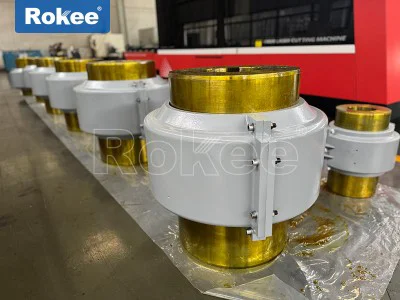

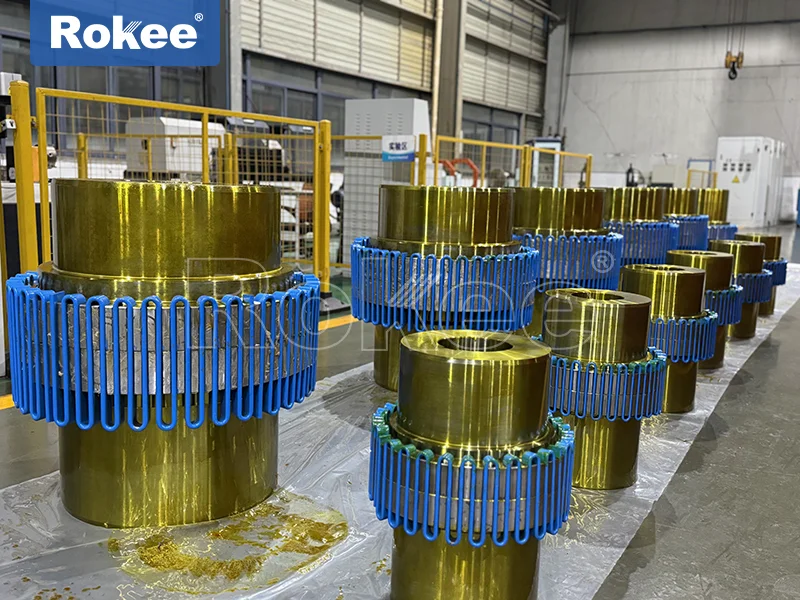

Flexible Snake Couplings

The flexible snake coupling is an advanced mechanical transmission component that achieves a perfect balance between power transmission and displacement compensation through a specially designed serpentine spring structure. This type of coupling mainly consists of two wheel hubs with toothed flanges and a metal spring band that is bent in a snake shape. The spring band is carefully installed in the tooth grooves of the two wheel hubs, forming a flexible and sturdy connection system.

When the driving shaft rotates, the teeth of the hub push the spring belt, which in turn drives the driven wheel to rotate. The unique design of the snake shaped spring enables it to compensate for various shaft deviations through the elastic deformation of the spring while transmitting torque. This structure can not only effectively transmit power, but also absorb impact loads, reduce vibration transmission, and protect connected equipment from damage.

The flexible snake coupling exhibits multiple outstanding performances in modern industrial applications:

Excellent displacement compensation capability:

Axial displacement compensation: ± 1-5mm (depending on the model)

Radial displacement compensation: 0.5-3mm

Angular deviation compensation: 1 ° -3 °

This multi-directional compensation capability enables it to adapt to various installation errors and dynamic offsets during operation.Efficient torque transmission:

Wide torque range, from a few Newton meters to tens of thousands of Newton meters

High torque density, small size yet capable of transmitting large torque

Zero backlash design ensures precise transmissionExcellent vibration damping performance:

The high damping characteristics of springs can absorb up to 30% of vibration energy

Significantly reduce transmission system noise (can reduce noise by 5-10 decibels)

Effectively suppress resonance phenomenonLong life design:

Made of high-quality alloy spring steel, with a fatigue life of millions of cycles

Wear free design, no lubrication required

Special coating treatment, strong corrosion resistance

flexible snake couplings are widely used in various industrial fields due to their excellent performance:

In the field of heavy industry:

Metallurgical equipment: rolling mill, straightening machine

Mining machinery: crushers, ball mills

Ship propulsion system: main propulsion shaft connectionEnergy industry:

Generator set: connection between turbine and generator

Wind power generation: transmission between the gearbox and the generator

Pump system: high-power water pump driveManufacturing equipment:

Machine tool industry: high-precision machining centers

Plastic machinery: extruders, injection molding machines

Paper Machinery: Large Roll Diameter Transmission SystemSpecial environmental applications:

Chemical industry: occasions requiring corrosion resistance

Ocean engineering: high salt spray environment

Military equipment: high reliability requirement system

To ensure optimal performance of the flexible snake coupling, professional installation and maintenance standards must be followed:

Precision installation process:

Using laser centering instrument to ensure axis centering accuracy ≤ 0.05mm

Use hydraulic tools to install the wheel hub and avoid hammering

Tighten the bolts in stages using a cross sequenceKey points of operation monitoring:

Regularly inspect the spring for cracks or permanent deformation

Monitor operating temperature, abnormal temperature rise may indicate problems

Pay attention to abnormal vibrations or noise changesPreventive maintenance strategy:

Check the alignment status every 2000 operating hours

Conduct a comprehensive inspection once a year

Establish vibration monitoring files to track performance changesFault diagnosis techniques:

Periodic vibration: usually indicates poor alignment

Random vibration: The spring may be damaged or loose

Abnormal temperature: Check for overload or lubrication contamination

As a key component of modern mechanical transmission systems, the flexible snake coupling's technological innovation will continue to promote the development of industrial equipment towards high efficiency, reliability, and intelligence. Choosing and applying this type of coupling correctly can significantly improve equipment performance and reduce maintenance costs, making it an indispensable transmission solution for modern engineers.