LX Star Couplings

The LX star coupling as an outstanding representative of the new generation of elastic couplings, has been widely used in the field of industrial transmission due to its unique structural design and superior performance characteristics. This type of coupling uses star shaped elastic elements as buffering media, which can effectively absorb and compensate for various deviations while transmitting torque, providing a reliable transmission solution for modern mechanical equipment.

Compared with traditional couplings, the biggest feature of LX star couplings is its "star shaped" elastic structure, which not only improves the torsional stiffness of the coupling, but also significantly enhances its ability to compensate for axial, radial, and angular deviations. In mechanical transmission systems, LX couplings are highly favored by engineers for their excellent shock absorption performance, low maintenance requirements, and long service life.

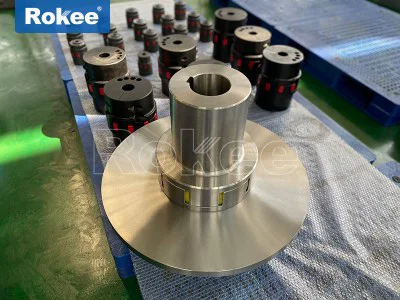

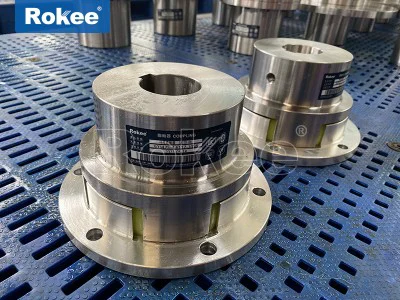

The LX star flex coupling is mainly composed of three key components:

Metal flange: made of high-strength alloy steel or aluminum alloy, providing structural support and connection interfaces

Star shaped elastomer: a specially formulated polyurethane or rubber material with high elasticity and wear resistance

Tightening system: including bolts, nuts, etc., to ensure reliable connection between the coupling and the shaft end

The LX star coupling achieves power transmission and deviation compensation through its unique star shaped elastic body:

Torque transmission: Power is transmitted from the drive shaft to the elastic body through the flange, and then to the driven end

Deviation compensation: The elastic deformation of star shaped elastomers can absorb axial displacement (± 0.5-3mm), radial displacement (0.2-1.5mm), and angular deviation (1 ° -3 °)

Shock absorption and buffering: The damping characteristics of elastic materials effectively absorb impact loads and vibrations, protecting the transmission system

During operation, the LX star flexible coupling exhibits multiple outstanding performances:

Self centering ability: The deformation characteristics of the elastic body give the coupling a certain degree of automatic centering function

Backless transmission: The pre compressed elastic material ensures no clearance during the transmission process, making it particularly suitable for precision transmission

Overload protection: When the torque exceeds the rated value, the elastic body can slide to avoid equipment damage

Modern LX star couplings have excellent performance:

Transmission efficiency: up to 99% or more (with no lubrication design to reduce energy loss)

Service life: up to 20000-50000 hours under normal operating conditions

Maintenance cycle: maintenance free design or recommended to check the condition of the elastomer every 2 years

The LX star coupling has formed a complete series of products:

Micro series: outer diameter 30-80mm, suitable for precision instruments and small equipment

Standard series: outer diameter 80-300mm, most widely used in industrial applications

Heavy duty series: outer diameter 300-600mm, meeting high torque requirements

Customized Series: Non standard sizes can be designed according to special requirements

LX star couplings cover almost all industrial transmission fields:

Automation equipment: robotic arms, CNC machine tools, packaging machinery

Power transmission: connection of motor, reducer, and pump unit

Transportation machinery: conveyor belts, lifting equipment, rail transit

Energy equipment: wind power generation, hydroelectric power generation units

Special Machinery: Ship Propulsion, Mining Machinery, Metallurgical Equipment

Although the LX star coupling is designed to be maintenance free, proper maintenance can extend its lifespan

Regular inspection: Check the wear of the elastic body and the tightening status of the bolts every 6 months

Cleaning advice: Use neutral cleaning agents to avoid solvent corrosion of elastomers

Storage conditions: Avoid direct sunlight and stay away from ozone sources

With the advancement of industry and intelligent manufacturing, LX flexible couplings will develop towards higher performance, intelligence, and environmental friendliness, continuing to play a key role in the field of industrial transmission.