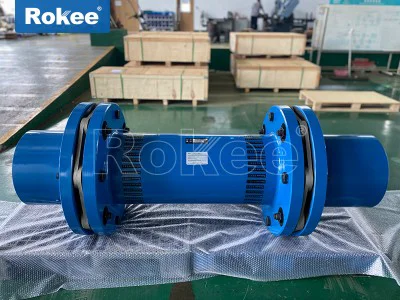

Double Diaphragm Couplings

Double diaphragm coupling is an advanced metal elastic element flexible coupling, which occupies an important position in modern industrial transmission systems with its unique structure and excellent performance.

Double diaphragm coupling is a flexible coupling device with multi-layer stainless steel diaphragm group as the core component, which complies with the mechanical industry standard JB/T9147-1999. Its basic structure consists of the following parts:

Metal diaphragm group: usually made of multiple layers of stainless steel thin plates stacked together, it is the core elastic element of the coupling. Each group of membranes is composed of several stacked pieces, divided into two main types: linkage type and integral piece with different shapes.

Connecting components: including staggered bolt assemblies, flanges, and buffer sleeves. Bolts are usually inserted from the outside of the small hole on the flange, pass through the diaphragm hole, and then exit from the outside of the large hole on the other side of the flange. After fitting with a buffer sleeve and elastic washer, tighten the nut.

Shaft sleeve or hub: used to connect the transmission shaft and diaphragm group, usually designed with different connection methods such as keyway, clamping mechanism or cone sleeve to adapt to various shaft end forms.

The working principle of the double diaphragm coupling is based on the elastic deformation characteristics of the metal diaphragm. When the driving shaft rotates, the torque is transmitted to the diaphragm through the bolt group, and the diaphragm undergoes elastic deformation and transmits the torque to the driven shaft. This design enables it to effectively compensate for the relative displacement between the two axes:

Axial displacement compensation: The diaphragm can undergo bending deformation along the axis direction, absorbing axial installation errors.

Radial displacement compensation: The diaphragm group can generate radial elastic deformation to adapt to the parallel deviation between the two axes.

Angular displacement compensation: The diaphragm can withstand a certain degree of deflection and compensate for the angular deviation between the two axes.

Compared with single diaphragm couplings, the dual diaphragm design significantly improves compensation capability through the synergistic effect of two sets of diaphragms. Single diaphragm couplings are not very suitable for eccentric working conditions, while double diaphragm couplings can bend in different directions simultaneously, more effectively compensating for complex deviations.

The double diaphragm coupling combines multiple excellent performances, making it an ideal choice for many industrial applications:

Excellent transmission performance

High torque rigidity: The static torsional stiffness can reach 450-3400N · m/rad, which can transmit large torque without producing significant torsional angles.

Zero backlash: The metal diaphragm connection ensures seamless transmission, making it particularly suitable for servo systems that require precise position control.

Efficient transmission: With a transmission efficiency of up to 99.86% and minimal energy loss, it outperforms most other types of couplings.Excellent environmental adaptability

Corrosion resistance: The stainless steel membrane and surface treatment give it acid, alkali, and corrosion resistance, making it suitable for harsh environments such as chemical and marine industries.

Wide temperature operation: It can work stably within the temperature range of -80 ℃ to+300 ℃ and adapt to extreme temperature conditions.

Fatigue resistance: Metal elastic components have high strength and long service life, far superior to non-metallic elastic component couplings.Significant operational advantages

Maintenance free design: No lubrication or sealing required, reducing downtime and maintenance costs.

Vibration and noise reduction: The elastic properties of the diaphragm can absorb vibrations and impacts, reducing system noise.

Compact structure: small size, light weight, saving installation space, especially suitable for applications with limited space.Safety and reliability

Overload protection: When the torque exceeds the design value, the diaphragm will undergo significant deformation, providing a certain degree of overload protection.

Failure safety: Even if the diaphragm is damaged, the coupling can usually maintain short-term transmission to avoid sudden equipment shutdown.

Balance performance: After precision dynamic balancing treatment, the maximum speed can reach 6000r/min, suitable for high-speed operation.

Compared with traditional gear couplings, double diaphragm couplings have no relative sliding parts, do not require lubrication and sealing, are basically maintenance free, and are relatively easy to manufacture. They have replaced gear couplings in many applications. In industrialized countries, the application of diaphragm couplings has become very common.

Multiple models and series of double diaphragm couplings have been developed based on specific structures and application requirements, with common classifications including:

Classified by structural form

JMI type diaphragm coupling: Basic double diaphragm coupling, suitable for general transmission applications.

JMIJ type diaphragm coupling: an improved version with an extended intermediate section, which can achieve longer wheelbase connections.

JMII type diaphragm coupling: heavy-duty design, suitable for high torque transmission.

JMIIJ type diaphragm coupling: heavy-duty with extended middle section, meeting the requirements of high torque and long wheelbase.Classified by connection method

Keyway connection type: The most common connection method is to connect the shaft and coupling through keys and keyways.

Expansion sleeve connection type: using the fastening force of the expansion sleeve to achieve connection, suitable for situations where it is inconvenient to process keyways.

Cone sleeve connection type: tight connection is achieved through a conical sleeve, which is easy to install and disassemble.

Clamping type connection: The shaft surface is directly clamped by bolts, which is easy to install and does not damage the shaft surface.Special Design Series

SJM series: designed specifically for high temperature, high speed, and corrosive environments, using special materials and structures.

ZJM series: cone sleeve connection type, especially suitable for occasions that require frequent disassembly.

TJM series: External clamping design, the most convenient installation.

MCSLC series: High precision servo specific type, with extremely high torsional stiffness and positioning accuracy.

Each series of double diaphragm couplings has different torque capacity, speed limit, compensation capability, and size specifications. Users can choose the most suitable model according to their specific application needs. It is worth noting that in most practical applications, the intermediate shaft type design (i.e. double diaphragm structure) is adopted to improve the performance of two axis offset compensation.

Double diaphragm couplings are widely used in many industrial fields due to their excellent performance:

General industrial equipment

Pump equipment, especially high-power chemical pumps, boiler feed pumps, etc., utilize their characteristics of corrosion resistance and good sealing.

Fan system: used for cooling tower fans, industrial ventilation equipment, etc., to leverage its vibration reduction and noise reduction advantages.

Compressor: Provides reliable shaft connections in air compressors and refrigeration compressors.Heavy Industry and Energy

Petroleum machinery: oilfield drilling equipment, oil pumps, etc., utilizing their corrosion resistance and maintenance free characteristics.

Metallurgical equipment: high temperature and heavy load applications such as rolling mills and continuous casting machines.

Generator set: The connection between the steam turbine, water turbine, and generator needs to withstand high speed and high power.Precision and special equipment

Aviation and naval vessels: helicopter transmission system, high-speed power transmission for naval vessels, requiring high reliability and lightweight.

Printing machinery: occasions that require precise transmission and no reverse clearance.

Textile machinery: smooth transmission under high-speed operation.

Servo system: high-precision positioning equipment such as robots and CNC machine tools.Special environmental applications

Chemical equipment: Suitable for chemical pumps, mixing equipment, etc. due to its acid and alkali resistance and anti-corrosion properties.

Mining machinery: provides reliable transmission under harsh working conditions.

Tracked vehicles: Suitable for working environments with high impact and vibration.The double diaphragm coupling is particularly suitable for the following working conditions:

In situations where compensation for significant axis deviation is required

High speed and high-power transmission system

Corrosive or high-temperature environment

Require maintenance free and long-lasting applications

Precision machinery that requires precise transmission

In practical applications, double diaphragm couplings have successfully replaced many traditional couplings, such as hydraulic couplings. For example, in the cooling tower fan system, the motor and fan connected by a double diaphragm coupling after removing the liquid coupling not only transmit large torque, but also automatically correct the concentricity deviation of the shaft system, achieving simple and smooth rotation.

Proper installation and maintenance are key to ensuring optimal performance and extended service life of the double diaphragm coupling.

Installation steps and precautions

Preparation before installation

Clean the shaft end and coupling inner hole, remove oil stains and burrs

Check the integrity of each component to ensure there are no missing or damaged parts

Apply a thin layer of engine oil or lubricant to the inner holes of the shaft and coupling for easy installationShaft alignment adjustment

Use a dial gauge to check the radial and axial deviations of the two axes

Ensure that the deviation is within the allowable range of the coupling (usually radial ≤ 0.2mm, angular ≤ 0.5 °)

When multiple deviations exist simultaneously, the allowable value should be halvedBolt installation

Install the bolts in the correct direction: Insert them from the outside of the small hole on the flange, pass through the membrane hole, and then exit through the large hole on the other side of the flange

Step by step tightening of bolts: First pre tighten the diagonal direction with 1/4 of the specified torque, then apply 1/2 of the torque, and finally tighten with full torque

Use a torque wrench to ensure that the bolt reaches the specified torque (e.g. M5 bolt is usually 7.8N · m)

Check the clearance between the bolt and the flange fitting section (0.20-0.30mm)Gap inspection

Measure the gap between two sets of membranes, which should be the actual thickness of the membranes plus 0.5mm

Too small a gap can lead to installation difficulties and abnormal noise during operation

Excessive clearance can cause excessive deformation of the membrane and shorten its lifespanFinal inspection

Manually rotate the coupling to check for smoothness

Check if all fasteners are secure

If necessary, apply adhesive on the outer surface of the bolt to prevent looseningKey installation parameter control

The clearance between the flange and the diaphragm should be controlled within the range of 0.20-0.30mm

Gap between buffer sleeve and membrane rivet inner hole: 0.5-0.7mm

Axial propulsion position: Record the initial position of the hub on the shaft to ensure correct installation in place

Bolt tightening sequence: Cross tighten in diagonal direction step by step

Key points of maintenance and upkeep

Regular inspection

Recheck the tightening of all bolts after running one shift

Regularly inspect the membrane for cracks, deformation, or corrosion

Monitor the operation sound, abnormal noise may indicate poor alignment or component damageWear and tear protection

Apply solid lubricants such as molybdenum disulfide between the membranes to reduce micro motion wear

Apply anti-wear coating treatment to the surface of the membrane to extend its lifespan

Check for microcracks around the bolt holesOperation precautions

Avoid long-term overload use

Prevent impact loads caused by operational accidents

Install protective covers at hazardous locations to ensure safetyFault handling

Immediately stop the machine for inspection upon discovering any abnormalities

When replacing damaged membranes, they need to be replaced in groups to maintain balance

When severely damaged, the entire coupling should be replaced

Common problems and solutions

Abnormal noise

Reason: Poor shaft alignment, loose bolts, damaged diaphragm

Solution: Re center, tighten bolts, replace diaphragmPremature failure of membrane

Reason: Axis deviation exceeding limit, overload, corrosive environment

Solution: Adjust alignment, check load, and select corrosion-resistant modelsBolt fracture

Reason: Improper installation, fatigue damage, excessive torque

Solution: Install according to specifications, replace regularly, and check torque

Proper installation and maintenance can extend the lifespan of double diaphragm couplings to several years or even longer. Compared to toothed couplings that require regular lubrication and maintenance, the maintenance free feature of double diaphragm couplings can significantly reduce overall operating costs.