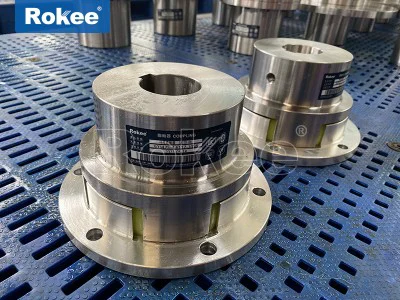

Jaw Flex Couplings

Jaw flex coupling is a mechanical connection device widely used in industrial transmission systems. It achieves power transmission between two shafts through a special claw shaped structure, while allowing for a certain degree of axial, radial, and angular deviation. This type of coupling is named after its unique "claw tooth meshing" design and plays a key role in various mechanical transmission systems.

Compared with traditional rigid couplings, jaw flex couplings have significant advantages: they can effectively compensate for installation errors, absorb vibrations and impacts, and protect connected equipment from excessive loads. At the same time, its compact structure, high torque transmission, and no need for lubrication make it widely used in many industrial fields.

Jaw flex coupling mainly consists of the following parts:

Two half couplings: installed on the drive shaft and driven shaft respectively, usually forged from high-strength alloy steel

Elastic element: located between the two halves of the coupling, common materials include polyurethane, rubber, nylon, etc

Claw tooth structure: Multiple protruding claw teeth machined on the end face of the half coupling, usually distributed uniformly in a radial pattern

Connecting bolt: used to fix the two halves of the coupling, some designs adopt maintenance free clamping connection method

The jaw flex coupling transmits torque through the meshing of claw teeth on the two halves of the coupling, and the elastic element in the middle allows for deviation in three directions while transmitting power:

Axial deviation compensation: The compression deformation of the elastic element allows for a small amount of axial displacement between the two axes

Radial deviation compensation: The clearance between the claw teeth and the elastic element allows for radial deviation

Angular deviation compensation: The bending deformation of elastic elements allows for small angles of misalignment between the two axes

When torque is transmitted, the claw teeth on the driving side transmit force to the claw teeth on the driven side by squeezing the elastic element. The elastic element absorbs vibration and impact energy during this process, protecting the connected equipment.

Classified by elastic components

Polyurethane Jaw Coupling:

The elastomer is made of polyurethane material

High elasticity, excellent shock absorption performance

Oil resistant, aging resistant, long service life

The working temperature range is usually between -30 ℃ and+80 ℃Rubber Jaw Coupling:

Using natural or synthetic rubber as elastic components

Excellent damping characteristics and good vibration absorption effect

Low cost, but poor temperature and oil resistance

Suitable for low-speed and high torque applicationsNylon Jaw Coupling:

Using engineering nylon as elastic material

High mechanical strength and good wear resistance

Suitable for high-speed applications

But the elasticity is relatively poor and the compensation ability is limited

Classified by structural design

Standard Jaw Coupling:

The most common symmetrical design

The number and shape of claws on both sides are the same

No need to distinguish directions during installationAsymmetric Jaw Coupling:

The design of the claws on both sides is different

Can achieve special torque transmission characteristics

Commonly used for transmission systems with special requirementsJaw Coupling with intermediate:

Add intermediate connectors

Allow for greater deviation compensation

Suitable for long-distance axis connections

Key performance parameters

Rated torque: the maximum torque value that the coupling can continuously transmit

Maximum torque: The peak torque that can be sustained in a short period of time, usually 2-3 times the rated torque

Speed range: The maximum allowable working speed, which is related to the size and balance level of the coupling

Deviation compensation capability:

Axial direction: usually 0.5-5mm

Radial: usually 0.2-2mm

Angular direction: usually 0.5 ° -3 °Moment of inertia: affecting the dynamic response characteristics of the system

Working temperature range: depends on the elastic element material

Selection considerations

Load characteristics:

Constant load or variable load

Is there any impact or vibration

Starting frequency and braking requirementsEnvironmental conditions:

ambient temperature

Are there any oil stains, chemicals, or dust present

Humidity situationSpace limitations:

Installation space size

Do you need easy disassembly

Axial movement demandEconomy:

Initial cost

maintenance cost

Expected service life

Correct installation steps

Preparation work:

Check the size matching of the shaft and coupling

Clean the shaft end and coupling inner hole

Prepare suitable installation toolsInstall the half coupling:

Use specialized tools to press the half coupling onto the shaft

Ensure that the specified axial positioning position is achieved

Check radial and axial runoutAlignment correction:

Use a dial gauge or laser centering device for precise centering

Ensure that the deviation is within the allowable range

Pay special attention to the impact of angular deviationFinal fixation:

Tighten the connecting bolts according to the prescribed torque

Check if all fasteners are secure

Manually rotate to check for interference

Key points of daily maintenance

Regular inspection items:

Wear condition of elastic components

Is there any abnormal noise or vibration

Is the connecting bolt loose

Seal integrity (if applicable)Suggested maintenance cycle:

Monthly: Visual inspection of appearance status

Quarterly: Check the alignment and bolt tightening status

Every year: comprehensive dismantling and inspection, replacement of worn partsCommon problem handling:

Abnormal vibration: Check the alignment and replace worn elastic components

Overheating: Check if the load exceeds the standard and lubrication status (if lubrication is required)

Noise: Check the coordination status of each component and eliminate foreign object interference

Main industrial applications

Pump equipment:

Centrifugal pumps, plunger pumps, etc

Compensation for installation deviation between pump and motor

Vibration caused by absorbing fluid pulsationFan system:

Centrifugal fan, axial flow fan

Reduce vibration transmission caused by rotor imbalance

Allow axial displacement caused by thermal expansionCompressor:

Reciprocating and screw compressors

Buffer the impact load of piston movement

Protect the motor from torsional vibrationConveyor machinery:

Belt conveyor, chain conveyor

Difficulty in compensating for the alignment of the long axis system

Adapt to deviations caused by foundation settlement

Jaw flex couplings as key components in the field of mechanical transmission, continue to innovate and develop with the advancement of industrial technology. In the future, higher performance and more intelligent jaw couplings will play a more important role in industry and intelligent manufacturing, providing more reliable and efficient connection solutions for various rotating equipment.