Tooth Couplings

As a core component in mechanical transmission systems, tooth couplings play an indispensable role in modern industrial equipment. This type of coupling, through a precise gear meshing structure, can not only efficiently transmit torque and rotational motion, but also effectively compensate for various deviations between shaft systems, thereby ensuring the smooth operation of the transmission system.

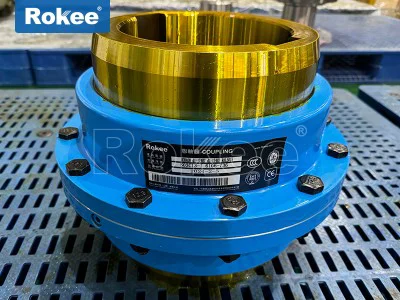

Tooth coupling is a mechanical transmission device that achieves power transmission through gear meshing. As a type of movable rigid coupling, it mainly consists of two core components: an inner gear ring and an outer gear shaft sleeve. It uses the mutual meshing of the inner and outer teeth to connect two concentric shafts and transmit torque. This type of coupling has the ability to compensate for the relative displacement of two shafts while transmitting power, making it an ideal choice for many industrial applications.

Structurally, the basic components of a toothed coupling include an inner ring gear, a flanged half coupling with outer teeth, and end caps. According to design requirements, small tooth couplings often adopt an integrated structure of end caps and inner gear rings, which simplifies the assembly process and improves the compactness of the overall structure. This sophisticated structural design enables the toothed coupling to achieve maximum transmission efficiency within a limited space, with relatively small radial dimensions yet capable of bearing significant torque loads.

The working principle of tooth coupling is based on the basic mechanism of gear meshing. When the driving shaft rotates, the meshing inner gear ring is driven by the outer gear shaft sleeve to rotate, thereby transmitting power to the driven shaft. During the transmission process, if there is a certain relative displacement between the two shafts (including radial, axial, or angular deviations), the inner and outer tooth surfaces can adapt to these deviations through relative sliding, thereby ensuring the continuity and stability of the transmission. It is worth noting that although this relative sliding solves the problem of deviation compensation, it also brings challenges of tooth surface wear and power loss. Therefore, a good lubrication and sealing system is crucial for the long-term stable operation of the toothed coupling.

From the perspective of performance characteristics, tooth couplings have several significant advantages: firstly, they have a compact structure, and their ability to transmit torque is often superior to other types of couplings under the same outer diameter size; Secondly, it has a high load-bearing capacity and is particularly suitable for low-speed and heavy-duty working conditions; Furthermore, it has a wide speed range, with ordinary models suitable for conventional speeds, while tooth couplings that have undergone high-precision dynamic balancing processing can even be used in high-speed transmission scenarios such as gas turbines. In addition, the coupling designed with drum shaped teeth also has a large angular compensation capability, which can adapt to more complex shaft deviation situations.

In terms of industrial applications, tooth couplings cover almost all heavy industry fields. Toothed couplings can be seen in steel rolling equipment in the metallurgical industry, crushers and ball mills in mining machinery, winches and walking mechanisms in lifting and transportation equipment, and large equipment in petrochemical, shipbuilding, water conservancy and other industries. Its reliability and adaptability make it the preferred connecting component in heavy-duty transmission systems, providing a solid foundation for the stable operation of modern industrial machinery.

Gear couplings can be divided into various types based on their structural characteristics and design concepts, each with its unique advantages and application scenarios. Understanding these different types of tooth couplings is crucial for selecting and using couplings correctly. In practical applications, engineers need to choose the most suitable coupling type based on the specific requirements of the transmission system, such as torque size, speed range, deviation compensation requirements, and working environment.

Drum gear coupling is currently the most widely used type of tooth coupling. Its biggest feature is that the tooth tips of the outer gear shaft sleeve are machined into a circular arc shape, and the entire gear blank is designed as a spherical surface. This drum shaped tooth structure brings multiple performance advantages: firstly, the compensation capability is significantly improved, allowing for a maximum angular displacement of 1.5 ° (50% higher than that of straight tooth couplings), and it can also better adapt to radial and axial deviations; Secondly, the improvement of contact conditions is achieved. The drum shaped tooth surface expands the contact area between the inner and outer teeth, avoiding the problem of stress concentration at the edge of the tooth end under angular displacement conditions in straight tooth couplings, thereby improving transmission stability and component life; Furthermore, the load-bearing capacity has been improved. Under the same structural dimensions, the torque transmission capacity of the drum toothed coupling is on average 15% -20% higher than that of the straight toothed coupling. Typical drum shaped tooth couplings include GIICL, GCLD and other series, among which GIICL type is further divided into Type I and Type II. Type I adopts a separated sealing end, allowing for larger radial displacement, while Type II is an integral sealing end with a more compact structure. The nominal torque range of these couplings is wide, ranging from 0.4kN · m to 4500kN · m, which can meet various transmission needs from ordinary machinery to heavy equipment.

The spur gear coupling is the basic form of a toothed coupling, in which the axial tooth blank of the outer gear sleeve is machined into a straight shape, and the indexing circle and root circle are both straight lines. The meshing form is exactly the same as that of the inner and outer teeth of a regular involute cylindrical gear. This type of coupling achieves limited compensation capability by increasing the backlash between the inner and outer teeth, but the compensation amount is relatively small, generally allowing only about 1 ° angular displacement. With the popularization of drum tooth technology, spur tooth couplings have gradually been regarded as obsolete products due to their limitations in compensation performance and load-bearing capacity, and are generally not recommended for use in new construction projects. However, in some situations with low requirements or strict space limitations, spur tooth couplings still have certain application space due to their simple structure and low cost.

The elastic pin gear coupling represents the combination design of toothed coupling and elastic coupling, and belongs to a type of flexible coupling with elastic elements. This type of coupling consists of two half couplings with semi-circular grooves, an outer ring, and nylon pins, which transmit torque through the pins instead of direct gear engagement. Its biggest feature is the use of nylon column pins instead of traditional metal tooth structures. One end of the column pin is made into a drum shape to increase compensation, and fixed retaining rings are installed at both ends to prevent slipping. The elastic pin tooth coupling has the ability to compensate for axial, radial, and angular axis offsets, and has a simple structure, good processability, no need for lubrication and maintenance, and operates smoothly, reliably, and noiselessly. According to different structures, it can be divided into LZ type (basic type), LZD type (tapered shaft hole), LZJ type (connecting intermediate shaft), and LZZ type (with brake wheel) series. However, due to the temperature sensitivity of nylon material (temperature resistance range is generally -20 ℃~70 ℃) and low damping coefficient, the vibration reduction performance of this type of coupling is weak and not suitable for situations that require strict control of vibration and noise.

Special application type tooth coupling is a specialized product developed for specific working conditions. The CLZ type tooth coupling is designed specifically for large-diameter pipe mills and metallurgical equipment, with excellent impact bearing performance. It includes 19 specifications and models from CLZ1 to CLZ19, covering a nominal torque range of 103780N · m to 1000000N · m. The GCLD type is a drum shaped tooth coupling specially designed for motor shaft extension, using GIICL basic gear meshing parameters. It has the characteristics of small tooth spacing, compact structure, and low moment of inertia, allowing for forward and reverse rotation and transmitting nominal torque range of 1120-50000N · m. The DY series tooth coupling is known for its unique closed design and specially hardened tooth surface, which can prevent dust from entering and lubricating oil leakage. It is suitable for high load and high-speed rotation scenarios under harsh working conditions. Although these specialized couplings have limitations in universality, they perform well in their respective target application areas and provide reliable solutions for solving special transmission problems.

Tooth couplings play an important role in the field of mechanical transmission, mainly due to their excellent performance characteristics and significant technological advantages. Compared with other types of couplings, toothed couplings perform outstandingly in terms of load-bearing capacity, deviation compensation, and transmission efficiency, making them an ideal choice for heavy-duty, high-speed, or precision transmission systems. A deep understanding of these performance characteristics can help engineers fully unleash the potential of toothed couplings in equipment design and maintenance.

Excellent load-bearing capacity is one of the most prominent features of toothed couplings. Due to the design of multiple teeth meshing simultaneously, the load is evenly distributed on multiple tooth surfaces, greatly improving the ability of torque transmission. Under the same outer diameter size, the load-bearing capacity of the drum toothed coupling is increased by an average of 15% -30% compared to the straight toothed coupling. This advantage is particularly valuable in applications with limited space but high torque requirements. For example, in the steel rolling equipment of the metallurgical industry, the nominal torque of the GIICL drum tooth coupling can reach 4500kN · m, which can meet the most demanding heavy-duty requirements. This high load-bearing capacity originates from the optimized design of the drum shaped teeth: the spherical tooth shape expands the contact area, making the load distribution more uniform and avoiding the stress concentration phenomenon at the tooth end of traditional straight tooth couplings. At the same time, the tooth surface that has undergone precision machining and hardening treatment has extremely high wear resistance, which can maintain good meshing even under long-term heavy load operation, extending the service life of the coupling.

Excellent deviation compensation capability is another major technical advantage of toothed couplings. In practical mechanical systems, due to manufacturing errors, installation deviations, thermal deformation during operation, or foundation settlement, various forms of relative displacement between connected shafts are inevitable, including radial displacement, axial displacement, and angular deflection. tooth couplings, especially drum shaped gear designs, can effectively compensate for these deviations and ensure the smooth operation of the transmission system. Specifically, the drum shaped tooth coupling allows for an angular displacement of up to 1.5 °, which is 50% higher than that of the spur tooth coupling; At the same time, it can also compensate for parallel offset of 0.01-0.02 inches. This compensation capability originates from the special geometric shape of the drum shaped teeth and the large tooth flank clearance. When there is a deviation in the shaft system, the inner and outer tooth surfaces can adapt through relative sliding without generating excessive additional loads. For example, in the transmission system of a large mining ball mill, due to the large size of the equipment, it is inevitable that there will be axis misalignment during installation and operation. After using the GCLZ drum shaped tooth coupling, the system can automatically compensate for these deviations, significantly reducing vibration and noise, and extending the service life of components such as bearings and seals.

The efficient transmission performance makes the toothed coupling perform excellently in energy transfer. The optimized design of the tooth coupling has a transmission efficiency of up to 99.7%, which means that only a very small portion of the input power is lost during transmission. Efficient transmission not only saves energy, but also reduces heat generation caused by power loss, which helps maintain stable operation of the system. This characteristic makes the toothed coupling particularly suitable for high-power transmission applications, such as auxiliary systems in power plants, ship propulsion systems, etc. The realization of high transmission efficiency mainly benefits from several aspects: precision machined tooth surfaces ensure good meshing quality; The optimized tooth profile curve reduces sliding friction; An effective lubrication system reduces the friction coefficient between tooth surfaces. It is worth noting that although there is relative sliding between the inner and outer tooth surfaces of the toothed coupling during operation, which may result in certain power losses, these losses can be controlled at a very low level by using appropriate lubricants and maintaining good sealing conditions.

The wide application adaptability demonstrates the multifunctionality of the toothed coupling. From low-speed heavy-duty metallurgical rolling mills to high-speed precision gas turbines, from dry and clean indoor environments to humid and dusty open-pit mining areas, tooth couplings can adapt to various harsh conditions through different designs and material choices. In low-speed and heavy-duty situations, such as the walking mechanism of lifting and transportation equipment, the design of couplings focuses on load-bearing capacity and impact resistance, using large modulus gears and sturdy structures; In high-speed applications such as steam turbine generator sets, emphasis is placed on high-precision dynamic balancing and vibration reduction design, with speeds up to 4000r/min or even higher. In addition, for special environmental requirements such as explosion-proof environments in the petrochemical industry or corrosion resistance requirements in marine engineering, tooth couplings can be made of stainless steel material or have special sealing designs.

These performance characteristics of tooth couplings do not exist in isolation, they are interrelated and influence each other, together constituting the technical advantages of tooth couplings. In practical engineering applications, it is necessary to weigh various indicators and select the most suitable type and specification of coupling based on specific working conditions and performance requirements. For example, in the transmission system of a steel continuous casting machine, it is necessary to consider both high torque requirements and adapt to shaft system deviations caused by thermal deformation. Generally, large-sized drum shaped tooth couplings are selected and equipped with high-pressure automatic lubrication systems to meet the requirements of bearing capacity, deviation compensation, and long-term reliable operation at the same time. It is precisely this comprehensive performance advantage that maintains the irreplaceable position of tooth couplings in the field of mechanical transmission.