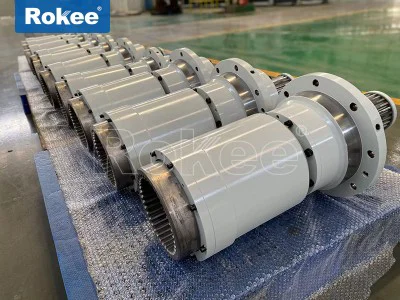

Toothed Couplings

A toothed coupling is a movable rigid coupling, whose core structure consists of internal gear rings with the same number of teeth and flange half couplings with external teeth. According to the different shapes of the external teeth, they are mainly divided into two types: straight teeth and drum teeth. The drum shaped gear coupling makes the outer teeth into spherical surfaces, with the center of the spherical surface located on the gear axis, and has a larger tooth flank clearance than the spur gear coupling. This design brings significant performance advantages.

The toothed coupling achieves torque transmission and rotational motion between the two halves of the coupling through the meshing of inner and outer teeth. When there is relative displacement between the two axes, the tooth surfaces of the inner and outer teeth will periodically slide axially relative to each other. This working characteristic enables the toothed coupling to compensate for a certain degree of axial deviation, including radial, axial, and angular displacement, while transmitting power.

Lubrication and sealing are key conditions for the normal operation of gear couplings. Due to the relative sliding between the tooth surfaces, wear and power loss are inevitable, so the toothed coupling must operate under good lubrication and sealing conditions. Modern high-performance gear couplings often use forced thin oil lubrication systems or segmented grease lubrication structures to reduce tooth wear and extend service life.

Gear couplings can be divided into multiple types based on their gear design, each with unique performance characteristics:

Spur gear coupling

Structural features: The axial tooth blank of the external gear shaft sleeve is processed into a straight line, and both the indexing circle and the tooth root circle are straight lines

Compensation capability: Compensate for relative displacement between two axes by increasing the backlash between the inner and outer teeth, but the compensation amount is limited

Current situation: Products that are gradually being phased out should be avoided as much as possible in new projects

Drum gear coupling

Structural innovation: The tooth tips of the external gear shaft sleeve are processed into circular arcs, and the tooth blanks are formed into spherical surfaces with a drum shaped tooth profile

Performance advantages:

The load-bearing capacity is 15-30% higher than that of the straight tooth type

The allowable angular displacement can reach 1 ° 30 ′, which is 50% higher than the straight tooth type

Improved tooth contact conditions and eliminated edge compression phenomenon

Transmission efficiency up to 99.7%

The outer gear sleeve has a trumpet shaped tooth end, which is easy to assemble and disassemble

When the coupling is working, the relative displacement between the two shafts causes periodic axial sliding of the inner and outer tooth surfaces, which presents two major technical challenges due to the dynamic meshing characteristics:

Wear control: Gradual wear caused by sliding friction on the tooth surface, requiring continuous lubrication

Power loss: meshing friction consumes about 0.3-1.2% of transmission efficiency

The crown gear coupling can transmit torque 15-30% higher than the straight tooth type at the same size, and its angular displacement compensation ability can be increased from 1 ° to 1.5 °. Its service life is extended by 3-5 times in heavy-duty scenarios such as metallurgical rolling mills.