Universal Shaft Couplings

Universal shaft coupling is a key mechanical component used to connect two shafts (active shaft and passive shaft) in different mechanisms. Its main function is to rotate the two shafts together to transmit torque and motion.

Compared with ordinary couplings, the most prominent feature of universal couplings is the ability to achieve reliable transmission when the two shafts are not on the same axis and there is an angle between the axes, with a large angular compensation capability. According to industry standards, the allowable angle between the two axes for universal couplings of different structural types is usually between 5 ° -45 °, which enables them to adapt to various complex installation environments and working conditions.

The basic working principle of universal shaft coupling is based on the theory of spatial linkage mechanism. Taking the most common cross axis universal shaft coupling as an example, it uses a special structure composed of cross axis, bearings, and fork head components to convert the rotational motion of the input shaft into the swinging motion of the cross axis, and then transmit the swinging motion to the output shaft, thereby achieving torque transmission. When there is an angle between the two axes, the cross axis will continuously adjust its angle as it rotates, allowing power to be transmitted continuously. It is worth noting that the single universal shaft coupling may experience speed fluctuations during transmission, and the output shaft speed may vary periodically, which may cause problems in certain precision transmission scenarios. To solve this problem, a double joint form is usually adopted in practical applications, which ensures the synchronization of the main and driven shafts and eliminates the influence of speed fluctuations by reasonably arranging the spatial geometric relationship between the two universal shaft couplings.

From a material perspective, universal shaft coupling couplings are mainly made of high-quality alloy steels such as 45 steel, 45 forged steel, and 40 chromium. These materials have high strength, wear resistance, and fatigue life after appropriate heat treatment. Heavy duty universal couplings will also use alloy cast steel or forged steel parts to meet the demand for high torque transmission. With the advancement of materials science, new materials such as high-strength stainless steel and special alloys have also been applied in some special working conditions, further expanding the application scope of universal shaft couplings.

In terms of its role in industrial transmission systems, universal couplings not only have the basic function of power transmission, but also play an important role in buffering, vibration reduction, and improving the dynamic performance of shaft systems. It can effectively compensate for shaft misalignment caused by manufacturing errors, installation deviations, load deformation, and temperature changes, reduce vibration and noise, and protect the transmission system from damage. Especially in high-speed and heavy-duty power transmission, the reasonable selection and use of universal couplings can significantly improve the reliability and service life of the entire transmission system.

The development of universal couplings has formed various structural types, each with unique performance characteristics and applicable scenarios. According to the transmission principle and structural characteristics, the commonly used universal couplings in the industrial field are mainly divided into three categories: cross shaft type, ball cage type, and ball fork type. Each type can be further subdivided into multiple different forms, forming a series of universal coupling products that meet various industrial needs.

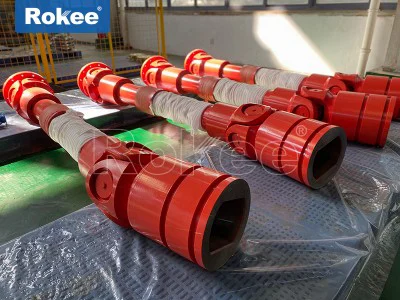

The cross axis universal shaft coupling is currently the most widely used type, and its typical structure consists of two fork joints, a cross axis, and four sets of needle roller bearings. This type of coupling can be divided into various forms, such as SWC type integral fork head, SWP type partial bearing seat, and SWZ type integral bearing seat, according to the different designs of bearing seat and cross head. The main advantages of the cross axis universal shaft coupling are its simple and reliable structure, high load-bearing capacity, and easy maintenance, making it particularly suitable for heavy-duty and low-speed working conditions. For example, in metallurgical rolling mill equipment, the SWC heavy-duty universal shaft coupling has a rotating diameter of up to 1600mm, a torque transmission distance of over 30 meters, and a nominal torque of up to 8000kN · m. However, this type of coupling experiences speed fluctuations during transmission and must be used in pairs and arranged correctly to ensure constant speed transmission. At the same time, its allowable axis angle usually does not exceed 15 ° -20 °, which may be limited in some large angle transmission scenarios.

The ball cage universal shaft coupling achieves true constant speed transmission through precise ball path design and steel ball arrangement, fundamentally solving the problem of speed fluctuations. The ball cage coupling consists of key components such as a spherical outer ring, a star shaped inner ring, a cage, and a force transmitting steel ball. The centers of all steel balls are always located on the bisector of the angle between the two axis lines, ensuring synchronous rotation of the input and output shafts. According to structural characteristics, ball cage couplings can be divided into two categories: fixed type (such as disc, cup, bell, cylinder) and sliding type (such as DOX series). Compared with the cross axis type, the ball cage universal shaft coupling has significant advantages such as high transmission efficiency (up to 98% -99.8%), large swing angle range (up to 75 °), compact structure, and good dynamic balance performance. It is particularly suitable for high-speed precision transmission applications, such as machine tools, packaging machinery, textile machinery, and other equipment. But its manufacturing accuracy requirements are extremely high, the cost is relatively high, and the requirements for sealing and lubrication are also more stringent.

The ball fork universal shaft coupling is another common type of constant velocity universal shaft coupling, which has a relatively simple structure and is mainly composed of two fork shaped parts and a force transmitting steel ball. Compared with the cage type, the fork type has a larger load-bearing capacity but allows for a smaller axis angle, usually not exceeding 30 °, and its performance is not as stable as the cage type under high-speed conditions. Ball fork universal couplings are commonly used in transmission applications with medium to low speeds and heavy loads, such as engineering machinery, agricultural machinery, and other equipment.

In addition to the three categories mentioned above, universal couplings also include various special structural forms such as three pin type, convex block type, ball joint plunger type, etc., each designed for specific application needs. For example, the three pin universal shaft coupling is particularly suitable for situations where the axis angle is large and axial movement is required, while the convex block type is more suitable for working conditions that require absorption of large impact loads. In practical applications, universal couplings can be classified into four levels based on the magnitude of the transmitted torque: heavy, medium, light, and small, corresponding to different industrial application scenarios.