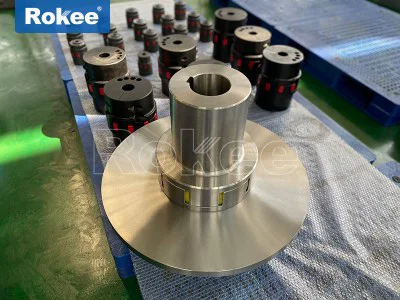

Flexible Claw Couplings

Flexible claw coupling is a key connecting component widely used in mechanical transmission systems. It achieves power transmission between two shafts through a special "claw" structure design, and has the ability to compensate for axial, radial, and angular deviations. This type of coupling consists of two clawed wheel hubs and an intermediate elastic element (usually a star or claw shaped elastic body), which absorbs and buffers vibrations and impacts during the transmission process through the deformation of the elastic element.

When the driving shaft rotates, it drives one claw shaped wheel hub to rotate, and transmits torque to another claw shaped wheel hub through elastic elements, thereby driving the driven shaft. Elastic components can compensate for various deviations between the two shafts through their flexible deformation while transmitting torque, ensuring smooth operation of the transmission system.

Core characteristics of flexible claw coupling

Excellent deviation compensation capability:

Axial deviation compensation: ± 0.5-3mm

Radial deviation compensation: 0.2-1.5mm

Angular deviation compensation: 1 ° -3 °Vibration damping characteristics: Elastic components can effectively absorb and attenuate vibrations in transmission systems, reduce noise levels (usually 5-15dB), and extend equipment service life.

Maintenance free design: Most flexible claw couplings adopt an integrated sealing structure, which does not require lubrication and significantly reduces maintenance costs.

High torque transmission efficiency: The transmission efficiency can reach 98-99.5%, with minimal energy loss.

Electrical insulation performance: Elastic components are usually made of non-conductive materials, which can provide good electrical insulation properties.

Typical structural types of flexible claw couplings

Standard Claw Coupling:

Symmetric Claw Design

Medium torque capacity

Suitable for general industrial applicationsHigh torque claw coupling:

Enhanced Claw Structure

Using high hardness alloy materials

Suitable for heavy machineryMicro claw coupling:

compact design

Small size (minimum up to Φ 10mm)

Used for precision instruments and small equipmentHigh temperature resistant special type:

Using special heat-resistant elastomers

The working temperature can reach over 150 ° C

Suitable for high temperature environments

Installation and maintenance of flexible claw coupling

Installation points:

The deviation of the two axis alignment should be controlled within the allowable range of the coupling

Avoid forced installation that may cause pre compression of the elastomer

Use specialized installation tools (such as hydraulic tensioners)Maintenance inspection items:

Regularly check the wear of elastic components

Monitor the operating temperature of the coupling (abnormal temperature rise may indicate a problem)

Check if the fasteners are looseCommon fault diagnosis:

Abnormal vibration: may be caused by poor alignment or damage to elastic components

Increased noise: usually indicates that the coupling has worn out

Decreased transmission efficiency: a sign of aging or wear of elastic components

Typical application areas of flexible claw couplings

Industrial automation:

Robot Joint Transmission

CNC machine feed systemEnergy equipment:

Wind turbine

Pumps and compressorsTransportation:

Ship propulsion system

Rail transit auxiliary equipmentSpecial Machinery:

Military equipment

Aerospace Ground Equipment

Flexible claw couplings are evolving towards higher performance and intelligence, becoming an indispensable key component in modern mechanical transmission systems. Choosing and using flexible claw couplings correctly can not only improve transmission efficiency, but also significantly extend the overall service life of equipment, creating greater value for enterprises.