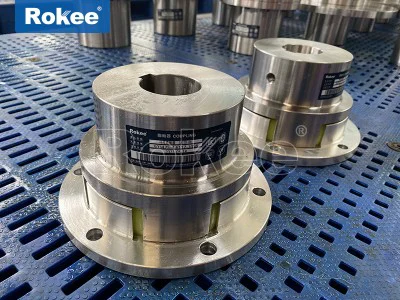

Flexible Jaw Shaft Couplings

Flexible jaw shaft coupling is a key connection device widely used in industrial machinery transmission systems. It achieves flexible connection between two shafts through a special "claw shaped" structure design, which can compensate for a certain degree of axial, radial, and angular deviation. This type of coupling is widely used in various mechanical equipment due to its compact structure, high torque transmission, and easy installation and maintenance.

Compared with traditional rigid couplings, flexible jaw shaft couplings have significant advantages. When there is misalignment in the transmission system, it can effectively absorb vibration and impact, protect the transmission shaft and bearings from damage, reduce energy loss, and improve transmission efficiency. Its unique flexibility characteristics make it play an irreplaceable role in modern high-precision, high-speed transmission systems.

A typical flexible jaw shaft coupling is mainly composed of the following parts:

Metal or nylon claw discs: used in pairs, usually made of high-strength alloy steel or engineering plastics

Elastic element: located between two claw disks, commonly made of materials including polyurethane, rubber, or special composite materials

Shaft sleeve or flange: used to connect with the drive shaft and the driven shaft

Fasteners: bolts, nuts, etc. used to fix various components

Flexible jaw shaft couplings transmit torque through interlocking claw structures and intermediate elastic elements. When the driving shaft rotates, it drives one side of the claw plate to rotate, and the power is transmitted to the other side of the claw plate through the elastic element, thereby driving the driven shaft to rotate. Elastic components can absorb and buffer additional loads caused by misalignment of the shaft system while transmitting torque, achieving flexible transmission.

Main features and advantages

Compensation capability

The flexible jaw shaft coupling has excellent deviation compensation capability:

Axial deviation: usually compensated for 0.5-3mm

Radial deviation: The compensation range is generally between 0.2-1.5mm

Angular deviation: Generally, a deviation of 0.5 ° -3 ° is allowed

This multi-directional compensation capability makes it particularly suitable for situations where installation accuracy is not high, greatly reducing the difficulty of mechanical assembly.Vibration reduction and noise reduction

The elastic element in the middle can effectively absorb and dampen vibrations, reducing the noise level of the transmission system, which is particularly important for high-precision equipment and environments with strict requirements.Maintenance free design

Most flexible jaw shaft couplings adopt a lubrication free design, reducing maintenance workload and costs, making them particularly suitable for equipment that is difficult to access or requires continuous operation.overload protection

When the system is overloaded, the elastic components may deform or break, thereby protecting more expensive transmission components from damage.

When choosing a flexible jaw shaft coupling, comprehensive consideration should be given to:

Transmission power and torque requirements

Shaft diameter size and connection method

Types and degrees of deviations present

Environmental conditions (temperature, humidity, corrosiveness, etc.)

Do you need electrical insulation characteristics

Correct installation steps

Check the size matching of the shaft and coupling

Clean the contact surface between the shaft and coupling

Install the half coupling onto the shaft using appropriate methods (hot or press fit)

Align the two axes and control the misalignment within the allowable range

Install elastic components and the other half of the coupling

Uniformly tighten all bolts to the specified torque

Common installation errors

Excessive deviation exceeds the coupling compensation capability

Using incorrect installation tools resulted in component damage

Uneven tightening torque of bolts

Ignore the requirement for axial clearance

Although flexible jaw shaft couplings are generally maintenance free, regular inspections are still necessary

Check if there are cracks, deformations, or wear on the elastic components

Confirm that all fasteners are not loose

Observe whether there are any abnormal vibrations or noise during operation

More frequent inspections are required in harsh environments

flexible jaw shaft couplings are widely used in:

Pump equipment: centrifugal pumps, vacuum pumps, etc

Fan system: industrial fan, cooling tower fan

Compression machinery: air compressor, refrigeration compressor

Conveyor equipment: conveyor belt, elevator

Processing machinery: machine tools, injection molding machines