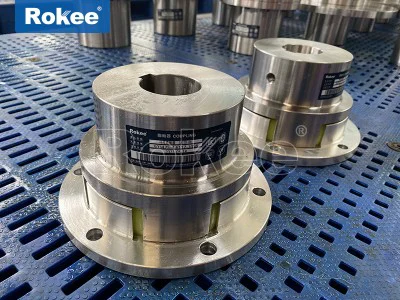

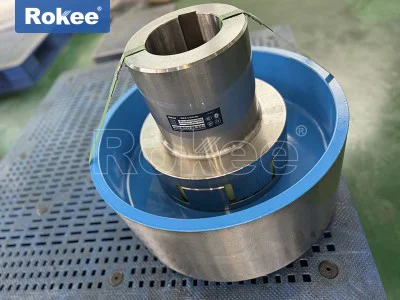

Claw Couplings

Claw coupling is a flexible coupling widely used in industrial machinery transmission systems, occupying an important position in modern mechanical engineering with its unique structure and reliable performance. This type of coupling consists of two claw shaped end flanges made of metal or polymer and an intermediate elastic body (called a "spider"), which transmits torque through the engagement between the claws and the elastic body.

The working principle is based on a simple mechanical meshing principle: when the drive shaft rotates, the claw at the active end pushes the claw at the passive end by compressing the elastic body "spider", thereby achieving power transmission. Elastic components not only transmit torque during operation, but also effectively absorb vibration, compensate for axial, radial, and angular deviations, and protect connected equipment from the effects of impact and vibration.

Core structural characteristics of claw coupling

Claw shaped flange design: usually made of high-strength cast iron, steel or aluminum alloy, with 6-24 claws commonly used. Claw shaped design allows for a certain degree of deflection while maintaining torque transmission efficiency.

Elastic body "spider": As the core buffering element of the coupling, the material is mostly polyurethane, Hytrel or natural rubber. Elastic bodies with different hardness can meet the needs of different working conditions.

Compact construction: Compared to other types of couplings, the claw design structure is more compact, especially suitable for applications with limited space.

Maintenance free feature: Most claw couplings are designed as closed structures that do not require lubrication, significantly reducing maintenance costs and usage complexity.

The outstanding performance advantages of claw type couplings

Vibration damping capability: Elastic components can absorb up to 30% of vibration energy, effectively protecting the transmission system

Deviation compensation performance: Typical parameters are axial deviation ± 0.5mm, radial deviation 0.4mm, and angular deviation 1 °

Torque transmission efficiency: can reach over 98% under rated operating conditions

Overload protection function: When the torque exceeds the design value, the elastic body will be damaged first, protecting expensive equipment

Electrical insulation characteristics: Non metallic elastomers provide excellent electrical insulation performance

Typical application areas of claw couplings

Industrial automation equipment: widely used in precision transmission systems such as CNC machine tools, packaging machinery, textile machinery, etc

Pump equipment: particularly suitable for centrifugal pumps, gear pumps, and other occasions that require vibration isolation

Ventilation system: effectively reducing vibration transmission in fan drive

Food and pharmaceutical machinery: Material selection that meets hygiene requirements meets special industry standards

Servo Drive System: High precision models for demanding motion control applications

Selection considerations:

Torque demand (rated torque and peak torque)

Axis diameter size matching

Working environment (temperature, humidity, chemical exposure)

Speed range (not exceeding the limit of elastic material)

Deviation compensation requirements

Installation precautions:

Ensure that the interference fit between the shaft and the coupling meets the standard

Use specialized tools for installation to avoid damaging the elastic body by knocking

Control the centering accuracy within the allowable deviation range

Check the fastening status after initial operation

Regularly check the wear of the elastomer (recommended every 2000 working hours)

Claw couplings continue to play an irreplaceable role in the field of industrial transmission due to their excellent comprehensive performance and reliability. With the advancement of materials science and manufacturing technology, its application scope will further expand and its performance will continue to improve.