LK Flexible Couplings

LK Flexible Coupling is a flexible coupling widely used in mechanical transmission systems, occupying an important position in the industrial field with its unique elastic element design. This type of coupling compensates for the relative displacement between the two shafts through the deformation of the intermediate elastic body, while also having the functions of shock absorption, buffering, and noise reduction.

Compared with traditional rigid couplings, LK Flexible Couplings can effectively absorb and alleviate additional loads caused by misalignment, protecting the transmission system from damage. Its design balances the requirements for torque transmission and system flexibility, making it an essential key component in modern mechanical transmission systems.

Structural composition of LK Flexible Coupling

Basic structural elements

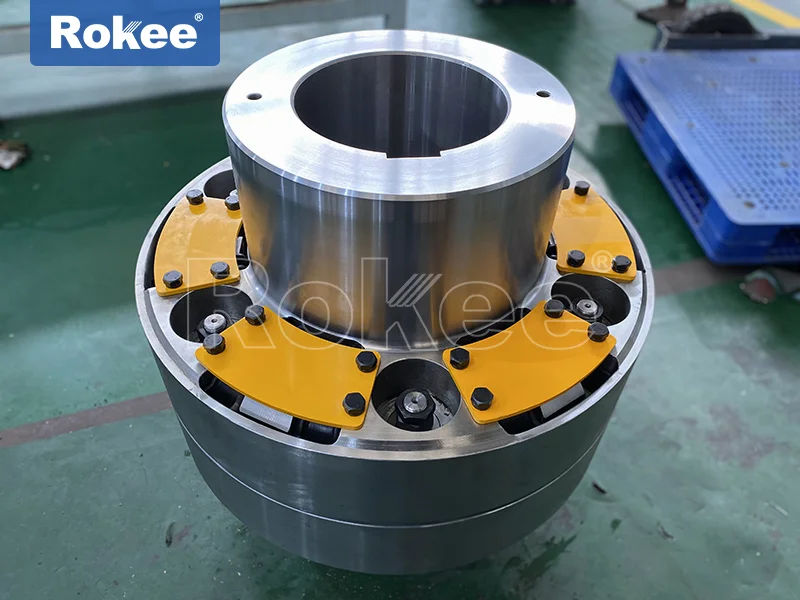

The LK Flexible Coupling mainly consists of three core components:

Half coupling: usually made of metal material (cast iron or steel), connected at both ends to the driving shaft and the driven shaft respectively

Elastic block: made of specially formulated rubber or polyurethane material, it is the core functional component of the coupling

Connection components: including bolts, nuts and other fasteners, used to fix the elastic block and half couplingSpecial design of elastic block

The elastic block of LK coupling adopts a unique "plum blossom" or "star shaped" cross-sectional design, which has the following advantages:

Provide multi-directional elastic deformation capability

Uniform distribution of stress, extending service life

Increase contact area and enhance torque transmission capability

Easy to install and replace

Working principle of LK Flexible Coupling

Torque transmission mechanism

When the drive shaft rotates, the torque is transmitted to the elastic block through the half coupling, and the elastic block undergoes elastic deformation and transmits the torque to the other half coupling, ultimately driving the driven shaft to rotate. This method of transmitting power through elastic deformation can effectively absorb impacts and vibrations.Displacement compensation function

LK Flexible Coupling can compensate for three basic types of shaft alignment errors:

Radial displacement: up to 0.5-3mm (depending on the model)

Angular displacement: typically allows for a deviation angle of 1 ° -3 °

Axial displacement: limited axial displacement compensation capability

This multi-directional compensation capability makes LK couplings particularly suitable for situations where installation accuracy is difficult to guarantee or displacement may occur during operation.

Performance advantage

Excellent shock absorption performance: Rubber elastomer can absorb up to 30% of vibration energy

No lubrication required: simplifies maintenance procedures and reduces operating costs

Electrical insulation: prevents current from conducting between two axes

Buffer start: Slowing down the impact during startup and shutdown

Wide temperature adaptation range: Standard models can operate in environments ranging from -30 ℃ to+80 ℃

LK Flexible Couplings are widely used in the following fields:

Pump equipment: centrifugal pumps, plunger pumps, etc., to reduce water hammer effects

Fan system: cooling tower fan, industrial exhaust fan, etc

Conveyor machinery: belt conveyor, screw conveyor

Power generation equipment: diesel generator sets, small water turbines

Food processing machinery: mixers, mixing equipment

Choosing a suitable LK Flexible Coupling requires consideration of:

Transmission torque requirements

Shaft diameter size

Working environment temperature

speed range

Mean square error situation

Space constraints

Correct installation steps

Clean the shaft end and keyway, remove burrs

Apply an appropriate amount of lubricating oil to the inner hole and shaft of the half coupling

Install the half coupling using hot installation or hydraulic method to avoid knocking

Preliminary alignment of the two halves of the coupling, leaving appropriate clearance

Install the elastic block and evenly tighten the connecting bolts

Perform final alignment inspection and control the radial deviation within 0.2mm

Key points of maintenance and upkeep

Regularly inspect the elastic block for cracks, hardening, or permanent deformation

Check the tightening status of bolts to prevent looseness

Avoid contact with substances such as oils, solvents, etc. that may corrode elastomers

Pay attention not to exceed the rated range of working temperature

When replacing elastic blocks, they should be replaced in groups to maintain consistent performance

LK Flexible Couplings with their reliability and economy, will continue to play an important role in the industrial transmission field, providing efficient and smooth power transmission solutions for various mechanical equipment.