Flexible Plum Blossom Couplings

Flexible plum blossom coupling is an elastic coupling widely used in mechanical transmission systems, named after its internal structure resembling plum blossom petals. This type of coupling achieves flexible connection between shafts by setting elastic elements (usually plum blossom shaped elastic bodies) between two half couplings, which can effectively compensate for axial, radial, and angular deviations.

Compared with traditional rigid couplings, flexible plum blossom couplings have significant shock absorption and buffering functions, which can absorb and reduce vibrations and impacts during transmission, protecting equipment from damage. Its compact structural design and simple installation make it an indispensable transmission component in modern industrial equipment.

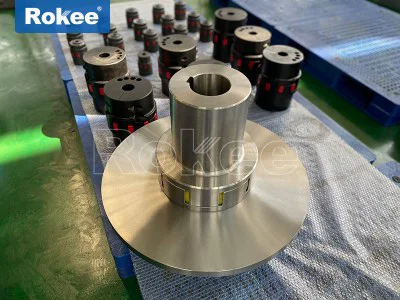

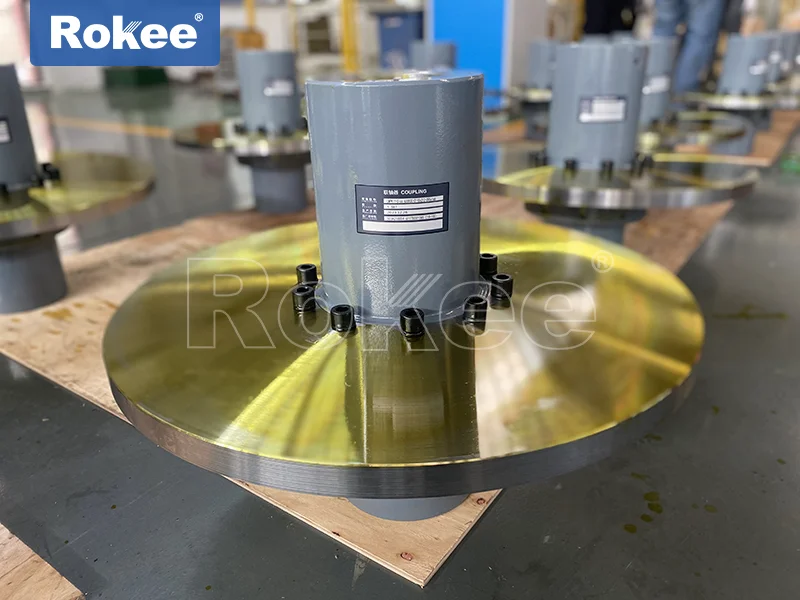

The flexible plum blossom coupling mainly consists of three parts:

Two metal half couplings: usually made of high-quality alloy steel or stainless steel materials, with precision machining to ensure dimensional accuracy. One end of the half coupling is connected to the drive shaft or driven shaft, and the other end is designed with a special flange structure for fixing the elastic element.

Plum shaped elastomer: This is the core component of the coupling, made of high-performance polyurethane, rubber, or other elastic materials. The petal shaped design of elastomers enables them to withstand deformation in multiple directions while providing the necessary torsional stiffness.

Fastener system: including bolts, nuts, washers, etc., used to ensure reliable connection between various components of the coupling. Some models are also equipped with safety shields to prevent foreign objects from entering and ensure safe operation.

The flexible plum blossom coupling exhibits multiple outstanding performances in industrial applications:

Excellent deviation compensation capability: It can simultaneously compensate for axial deviation (± 0.5-5mm), radial deviation (0.1-3mm), and angular deviation (± 1 ° -5 °), depending on the size and model of the coupling.

Excellent shock absorption performance: Elastic components can effectively absorb and dampen vibrations, reduce the noise level of the transmission system (usually by 5-15 decibels), and extend the service life of equipment.

Maintenance free design: Most plum blossom couplings adopt a fully enclosed structure, which does not require lubrication and reduces maintenance workload and usage costs.

High torque transmission efficiency: The use of modern high-performance elastic materials enables its torque transmission efficiency to reach over 98%, while also having good overload protection function.

Electrical insulation characteristics: Non metallic elastomers provide good electrical insulation performance, which can prevent damage to bearings caused by shaft currents.

Flexible plum blossom couplings are widely used in various industrial fields due to their excellent performance:

General mechanical equipment: Transmission connections for rotating machinery such as pumps, fans, compressors, and mixing equipment.

Automated production line: precision transmission applications such as CNC machine tools, robots, and conveyor systems.

Power generation equipment: Transmission systems for new energy equipment such as wind turbines and small water turbines.

Transportation: ship propulsion systems, rail transit auxiliary equipment, etc.

Special equipment: food processing machinery, pharmaceutical equipment, and other places that require high hygiene standards.

When selecting, engineers need to comprehensively consider factors such as torque requirements, speed range, environmental conditions (temperature, humidity, corrosiveness, etc.), and installation space limitations to ensure that the coupling can operate stably for a long time.

Proper installation and maintenance are key to ensuring the performance of flexible plum blossom couplings:

Installation steps:

Check if the dimensions of the shaft end and keyway meet the requirements of the coupling

Clean the shaft end and coupling inner hole, remove burrs and dirt

Gently push the half coupling onto the shaft, avoiding direct hammering with a hammer

Use specialized tools to press the coupling into place

Install elastic components to ensure that each "petal" is evenly stressed

Gradually tighten the connecting bolts in diagonal order to the specified torqueMaintenance points:

Regularly inspect the elastic components for cracks, hardening, or excessive wear

Observe whether there is any abnormal vibration or noise during the operation of the coupling

Check all fasteners for looseness

When used in harsh environments, shorten the inspection cycle appropriatelyCommon faults and solutions:

Premature wear of elastomers: check if the alignment accuracy exceeds the tolerance or if there is an overload situation

Abnormal vibration: recheck the dynamic balance and alignment situation

Coupling overheating: Check for interference, friction, or lubrication issues

Flexible plum blossom couplings will achieve more breakthroughs in intelligent diagnosis, adaptive compensation, and provide more reliable connection solutions for modern industrial transmission systems.