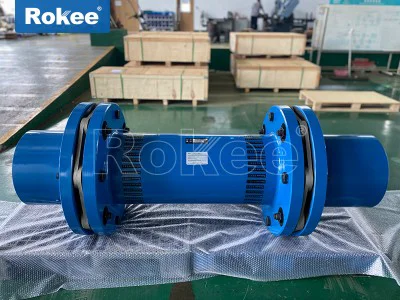

Shim Pack Couplings

Shim pack coupling is a high-performance metal elastic element flexible coupling, which is composed of several sets of stainless steel thin plates made of membranes connected to the two halves of the coupling through bolts in a staggered manner. Each group of membranes is composed of several stacked sheets, and the relative displacement between the two connected axes is compensated by the elastic deformation of the membranes. This design makes diaphragm couplings an ideal replacement for gear couplings and other traditional couplings today.

According to their structural and functional characteristics, shim pack couplings can be divided into various types:

Single shim pack coupling: composed of one diaphragm and two shaft sleeves, with a relatively simple structure, suitable for situations with low compensation requirements.

Double shim pack coupling: consisting of two diaphragm components, it has stronger deviation compensation capability and can simultaneously bend in different directions to compensate for eccentricity.

JZM heavy-duty shim pack coupling: specially designed for heavy-duty machinery, with higher torque carrying capacity and environmental adaptability.

SJM type double shim pack coupling: adopting a special structural design, suitable for harsh working conditions such as high temperature, high speed, and corrosive media.

In addition, according to different connection methods, shim pack couplings can be divided into different series such as keyway connection type, expansion sleeve connection type, etc., to meet the needs of various shaft connections. These classifications reflect the specialized development of membrane couplings in different industrial application scenarios, providing users with diverse options.

The core structure of a shim pack coupling consists of three major components: the coupling body, the diaphragm assembly, and the connecting bolts. The coupling body is usually divided into two halves, connected to the driving shaft and the driven shaft respectively; The membrane group is composed of multiple stainless steel thin plates stacked together and fixed between the two halves of the coupling by high-strength bolts in a staggered manner. This structure may seem simple, but it contains intricate mechanical design principles.

The working principle of shim pack couplings is based on the fundamental principle of metal elastic deformation. When the driving shaft transmits torque, the torque acts on the diaphragm group through the bolt, causing elastic deformation of the diaphragm and transmitting the torque to the driven shaft. During this process, the elastic deformation of the membrane can effectively compensate for axial, radial, and angular deviations between the two axes.

Specifically:

Axial displacement compensation: When two axes undergo displacement along the axis direction, the diaphragm will bend and deform to adapt to this change.

Radial displacement compensation: For cases where the two axis centerlines do not coincide, the diaphragm can absorb radial deviation through its own deflection.

Angular displacement compensation: When there is an angle between the two axes, the diaphragm group can maintain torque transmission through asymmetric deformation.

It is worth noting that the compensation capability of shim pack couplings is closely related to their structural design. The double shim pack coupling has stronger deviation compensation capability compared to the single diaphragm type, because the two sets of diaphragms can deform in different directions simultaneously, forming a more effective compensation mechanism. In addition, the thickness, material, and number of layers of the diaphragm itself directly affect the compensation performance and load-bearing capacity of the coupling.

The reason why shim pack couplings can be widely used in many industrial fields is due to their excellent technical performance and significant advantages in use.

Compared with traditional couplings, shim pack couplings exhibit a series of outstanding features:

High precision transmission: The shim pack coupling has no rotational clearance, with a transmission efficiency of up to 99.86%. It can accurately transmit speed and operate without slip, meeting the strict requirements of precision mechanical transmission.

Environmental adaptability: It can work stably within the temperature range of -80 ℃ to+300 ℃ and withstand corrosive media such as acid and alkali, suitable for harsh working conditions such as chemical and metallurgical industries.

Maintenance free design: No lubrication or sealing structure is required, reducing maintenance workload and operating costs, while avoiding pollution problems caused by lubricant leakage.

Excellent dynamic performance: It has a significant vibration reduction effect, can effectively absorb vibrations and impacts in the transmission system, operates without noise, and extends the service life of the equipment.

Compact and lightweight: simple structure, light weight, small volume, easy installation and disassembly, no need to move the machine to complete the installation and disassembly work (referring to the type with intermediate shaft).

From the technical parameters, the compensation capability of the shim pack coupling is significantly better than that of the traditional gear coupling. Its angular displacement compensation capability can reach twice that of the gear coupling, and the reaction force generated during radial displacement is smaller. For example, a certain model of shim pack coupling can withstand angular deviations of up to 1.5 degrees while generating lower bearing loads in the servo system. These characteristics make shim pack couplings particularly suitable for medium to high speed and high-power transmission scenarios, becoming the preferred component for modern industrial transmission systems.

Shim pack couplings have been widely used in many industrial fields due to their excellent performance characteristics. Its application scope covers various transmission systems from general machinery to special working condition equipment, demonstrating strong adaptability and reliability.

In the field of general industrial equipment, shim pack couplings are widely used in:

Pump equipment: especially high-power water pumps and chemical pumps, shim pack couplings can effectively resist the influence of corrosive media.

Fan system: including centrifugal fans, axial fans, etc., using the damping characteristics of diaphragms to reduce noise and vibration.

Compressor: Various gas compressors use shim pack couplings to achieve efficient and stable power transmission.

Hydraulic machinery: The shim pack coupling, which does not require lubrication, is very suitable for the cleaning requirements of hydraulic systems.

In terms of heavy machinery and special equipment, shim pack couplings play an irreplaceable role:

Mining machinery, such as crushers and ball mills, utilize the high torque transmission capability of shim pack couplings.

Metallurgical equipment such as rolling mills and continuous casting machines rely on the heat resistance of shim pack couplings in high-temperature environments.

Oil drilling and production: The key equipment on the drilling platform adopts shim pack couplings to resist harsh working conditions.

Generator set: including various high-power transmission systems in thermal, hydraulic, and nuclear power plants.

Of particular note is the increasingly widespread application of shim pack couplings in high-tech fields

Aviation power: The helicopter transmission system adopts special shim pack couplings to meet the requirements of lightweight and high reliability.

Ship propulsion: shim pack couplings are used in the ship's power system to connect the main engine and propeller, adapting to shaft deformation.

High speed railway: The transmission system of high-speed trains uses shim pack couplings to ensure stability during high-speed operation.

Robot technology: Precision shim pack couplings provide seamless power transmission for industrial robots.

These diverse applications fully demonstrate the important position of shim pack couplings as basic transmission components, and their technological development continues to drive the improvement of equipment performance in various industries.

The correct selection of shim pack couplings is a crucial step in ensuring the reliable operation of the transmission system. During the selection process, multiple factors need to be considered, including meeting basic transmission requirements and adapting to specific working conditions. The following are the main points for selecting shim pack couplings:

Basic parameter determination:

Torque characteristics: Determine the rated torque, peak torque, and starting torque according to the requirements of the transmission system. The rated torque of the coupling should be greater than the maximum working torque of the system and leave a certain safety margin.

Speed range: shim pack couplings with different structures have their applicable speed ranges, and products that have undergone precision dynamic balancing should be selected for high-speed applications.

Shaft diameter size: The aperture of the coupling must match the shaft diameter. When the main and driven end shaft diameters are different, the model should be selected according to the larger shaft diameter.

Displacement compensation: Evaluate the possible axial, radial, and angular deviations of the system and select a coupling type with sufficient compensation capability.

Consideration of adaptability to working conditions:

Environmental conditions: For high temperature, low temperature, or corrosive environments, special materials (such as stainless steel) should be selected for shim pack couplings.

Vibration and impact: For systems with strong vibration or impact loads, couplings with good vibration reduction performance should be selected.

Space limitations: In situations where installation space is limited, compact shim pack couplings become an ideal choice.

Maintenance requirements: For equipment that is difficult to maintain frequently, priority should be given to maintenance free shim pack couplings.

Installation coordination requirements:

Shaft hole form: It is recommended to use the standard shaft hole form specified in GB/T3852 (such as J1 type) to improve universality and interchangeability.

Alignment accuracy: Although shim pack couplings have the ability to compensate for deviations, it is still necessary to improve alignment accuracy as much as possible during installation to extend their service life.

Bolt tightening: It is necessary to use a torque wrench to tighten the bolts according to the specified torque, ensuring a reliable connection and not damaging the diaphragm.

It is particularly important to note that shim pack couplings are highly sensitive to installation errors. Although it can compensate for a certain degree of deviation, installation errors beyond the allowable range can lead to premature fatigue damage of the diaphragm. Generally speaking, the angular deviation should be controlled within 1.5 degrees, the radial deviation should not exceed 0.2mm, and the axial deviation should be within 0.3mm. In practical applications, controlling the deviation within one-third of the allowable value can significantly extend the life of the coupling.

The correct installation of shim pack couplings is an important prerequisite for ensuring their performance and extending their service life. Compared with ordinary couplings, shim pack couplings have higher requirements for installation processes and need to follow standardized installation procedures and operating methods.

Detailed installation steps:

Preparation in advance: Clean the surface of the shaft end and the inner hole of the coupling, check the dimensional accuracy and surface quality of the keyway and other mating parts.

Shaft hole fit: Install the coupling onto the shaft. If the hole diameter is too tight, use a special tool to press it in. It is strictly prohibited to strike it directly with a hammer.

Centering adjustment: use precision measuring tools such as dial indicator to detect the radial and end face runout of the two coupling halves to ensure that the coaxiality is within the allowable range.

Bolt tightening: Tighten the bolts in stages according to diagonal order, first pre tighten with 1/4 of the specified torque, then increase to 1/2, and finally reach the full value.

Final inspection: After installation, manually turn the wheel to check for any jamming and confirm that the clearances between various parts meet the requirements.

Key points of maintenance and upkeep:

Regular inspection: During the initial operation, the bolt tightening status should be checked daily, and any looseness should be dealt with immediately; After stable operation, the inspection cycle can be extended.

Diaphragm state: Check the diaphragm for cracks, deformations, and other damages by observing the holes or disassembling it, and replace damaged parts in a timely manner.

Environmental control: Keep the area around the coupling clean, avoid the accumulation of corrosive substances, and add protective covers in harsh environments.

Vibration monitoring: Regularly check the vibration value of the coupling. Abnormal vibration often indicates poor alignment or component damage.

Common troubleshooting:

Abnormal noise: Possible causes may include loose bolts, damaged diaphragms, or excessive alignment deviation. The machine should be stopped for inspection.

Increased vibration: In most cases, it is caused by changes in the alignment state and requires re alignment; It may also be caused by membrane fatigue.

Temperature rise: caused by abnormal friction of bearings or couplings, check the alignment and lubrication status.

Diaphragm fracture: Usually caused by long-term overload or fatigue use, the diaphragm needs to be replaced and the system load checked.

It is worth noting that although membrane couplings are maintenance free, they still require regular inspection. It is recommended to conduct a comprehensive inspection every 6-12 months of operation, and shorten the inspection cycle under harsh conditions such as high temperature and high speed. Proper installation and maintenance not only ensure stable operation of the transmission system, but also extend the service life of the shim pack coupling to more than 10 years, significantly reducing equipment lifecycle costs.

In the future, with the advancement of Industry 4.0 and intelligent manufacturing, shim pack couplings will develop towards higher precision and intelligence. The application of digital design platforms and intelligent manufacturing systems will shorten the product development cycle, improve production efficiency and consistency quality. At the same time, the popularization of green manufacturing concepts has prompted enterprises to pay more attention to the environmental friendliness of their products throughout their entire lifecycle, and these trends will profoundly affect the development direction of membrane coupling technology and the market.