Teeth Couplings

Teeth couplings achieve power transmission through gear meshing and have high torque bearing and deviation compensation capabilities.

They can be divided into three types:

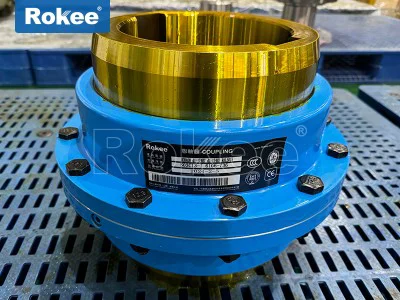

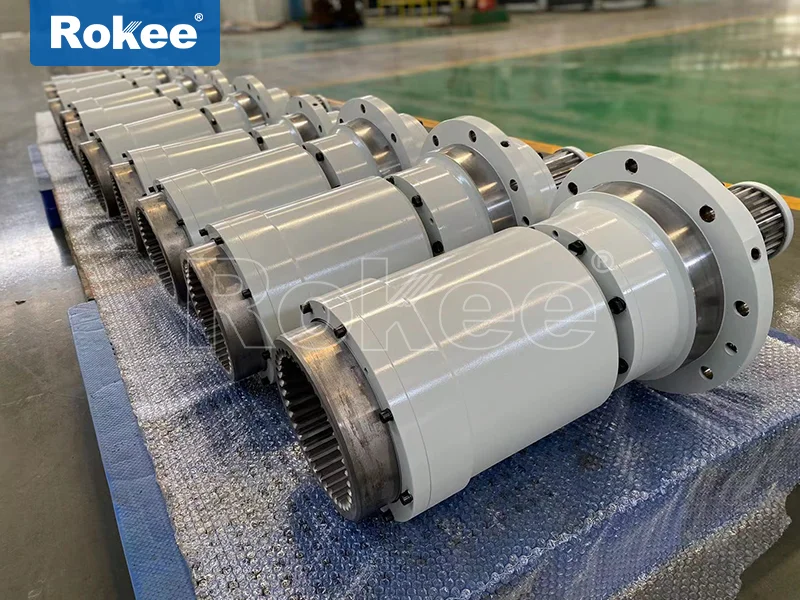

Drum gear coupling

Spherical tooth design: The outer gear shaft sleeve adopts a spherical drum structure, with a 50% increase in tooth clearance compared to straight teeth, and an angular displacement compensation capability of 1 ° 30 '

Adopting a three-dimensional curved tooth design, allowing for an angle deviation of ± 1.5 °, the torque is increased by 40% compared to traditional straight tooth structures

Typical application: Metallurgical rolling mill

Nylon internal gear coupling (such as NL series)

Material innovation: using glass fiber reinforced nylon composite material, with a wear resistance coefficient of 0.12 (under dry friction conditions), suitable for temperature range of -40 ℃~120 ℃

Nylon inner gear sleeve for vibration and noise reduction, with a nominal torque coverage of 40N · m~3150N · m (NL1-NL10 models)

Advantages: lubrication free, corrosion-resistant, suitable for water pumps and hydraulic systems

Elastic pin toothed coupling

Buffer design: The elastic modulus of the nylon column pin is 3.2GPa, which can absorb 15% of the impact load (reducing vibration by 60% compared to rigid couplings)

Nylon column pin buffers impact load, with axial compensation of ± 0.7mm

Economical selection, commonly seen in conveyor and fan equipment

Teeth coupling is a mechanical connection device that transmits torque through the meshing of internal and external gears, and belongs to the category of rigid movable couplings. This type of coupling occupies an important position in modern industrial transmission systems due to its excellent torque transmission capability, good compensation performance, and high reliability.

The core of a toothed coupling lies in its unique gear meshing design. When the driving shaft rotates, power is transmitted to the driven shaft through the meshing effect of the external gear and the internal gear, while allowing for certain radial, axial, and angular deviations between the two shafts. Unlike ordinary couplings, the tooth profile design of teeth couplings enables them to maintain efficient power transmission even in the presence of misalignment.

A typical teeth coupling consists of the following key components:

External gear sleeve: usually installed at the shaft end, with an external tooth structure

Internal gear ring: an internal gear component that matches with an external gear sleeve

Connecting flange: used to fix and connect various components

Sealing device: prevents lubricant leakage and contamination from entering

Fasteners: Ensure that all components are securely connected

Teeth couplings exhibit multiple outstanding performances in industrial applications:

High torque density: The ability to transmit torque per unit size is superior to most types of couplings

Good compensation capability: can simultaneously compensate for radial, axial, and angular deviations

High transmission efficiency: usually up to 98-99.5%

Long service life: can reach tens of thousands of hours with proper maintenance

Smooth operation: The gear meshing characteristics make the transmission smoother

The widespread application of teeth couplings is reflected in multiple industries:

Heavy industry: rolling mills, mining machinery, heavy-duty machine tools

Energy sector: generator sets, turbomachinery, compressors

Shipbuilding industry: propulsion systems, auxiliary machinery

Petrochemical industry: pump sets, compressors, mixing equipment

Transportation: locomotive transmission, special vehicles

Reasonable selection of teeth couplings requires consideration of key factors:

Transmission torque magnitude and characteristics (constant/impact)

Shaft diameter size and connection method

Expected deviation range of two axes (radial, axial, angular)

Working environment (temperature, corrosiveness, humidity)

Speed range and critical speed

Space limitations and installation methods

As a key component in the industrial transmission field, the technological development of teeth couplings will continue to meet the modern industrial demand for efficient and reliable transmission, especially in high-power, heavy-duty, and harsh environmental applications, maintaining an irreplaceable position.