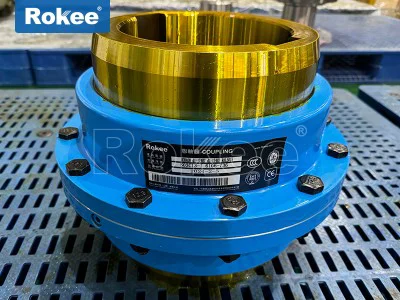

Face Gear Couplings

Face gear coupling is a mechanical device that transmits torque through gear meshing and belongs to the category of flexible couplings.

Core structure:

External gear shaft sleeve: fixed on the driving shaft or driven shaft, usually with straight teeth or drum teeth.

Internal gear ring: combined with the outer sleeve to form a meshing pair, allowing for a certain degree of shaft deviation compensation.

Sleeve components: divided into two forms: flange sleeves (connected by bolts) and continuous sleeves (surrounding the shaft end as a whole), with materials available in metal or nylon.

According to tooth design, it can be divided into:

Straight tooth type: simple structure, limited compensation ability.

Drum shaped tooth profile: The tooth tip is designed with a spherical surface, allowing for greater angular displacement and increasing load-bearing capacity by 15% -30%. It is widely used in heavy-duty scenarios.

Working principle and performance characteristics

Power transmission: Synchronous rotation is achieved through precise meshing of inner and outer teeth, with a transmission efficiency of up to 99.7%.

Deviation compensation: It can absorb axial, radial, and angular displacements, reducing installation accuracy requirements.

Load capacity: Wide torque range, up to 4500kN · m, suitable for low-speed heavy-duty (such as metallurgical rolling mills) or high-speed precision (such as gas turbines) scenarios.

Lubrication requirement: Regular maintenance with lithium based grease is required to avoid tooth wear and overheating.

Typical application areas

Heavy industry: steel rolling mills, mining crushing equipment.

Energy and ships: generator shaft system, offshore platform transmission system.

General machinery: equipment such as pumps and compressors that require high torque synchronous transmission.

Selection factors:

Consider torque load, speed, deviation type (parallel/angle), ambient temperature, and lubrication conditions.

Fault prevention:

Regularly check the contact area of the tooth surface (tooth height ≥ 50%, tooth width ≥ 70%).

Monitor vibration and noise to prevent abnormal wear caused by poor lubrication.

Dynamic balance verification is required in high-speed scenarios to avoid failure caused by centrifugal force.

From the above analysis, it can be seen that the face gear coupling occupies an irreplaceable position in complex industrial transmissions due to its high load-bearing capacity and high compensation ability. Reasonable selection and maintenance can significantly extend the service life of the equipment.