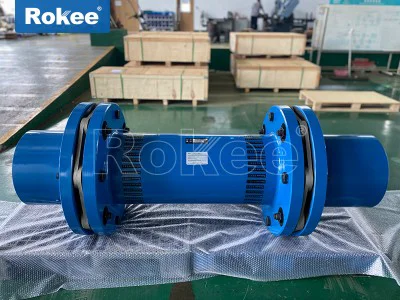

Steel Laminae Couplings

Steel laminae coupling is a flexible coupling device that compensates for shaft deviation through elastic deformation of metal diaphragms. Its core is composed of a membrane group composed of multiple layers of stainless steel thin plates stacked together, and the two halves of the coupling are connected by bolts in a staggered manner, achieving torque transmission without lubrication. The flexible design of the membrane can absorb axial, radial, and angular displacements, making it suitable for high-speed, high-temperature, and corrosive environments.

Single/Double Diaphragm Structure

Single membrane type: simple structure, suitable for low eccentricity scenarios, high torsional stiffness but limited compensation capability.

Double diaphragm type (such as SJM type): By coordinating the deformation of two sets of diaphragms, multi-directional deviation can be compensated simultaneously, and the angular displacement capacity is twice that of a gear coupling. It is suitable for long wheelbase transmission (such as fans and compressors).

Special type

Expansion sleeve type (such as JZM type): using keyless expansion sleeve fixation to avoid shaft damage, suitable for heavy machinery (metallurgy, mining equipment).

Step type: enhances torsional stiffness, suitable for high-power transmission (such as generator sets).

Performance advantage of steel laminae coupling

High transmission efficiency: up to 99.86%, no rotational clearance, precise transmission of speed.

Environmental adaptability: acid and alkali resistant, corrosion-resistant, can operate for a long time in oil contaminated, high or low temperature environments.

Maintenance free design: No wear parts, with a lifespan of over 10 years, significantly reducing downtime costs.

Vibration reduction and noise reduction: Metal diaphragms absorb vibrations, reduce bearing loads, and are suitable for precision machinery (such as servo systems).

Key selection points

Select the number of diaphragm groups based on torque (range 10Nm~810000 Nm), speed, and deviation.

J1 type is preferred for shaft hole type to improve interchangeability, and when the shaft diameter is different, the larger shaft diameter should be selected.

Installation steps

Clean the shaft end and apply lubricant, gradually tighten the bolts diagonally (3 times to rated torque).

Control the gap between the flange and the diaphragm (0.20-0.30mm) to avoid axial overload.

Common faults

Reason for abnormal noise: Loose bolts, excessive axial displacement (needs to be adjusted to within 1/3 of the allowable value).

Membrane fracture: caused by long-term overload or accumulated fatigue due to angular deviation.

Maintenance suggestions for steel laminae coupling

Regularly check the pre tightening force of bolts, and apply molybdenum disulfide lubricant between the diaphragms to reduce micro motion wear.

It is recommended to install protective covers on high-speed equipment to prevent debris from splashing.

Application scenarios of steel laminae coupling

Industrial field: Heavy duty equipment such as chemical pumps, air compressors, and rolling mills.

Energy sector: wind power gearbox, turbine transmission system.

Steel laminae coupling with their excellent reliability and adaptability, are gradually replacing traditional gear couplings and becoming the preferred solution for modern industrial transmission. Proper selection and installation are the key to maximizing its performance. It is recommended to consult professional manufacturers for customized design based on specific working conditions.