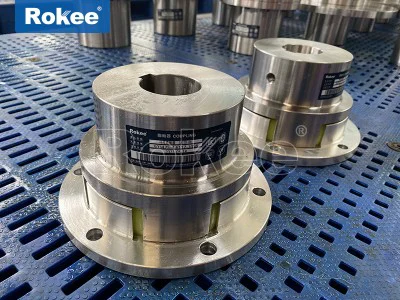

Jaw Type Couplings

Jaw type coupling is an elastic coupling widely used in mechanical transmission systems, and has become an important connecting component in the industrial field due to its unique structure and performance characteristics.

Compared with traditional rigid couplings, jaw type couplings achieve a certain degree of axial, radial, and angular deviation compensation through elastic elements, while also having shock absorption and buffering functions, which can effectively absorb vibration and impact loads in the transmission system. Its compact structure, easy installation, and simple maintenance make it an ideal choice for small and medium power transmission systems.

Jaw type couplings typically consist of three basic components:

Two metal wheels: usually made of high-quality alloy steel or stainless steel and precision machined. Each wheel hub has a shaft hole at one end (with keyway or clamping design) and evenly distributed claws at the other end (usually 6-8).

Elastic Spider: A star shaped component made of elastic material located between two wheel hubs, with its "arms" interlocked with the wheel hub claws. Common materials include polyurethane, nitrile rubber, Hytrel, etc.

According to application requirements, jaw type couplings have developed various structural variants:

Standard type: The most basic symmetrical structure, with two identical wheels

Flange type: One end is connected by a flange, suitable for specific installation requirements

Shaft sleeve type: with extended shaft sleeve, convenient for special installation occasions

Brake wheel type: Integrated brake wheel function, used in situations where braking is required

The jaw type coupling transmits torque between two metal wheels through an elastic spider. When the driving shaft rotates, the claws of the driving wheel hub compress the elastic spider, which then transmits the force to the claws of the driven wheel hub, thereby achieving power transmission. This structure allows for some elastic deformation during the transmission process, which can compensate for axis deviation.

Jaw type couplings can compensate for three basic types of deviations:

Axial deviation: ± 0.4-1.5mm (depending on specifications)

Radial deviation: 0.2-0.8mm

Angular deviation: generally not exceeding 1-2 degrees

Elastic spider is the core functional component of jaw type coupling, and its material properties directly affect the performance of the coupling:

Hardness: typically Shore A hardness of 60-95, affecting stiffness and damping characteristics

Temperature range: The working temperature range for different materials varies from -40 ° C to+120 ° C

Chemical resistance: Different elastomers have varying degrees of resistance to oil, water, chemicals, etc

Main performance indicators

Rated torque: ranging from a few Newton meters to several thousand Newton meters

Maximum speed: usually 3000-8000rpm, depending on specifications

Torsional stiffness: moderate stiffness, capable of effectively absorbing impacts

Axial stiffness: relatively high, limited axial displacement capability

Inertia: Low, suitable for quick start stop situations

The correct selection of jaw type couplings requires consideration of the following parameters:

Maximum torque of the transmission system (considering peak torque and sustained torque)

Speed range (including maximum speed and critical speed)

Shaft diameter size and connection method (keyway, clamping, etc.)

Environmental conditions (temperature, humidity, corrosive media, etc.)

Deviation compensation requirements (axial, radial, angular deviation)

Space limitations and installation methods

Selection calculation steps

Determine the application coefficient (based on load type and working conditions)

Calculate corrected torque=rated torque x application factor

Select the coupling specification so that its rated torque is equal to or greater than the corrected torque

Verify whether the parameters such as speed and deviation compensation meet the requirements

Correct installation steps

Clean the contact surface between the shaft and coupling

Check the fit tolerance between the shaft and the coupling hole (usually H7/js6)

Avoid using hammers for direct installation, it is recommended to use specialized installation tools

Ensure that the two axes are aligned within the allowable deviation range

Tighten all fastening bolts evenly to avoid unilateral stressroutine maintenance

Regularly check the wear of the elastic spider (recommended to check every 6 months)

Check if the fasteners are loose

Observe the vibration and noise changes during the operation of the coupling

Regular lubrication (required for some models)

Timely replace worn or aged elastomers

Jaw type couplings are widely used in various industrial fields, including but not limited to:

General industrial equipment

Pumps (centrifugal pumps, gear pumps, etc.)

Fans and blowers

compressor

Conveyor belt system

Mixing equipmentAutomated equipment

CNC machine tool

packaging machinery

Printing machinery

textile machinerySpecial applications

Food processing equipment (requires stainless steel material)

Pharmaceutical equipment (must comply with hygiene standards)

Ship equipment (requiring corrosion resistance)

Main advantages

High cost-effectiveness: more competitive in price compared to other flexible couplings

Easy maintenance: Replacement of elastomers requires no mobile devices

Buffer and shock absorption: effectively absorbs impact and vibration

No backlash: providing precise transmission performance

Electrical insulation: can isolate shaft current

Limitations of use

Limited compensation capability, not suitable for large deviation situations

The elastomer has aging issues and needs to be replaced regularly

Performance is limited in high temperature or corrosive environments

Not suitable for extremely high precision or ultra-high speed applications

Proper selection and use of jaw type couplings can significantly improve the reliability and service life of mechanical transmission systems.