

Speed range: not exceeding the rated speed of the coupling

Environmental conditions: temperature, humidity, oil pollution, chemicals, etc

Deviation compensation requirement: Select the appropriate type based on installation accuracy requirements

Inertia matching: High speed applications need to consider rotational inertia

Main advantages

Excellent deviation compensation capability: simultaneously compensating for multiple deviations

Excellent shock absorption performance: can reduce vibration transmission by 30-50%

Backlash free transmission: maintaining precise synchronization

Compact structure: saves installation space

Easy maintenance: quick replacement of elastomers, no need to disassemble equipment

High cost-effectiveness: Compared to other types of couplings, it has outstanding cost-effectiveness

Application scenarios

Pump equipment: centrifugal pump, plunger pump, vacuum pump, etc

Fan system: industrial fan, cooling tower fan

Conveyor machinery: belt conveyor, chain conveyor

Machine tool industry: CNC machine tools, milling machines, lathes

Food packaging machinery: filling machine, labeling machine

Power generation equipment: small generators, wind power yaw systems

Automated production lines: robotic arms, assembly lines

As a fundamental component in the field of mechanical transmission, the technological development of plum couplings will continue to provide more reliable and efficient connection solutions for industrial equipment. Proper selection and use of plum couplings can significantly improve equipment operating efficiency, extend equipment lifespan, and reduce maintenance costs.