Jaw Type Flexible Couplings

Jaw type flexible coupling (also known as claw shaped elastic coupling or plum blossom coupling) is a widely used flexible connection device in mechanical transmission systems. It connects two shaft systems through elastic elements, which can transmit torque and compensate for radial, axial, and angular deviations between shaft systems, while also having the function of buffering and vibration reduction.

Jaw type flexible couplings play an important role in industrial production due to their simple structure, easy installation, and low maintenance costs. Compared with rigid couplings, flexible jaw couplings can effectively reduce the additional load caused by misalignment of the shaft system and extend the service life of the equipment; Compared with gear couplings, it has the advantages of low noise and no need for lubrication.

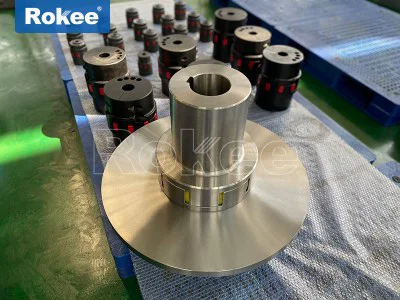

Jaw flexible couplings typically consist of three core components:

Two metal half couplings: usually forged or cast from high-quality alloy steel, with a precision machined surface, and each half coupling end face designed with several protruding "claws"

Elastic element (plum blossom pad): located between two half couplings, usually made of polyurethane, rubber or other polymer materials, shaped like a plum blossom petal

Connecting bolt assembly: used to secure two half couplings, some models may include protective covers

The "claws" of claw couplings are usually designed with 3-8 claws (commonly 6 claws), which are evenly distributed on the circumference to form a staggered meshing structure.

The cross-sectional shapes of claws are diverse, including:

Straight claw type: simple structure, easy to manufacture

Curved claw type: large contact area, high load-bearing capacity

Composite surface claw shape: more uniform stress distribution

The different materials of elastomers determine the performance differences of couplings:

Polyurethane elastomer: with a wide range of hardness, good wear resistance, and excellent oil resistance

Rubber elastomer: excellent shock absorption performance, but poor oil and high temperature resistance

Engineering plastic elastomer: such as nylon, suitable for special working conditions

Metal spring plate: used in high torque applications

Jaw couplings transmit torque through elastic bodies in a compressed state. When the driving shaft rotates, the claws of the half coupling push the elastic body, which then transmits the force to the claws of the driven half coupling. This design ensures smooth torque transmission and can absorb impact loads.

Deviation compensation principle

Radial deviation compensation: The deformation ability of the elastic body allows for a certain offset between the two axis centerlines

Angular deviation compensation: The relative tilt between the claw and the elastic body can adapt to the angular deviation of the two axes

Axial deviation compensation: The compression/tension characteristics of elastomers allow for axial displacement

Typical compensation capability range:

Radial deviation: 0.1-0.5mm

Angular deviation: 0.5 ° -1.5 °

Axial deviation: ± 0.5- ± 2mm

Jaw flex couplings have the following dynamic characteristics:

Nonlinear torsional stiffness: low stiffness during small deformations, increased stiffness during large deformations

Damping characteristics: The internal friction of the elastic body provides vibration damping

Critical speed influence: Mass distribution affects the critical speed of the system

Main advantages

Compact structure: Small in size, suitable for situations with limited space

Maintenance free: No lubrication required, reducing maintenance workload

Electrical insulation: Non metallic elastomers can provide insulation performance

Buffer damping: effectively reducing the vibration and noise of the transmission system

Good economy: lower cost than most other types of flexible couplings

Typical application scenarios

General mechanical equipment: pumps, fans, compressors, etc

Material conveying system: conveyors, lifting equipment

Power generation equipment: small generators, water turbines

Automation equipment: robots, CNC machine tools

Shipbuilding Industry: Auxiliary Transmission Systems

Especially suitable for the following working conditions:

Medium torque transmission demand

In situations where certain deviation compensation is required

Clean environment, without a large amount of abrasive particles

In situations where noise control is required

Jaw type flexible couplings play an important role in the field of medium torque transmission due to their excellent cost-effectiveness and reliable performance. When selecting, factors such as torque, speed, deviation compensation requirements, and environmental conditions should be comprehensively considered. For ordinary industrial applications, standard models usually meet the requirements; Under special working conditions, customized solutions may be considered.