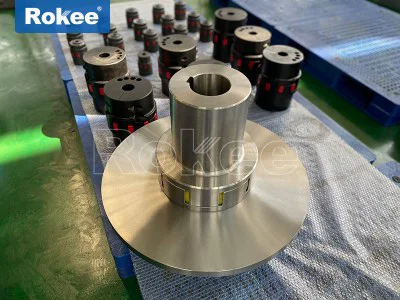

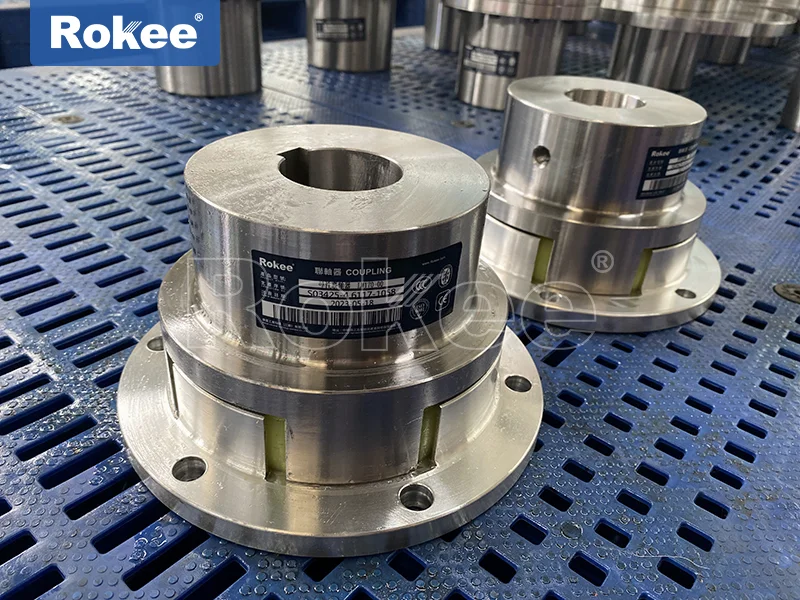

Claw Type Flexible Couplings

Claw type flexible coupling is a widely used type of elastic coupling in mechanical transmission systems. It connects shafts through a special "claw" design and has the ability to compensate for axial, radial, and angular deviations. This type of coupling is widely used in various industrial equipment due to its simple structure, easy installation, and low maintenance cost.

Compared with traditional rigid couplings, the most significant feature of claw type flexible couplings is that they can absorb and buffer vibrations and impacts caused by misalignment while transmitting torque, protecting other components in the transmission system from damage. Its unique flexible component design makes it perform well in medium torque transmission scenarios, especially suitable for working environments that require some elastic compensation.

A typical claw type flexible coupling consists of the following key components:

Metal wheel hub (claw plate): usually made of cast iron, steel or aluminum alloy material, with interlocking "claw" shaped structures on both sides, it is the main component for transmitting torque

Elastic element (buffer block): located between the two wheel hub teeth, mostly made of polymer materials such as polyurethane, rubber, or nylon, providing flexibility and cushioning effect

Connecting bolts and nuts: used to fix the two halves of the coupling and apply preload force

Protective cover (optional): Some models are equipped with protective covers to prevent foreign objects from entering and ensure safe operation

The core technology of claw coupling lies in its claw shaped meshing structure. Usually, there are 6-12 evenly distributed claw teeth on each wheel hub, which present a special arc-shaped or trapezoidal profile to ensure uniform stress distribution when transmitting torque. The claws of the two halves of the coupling are arranged in a staggered manner, and a non rigid connection is achieved through an elastic element in the middle.

This design allows for the existence of:

Axial displacement compensation: ± 0.5-3mm

Radial deviation compensation: 0.2-1.5mm

Angular deviation compensation: 0.5 ° -3 °

The material properties of the buffer block, as the core flexible component of the claw coupling, directly affect the performance of the coupling

Polyurethane (PU): The most common material with good wear resistance, tear resistance, and moderate elastic modulus, working temperature range of -30 ℃ to+80 ℃

Nitrile rubber (NBR): Good oil resistance, suitable for occasions with lubricating oil environment

Hytrel (polyester elastomer): High strength, fatigue resistant, suitable for high-speed applications

Nylon (PA): High rigidity, suitable for situations requiring high torsional stiffness

The elastic elements of different materials endow the coupling with different stiffness characteristics, and users can choose the appropriate type according to specific working conditions.

Claw type flexible couplings transmit torque through the compression deformation of elastic elements. When the driving shaft rotates, the claws of the driving hub push the elastic element, which then transmits the force to the claws of the driven hub, thereby achieving torque transmission. During this process, the elastic element is always in a compressed state rather than a shear state, which allows the claw coupling to withstand larger impact loads.

The ability of claw couplings to compensate for shaft system deviations comes from the deformability of elastic elements and the design of clearances between claw teeth

Axial compensation: When there is axial displacement between the two axes, the elastic element can compress or extend axially between the claw teeth

Radial compensation: The radial deformation ability of elastic elements allows for a certain center deviation between the two axes

Angular compensation: The change in angle between the claw teeth causes uneven compression of the elastic element, achieving absorption of angular deviation

It is worth noting that any form of deviation can cause additional stress on the elastic element, so in practical applications, the misalignment should be minimized as much as possible to extend the life of the coupling.

The elastic elements of claw couplings have significant damping characteristics, which can effectively absorb and attenuate vibrations transmitted from the prime mover (such as a motor) or load end. This feature is particularly suitable for:

Suppress torsional vibration during motor start-up

Reduce impact loads in gearboxes or transmission chains

Reduce the noise level of the entire transmission system

When choosing a claw type flexible coupling, the following main technical parameters need to be considered:

Rated torque Tn: The maximum torque that the coupling can continuously transmit (N · m)

Maximum torque Tk: the peak torque that can be sustained in the short term (usually about 2-3 times the rated torque)

Allowable speed n: the maximum working speed (rpm) related to the size and balance level of the coupling

Torsional stiffness: reflects the ability of the coupling to resist torsional deformation (N · m/rad)

Moment of inertia: an important parameter affecting the acceleration performance of the system (kg · m ²)

Working temperature range: depends on the elastic element material (usually -30 ℃ to+80 ℃)

The key to ensuring the long-term reliable operation of the coupling lies in correct installation:

Cleaning inspection: Clean the shaft end and coupling inner hole, check for damage

Centering adjustment: use a dial indicator or a laser centering instrument for accurate centering, and control the deviation within the allowable range

Assembly of wheel hub: Use appropriate methods (hot installation or hydraulic tools) to install the wheel hub onto the shaft

Install elastic components: Install buffer blocks according to the marked positions to ensure uniform distribution

Connect the two halves of the coupling: alternately and evenly tighten the connecting bolts to the specified torque

Final inspection: manually rotate to check for any jamming, and perform dynamic balancing if necessary

Although claw couplings are low maintenance products, regular inspections are still essential:

Visual inspection: Check the elastic components monthly for cracks, permanent deformation, or wear

Bolt inspection: Check the tightening status of bolts every 3-6 months to prevent loosening

Re check the alignment after major equipment repairs or abnormal vibrations

Lubrication: Some models require regular lubrication of the claw tooth contact surface (using specified grease)

Claw type flexible couplings are widely used in various industrial equipment:

Pump equipment: centrifugal pump, plunger pump, vacuum pump, etc

Fan system: centrifugal fan, axial flow fan, blower

Compressor: screw type, reciprocating air compressor

Conveyor machinery: conveyor belts, elevators, mixing equipment

Claw type flexible couplings, as an economical and practical mechanical transmission component, occupy an important position in the industrial field due to their excellent comprehensive performance. With the application of new materials and technologies, their performance will be further improved and their application scope will continue to expand. Proper selection, installation, and maintenance of claw type flexible couplings can significantly improve the reliability and service life of mechanical transmission systems, creating greater value for enterprises.