Multi Jaw Couplings

Multi jaw coupling is a flexible coupling widely used in mechanical transmission systems, occupying an important position in the industrial field with its unique structural design and excellent transmission performance. This type of coupling usually consists of two half couplings with multi claw structures and an elastic element, which achieves power transmission through the meshing of claw teeth and elastic body.

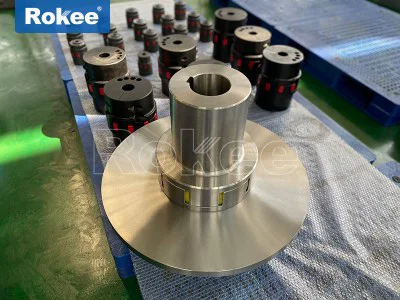

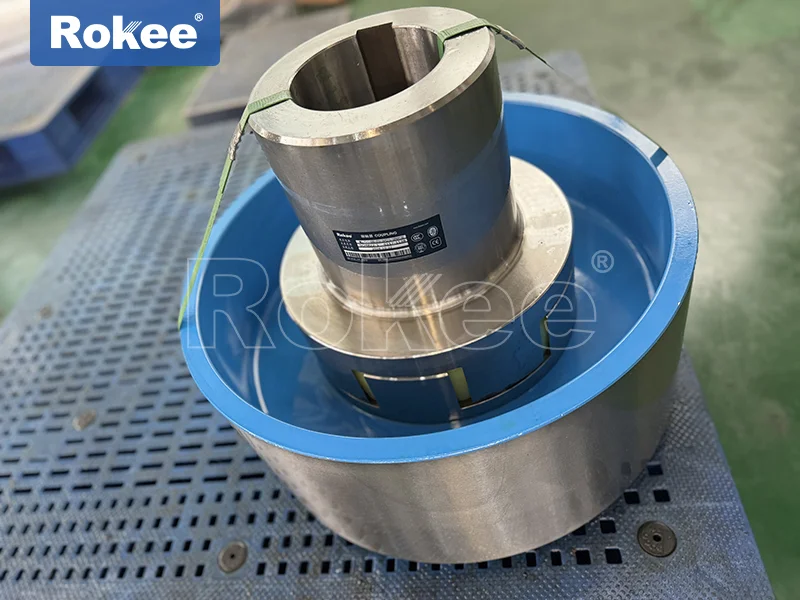

The typical structure of a multi jaw coupling includes:

Two metal half couplings: usually made of high-strength alloy steel, each half coupling end face is machined with multiple claws (usually 6-12)

Elastic element: located between two half couplings, mostly made of elastic materials such as polyurethane, rubber, or nylon

Tightening components: including bolts, nuts, etc., used to fix the coupling on the shaft

Multi jaw couplings achieve power transmission through the mutual meshing of claw teeth and elastic bodies. When the driving shaft rotates, it drives one half of the coupling to rotate, and its claws transmit torque to the other half of the coupling by squeezing the elastic body, thereby driving the driven shaft to rotate. Elastic bodies not only transmit torque during this process, but also play a role in buffering, damping, and compensating for deviations.

The torque transmission process can be divided into three stages:

Initial stage: The claw teeth begin to contact the elastic body, resulting in initial deformation

Load transmission stage: The elastic body deforms under the pressure of the claw teeth, effectively transmitting torque

Extreme stage: When the maximum design torque is reached, the deformation of the elastic body reaches its limit

Multi jaw couplings have multiple unique advantages compared to other types of couplings:

Excellent shock absorption performance: The elastic material effectively absorbs and dampens vibrations, reducing transmission system noise

Good deviation compensation capability: can simultaneously compensate for radial, angular, and axial deviations

Maintenance free design: No lubrication required, reducing maintenance costs

Overload protection function: When the torque exceeds the limit, the elastic body can slip, protecting the safety of the equipment

Easy installation: usually does not require special tools, reducing installation difficulty

Classified by type of elastomer

Polyurethane type: with high elasticity, wear resistance, and oil resistance, suitable for most industrial applications

Rubber type: Excellent shock absorption performance, suitable for high vibration environments

Nylon type: high mechanical strength, suitable for heavy-duty applications

Composite material type: combining the advantages of multiple materials to meet the needs of special working conditions

Classified by structural form

Standard type: Universal design, balancing various performance aspects

Flange type: with flange connection, easy to install and disassemble

Shaft sleeve type: directly sleeved on the shaft, compact structure

Quick disassembly type: designed with a quick disassembly mechanism for easy maintenance

Special purpose design

Explosion proof type: used in flammable and explosive environments

Corrosion resistant type: suitable for corrosive environments such as chemical engineering

Food grade: Compliant with food safety standards, used for food processing machinery

High precision type: used for precision transmission systems, such as machine tool spindles

The wide application scenarios of multi jaw couplings include:

Industrial machinery

Pump equipment: centrifugal pump, plunger pump, etc

Fan system: industrial fans, ventilation equipment

Compressors: air compressors, refrigeration compressors

Conveyor machinery: belt conveyor, chain conveyorMachine Tool and Automation

CNC machine feed system

Robot Joint Transmission

Automated production line transmission deviceSpecial Equipment

Ship propulsion system

generator set

Engineering machinery transmissionEmerging field

New energy equipment (wind power, solar tracking system)

Electric vehicle transmission system

Precision instruments and meters

Multi jaw couplings will continue to play an important role in the field of mechanical transmission, and their performance and application scope will continue to expand, providing more reliable and efficient transmission solutions for various mechanical systems.