Jaw Flexible Couplings

Jaw flexible coupling is a mechanical connection device that combines rigid transmission performance and moderate compensation capability, named after its unique "claw shaped" structure. This type of coupling plays a crucial role in industrial transmission systems by transmitting torque through interlocking claws and absorbing and buffering vibration impacts using elastic elements.

Compared with traditional rigid couplings, jaw flexible couplings have superior vibration reduction performance; Compared with pure elastic couplings, it can provide higher torque transmission capacity. This balancing characteristic makes it an ideal choice for many industrial applications, especially in situations where both transmission accuracy and system flexibility need to be considered simultaneously.

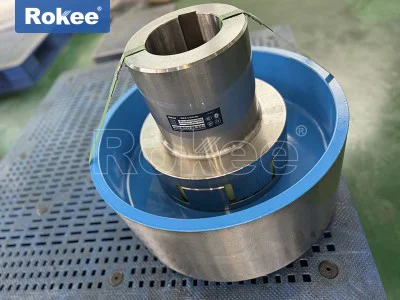

Jaw flexible couplings typically consist of the following core components:

Metal flange: usually made of high-strength cast iron, steel or aluminum alloy material, with precision machined claws on both sides

Elastic element: a rubber, polyurethane, or nylon material cushioning component placed between the claws

Connecting bolt: used to fix the two halves of the coupling and apply pre tension force

Protective cover (optional): protects the internal structure from environmental influences

The working principle of claw coupling is based on the principle of elastic deformation:

Torque transmission: The rotation of the active end pushes the elastic body through the convex claw, and the elastic body then transmits the force to the convex claw of the passive end

Vibration absorption: Elastic bodies deform when subjected to force, absorbing and damping system vibrations

Deviation compensation: The deformable characteristics of elastomers allow for a certain degree of axial, radial, and angular deviation

There are various variants of the convex claw design for modern claw couplings:

Straight claw type: basic form, easy to manufacture but limited compensation capability

Curve claw type: progressive contact, smoother transmission

Multi claw design: increase the number of contact points to improve torque capacity

Asymmetric Claw Type: Optimizing Load Distribution for Specific Operating Conditions

Jaw flexible couplings have the following significant advantages:

Excellent vibration reduction performance: can reduce system vibration by 40-60%

Good deviation compensation capability:

Axial deviation: ± 0.5-3mm

Radial deviation: 0.2-1.5mm

Angular deviation: 1 ° -3 °No backlash transmission: maintaining high transmission accuracy

Overload protection: The elastic body will be damaged first when overloaded, protecting valuable equipment

Maintenance free design: Most models do not require lubrication

Jaw flexible couplings are widely used in:

Pump equipment: centrifugal pump, plunger pump, vacuum pump

Compressor system: screw and reciprocating compressors

Power generation equipment: diesel generator sets, small steam turbines

Material conveying: conveyor belt, elevator, mixing equipment

Machine tool industry: CNC machine tool feed system

The basic maintenance content includes:

Visual inspection: Elastic cracking and wear condition

Vibration monitoring: Regularly measure changes in vibration values

Temperature check: Abnormal temperature rise may indicate a problem

Bolt inspection: Ensure proper pre tightening force

As a key component in industrial transmission systems, the correct selection and use of jaw flexible couplings directly affect the operational efficiency and reliability of the entire equipment. With the advancement of materials science and manufacturing technology, modern claw couplings have developed into high-performance and long-life transmission solutions. Through scientific selection and reasonable maintenance, jaw flexible couplings can provide reliable and efficient power transmission solutions for various industrial transmission systems.