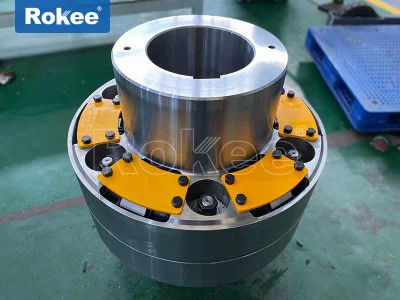

Gear Type Safety Couplings

Gear type safety coupling is a special mechanical transmission device that transmits torque through gear meshing and has overload protection function. When the transmission system experiences abnormal situations exceeding the preset torque, the coupling can automatically disconnect or slip, thereby protecting the mechanical equipment from damage. This type of coupling is widely used in various industrial transmission systems, especially in working environments that require high precision and reliability.

The core working principle of the gear safety coupling is based on the combination of gear meshing transmission and safety disengagement mechanism.

Typical structures include:

Drive end and driven end gears: precision machined involute gears are used to ensure smooth torque transmission

Safety mechanism: usually set with spring preload force, automatically disengages when the torque exceeds the set value

Reset mechanism: After troubleshooting, it can be manually or automatically reset to restore transmission function

The uniqueness of this type of coupling lies in the perfect combination of high transmission efficiency (up to 98% or more) and overload protection, solving the problem of insufficient or excessive protection of traditional couplings.

Compared to other types of couplings, toothed safety couplings have the following significant advantages:

Accurate protection: The disengagement torque can be precisely set, and the protection threshold is stable and reliable

Quick response: millisecond level response speed, effectively preventing damage caused by impact loads

Maintenance free design: Closed structure, long-lasting lubrication with grease, long maintenance cycle

Multiple protection: Some models integrate functions such as torsional damping and electrical isolation

Diagnostic function: The trip status can be visualized or an electrical signal can be output for easy fault diagnosis

Gear type safety couplings are widely used in the following fields:

Wind power industry: used for connecting generators and gearboxes to prevent grid impact

Metallurgical equipment: overload protection for heavy equipment such as rolling mills and continuous casting machines

Mining machinery: transmission system protection for crushers, ball mills and other equipment

Shipbuilding industry: secure connection between propulsion system and main engine

Petrochemical equipment: Overload protection for key equipment such as compressors and pumps

The correct selection of a gear safety coupling requires consideration of the following factors:

Load characteristics: constant load, impulse load, or periodic load

Environmental conditions: temperature, humidity, corrosiveness, etc

Installation space: radial and axial dimension limitations

Transmission accuracy: Is it necessary to compensate for various deviations

Maintenance requirements: lubrication method, inspection cycle, etc

It is recommended to consult professional technicians for detailed calculations and selection to ensure that the coupling matches the system.

Although the toothed safety coupling is designed as a maintenance free type, proper maintenance can extend its service life:

Regular inspection: Check the lubrication status every 6-12 months

Torque verification: Verify the set value of the disengagement torque once a year

Cleaning and maintenance: Keep the outside of the coupling clean to prevent foreign objects from entering

Lubrication management: Supplement or replace lubricating grease according to the manufacturer's requirements

Status monitoring: Vibration monitoring devices can be installed when conditions permit

As an important component of modern industrial transmission systems, the gear safety coupling's technological innovation will continue to provide reliable guarantees for the safe operation of equipment.