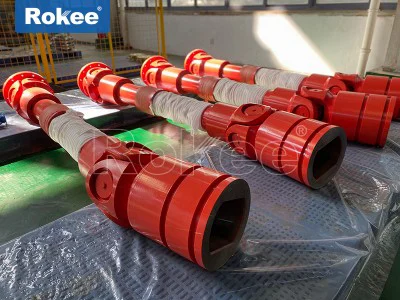

Industrial Cardan Shafts

As a key component in mechanical transmission systems, industrial cardan shafts play an indispensable role in modern industrial production. It achieves efficient transmission of power at different angles through unique structural design, solving the problem of angle deviation that traditional rigid connections cannot cope with.

A industrial cardan shaft is a mechanical device that can maintain power transmission even when there is an angle between two axes. Its core function is to solve the problem of angle deviation between rotating shafts. When two rotating shafts are not on the same straight line, ordinary couplings cannot effectively transmit power, while universal shafts allow the shaft to deflect within a certain angle through a special hinge structure, while maintaining stable torque transmission.

From a physics perspective, the working principle of a industrial cardan shaft is based on the theory of spatial linkage mechanisms. When the driving shaft rotates, the rotational motion and torque are transmitted to the driven shaft through the motion conversion of intermediate mechanisms such as cross shafts or ball cages. Although this conversion may cause speed fluctuations in a single joint industrial cardan shaft, the reasonable arrangement of dual joint industrial cardan shafts can eliminate this inequality and achieve synchronous transmission.

The efficiency of universal transmission systems typically ranges from 98% to 99.5%, thanks to advances in modern materials and manufacturing processes. The high transmission efficiency gives industrial cardan shafts significant advantages in energy sensitive applications such as wind power generation and electric vehicles. Meanwhile, its compact structure also highlights its unique value in space constrained environments such as automotive chassis and industrial robot joints.

industrial cardan shafts can be classified into various types based on their structure and usage, each with its unique advantages and application scenarios.

The cross axis industrial cardan shaft consists of two Y-shaped forks and a cross axis, which can rotate flexibly through needle roller bearings on the cross axis. This structure is simple, reliable, and has strong load-bearing capacity, making it particularly suitable for heavy machinery and construction vehicles. Typical applications include metallurgical rolling mills, mining machinery, and large-scale engineering equipment. The allowable axis deflection angle of a cross axis industrial cardan shaft is usually 15 ° -25 °, with a maximum of 45 °, and the torque transmission capacity ranges from a few Newton meters to several million Newton meters. Its disadvantage is that there will be speed fluctuations when using a single section, and it needs to be used in pairs and arranged correctly to ensure transmission synchronization.

The ball cage universal shaft adopts a spherical raceway and cage structure, with precision steel balls transmitting torque between the inner and outer raceways inside. Compared to the cross axis type, the ball cage industrial cardan shaft operates more smoothly, with less vibration and noise, and allows for a working angle of up to 25 ° -30 °, making it particularly suitable for high-speed situations. The front wheel drive system of automobiles commonly uses ball cage industrial cardan shafts, which can reach speeds of 3000-5000rpm or even higher. Modern cage type universal shafts adopt equal tooth design and precision grinding processing technology, which makes the load distribution more uniform and significantly improves the service life. The disadvantage is that the manufacturing cost is high, it is sensitive to foreign objects, and requires good sealing protection.

The ball fork industrial cardan shaft structure is between the cross shaft and the cage type, and power transmission is achieved through the spherical fork head and the force transmitting steel ball. This design is more compact than the cross axis type and simpler and more economical than the ball cage type. It is commonly used in applications with medium to low speeds and light loads, such as agricultural machinery and commercial vehicles. The allowable deflection angle of a ball fork industrial cardan shaft is generally around 20 °, which has good sealing performance and is suitable for harsh working environments.

Other special types include trident industrial cardan shaft (suitable for large angle deflection), diaphragm industrial cardan shaft (seamless transmission, suitable for precision machinery), elastic industrial cardan shaft (with rubber components, capable of absorbing vibration and impact), etc. In recent years, magnetic universal couplings have also emerged, which transmit torque through non-contact magnetic coupling without wear and are suitable for high cleanliness or vacuum environments.

The performance and lifespan of industrial cardan shafts largely depend on the selection of materials and manufacturing processes. Different components require differentiated material solutions based on their functional characteristics and stress conditions.

As the core load-bearing component of the cross axis industrial cardan shaft, the cross axis is usually made of high-quality alloy structural steel such as 20CrMnTi and 20CrMo. After carburizing and quenching treatment, the surface hardness can reach HRC58-62, while the core maintains the toughness of HRC30-35, ensuring both wear resistance and ability to withstand impact loads. The depth of the carburized layer is generally 0.8-1.4mm, and the surface roughness is controlled below Ra0.4 after precision grinding. In recent years, cross shafts prepared by powder metallurgy technology have been applied, resulting in more uniform material density and strength, and an increase in fatigue life of over 30%.

The bearing components are crucial to the performance of the industrial cardan shaft. Needle roller bearings are usually made of GCr15 bearing steel, with a hardness of HRC61-65 after heat treatment, and the working surface is ultra precision machined. Retainers are often made of copper alloys or engineering plastics (such as polyamide) to reduce friction and wear. High end applications are starting to use ceramic needle rollers, which, although costly, can extend their service life by 3-5 times, making them particularly suitable for situations with harsh lubrication conditions.

The fork head, flange and other structural components of the industrial cardan shaft are generally made of medium carbon alloy steels such as 42CrMo and 35CrMo, which have good comprehensive mechanical properties after quenching and tempering treatment. For fields with strong demand for lightweighting, such as aerospace and new energy vehicles, high-strength aluminum or titanium alloys are being adopted, which can reduce weight by 30% -50% while ensuring strength.

The sealing material has a decisive impact on the maintenance cycle of the industrial cardan shaft. The working temperature range of traditional nitrile rubber seals is generally -40 ℃ to+100 ℃, while the new fluororubber (FKM) seals can withstand environments from -30 ℃ to+200 ℃ and have better chemical corrosion resistance. The PTFE composite lip design further reduces frictional resistance and extends sealing life.

Modern industrial cardan shaft manufacturing integrates multiple precision machining technologies. The machining of the cross axis is carried out using CNC lathes and specialized grinders to ensure the dimensional accuracy and form tolerance of the shaft neck (roundness ≤ 0.003mm). The machining of fork heads involves five axis linkage milling centers to ensure the positional accuracy of bearing seat holes. The heat treatment process adopts a computer-controlled controlled controlled controlled atmosphere carburizing furnace, which precisely adjusts the carbon potential and temperature curve to avoid oxidation and decarburization.

Surface strengthening techniques such as rolling and shot peening are widely used in key parts of industrial cardan shafts, which can form residual compressive stress layers on the surface and increase fatigue strength by 30% -50%. New technologies such as laser surface quenching and plasma nitriding have also begun to be applied in high-end products, further extending their service life.

The assembly process adopts torque control tightening technology to ensure precise and consistent pre tightening force of the bearings. Dynamic balance testing is essential for high-speed industrial cardan shafts, usually requiring a balance level of G6.3 or higher, and some precision applications even require G2.5. Before leaving the factory, a bench test is required to simulate actual working conditions and verify performance indicators.

industrial cardan shafts play a crucial role in many industrial fields due to their unique angle compensation capability and efficient torque transmission characteristics. Different industries choose the appropriate type and configuration of industrial cardan shaft based on their working conditions and performance requirements.

In the metallurgical industry, the industrial cardan shaft is the core component of the rolling mill transmission system. Taking the tropical continuous rolling mill as an example, its main drive universal shaft needs to transmit a torque of up to 3000kN · m, and the speed can be adjusted within the range of 0-200rpm. The working environment temperature can reach over 200 ℃. This type of industrial cardan shaft usually adopts SWC heavy-duty cross shaft design, equipped with water cooling or oil mist lubrication system, and the bearings are made of special high-temperature resistant materials. In continuous casting equipment, the industrial cardan shaft is used to drive the fan-shaped roller conveyor, which needs to compensate for the axis deviation caused by the thermal expansion of the casting billet.

In the field of mining machinery, large universal shafts used in equipment such as ball mills and crushers face challenges of large impact loads and high levels of dust. The design adopts a reinforced cross package structure, and the sealing system adopts a multi-layer labyrinth with magnetic sealing, effectively blocking dust intrusion. Some models are also equipped with torque overload protection devices, which automatically slip when the load exceeds the set value, protecting the safety of the transmission system.