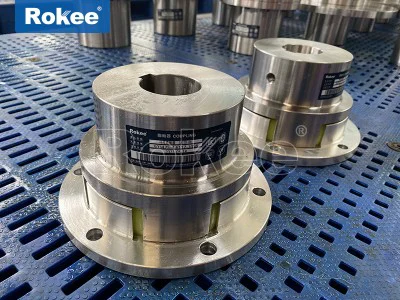

Plum Blossom Couplings

Plum blossom coupling is a widely used type of elastic coupling, named after its internal elastic body shape resembling a plum blossom. This type of coupling is connected between two shafts through a "plum blossom shaped" elastic element in the middle, which can effectively compensate for axial, radial, and angular deviations within a certain range, while also having the ability to buffer and absorb shock.

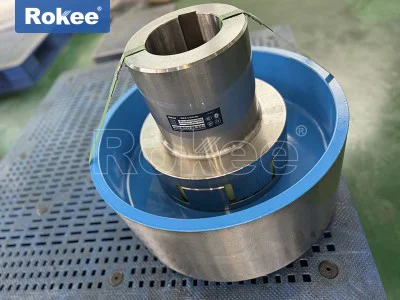

The plum blossom coupling consists of three main parts:

Two metal half couplings: usually made of high-quality alloy steel or cast iron, surface treated and precision machined, one side connected to the driving shaft and the other side connected to the driven shaft

Plum shaped elastomer: As the core component, it is generally made of polymer materials such as polyurethane, rubber, or nylon, with specific hardness and elasticity

Fastener system: including bolts, nuts, etc., to ensure reliable connection between the coupling and the shaft end

The performance of the plum blossom coupling largely depends on the material properties of the elastomer

Polyurethane elastomer: Wide hardness range, good wear resistance, strong oil resistance, suitable for most industrial environments

Rubber elastomer: excellent shock absorption performance, but relatively poor oil and high temperature resistance

Nylon elastomer: high mechanical strength, good high temperature resistance, but relatively low elasticity

Different colors of elastomers usually represent different hardness and material properties, and users can choose the appropriate type according to specific working conditions.

The plum blossom coupling achieves torque transmission and deviation compensation through the deformation of the elastic body:

The rotation of the active shaft drives the rotation of the half coupling

Convex tooth squeezing elastic body of half coupling

Elastic deformation transfers force to the other half of the coupling

The driven shaft rotates to complete the power transmission

Main performance characteristics

Deviation compensation capability:

Axial deviation: usually 0.5-3mm

Radial deviation: usually 0.2-1.5mm

Angular deviation: usually 1 ° -3 °Shock absorption and buffering: The elastic material can absorb vibration energy and reduce the impact of the transmission system

Electrical insulation: Non metallic elastomers provide electrical isolation between shafts

No lubrication maintenance: No need to regularly add lubricating oil, reducing maintenance costs

Overload protection: In extreme cases, the elastic body can break, protecting equipment safety

Key parameters

Rated torque: The maximum torque (N · m) that the coupling can transmit continuously during operation

Maximum torque: The maximum torque allowed for short-term overload (usually 2-3 times the rated value)

Maximum speed: related to coupling size and balance level (rpm)

Shaft hole form: cylindrical hole, conical hole, keyway hole, etc

Shaft hole diameter range: usually 6-100mm, special models can reach even larger diameters

Correct installation steps

Cleaning inspection: Ensure that the contact surface between the shaft end and the coupling is clean and undamaged

Centering adjustment: use a dial indicator or a laser centering instrument to ensure that the deviation of the two axes is within the allowable range

Assembly sequence:

First, install the half coupling onto the shaft (using hot installation or hydraulic tools)

Install the elastomer to ensure complete insertion into the tooth slot

Connect the other half of the couplingTightening inspection: Confirm that all bolts are evenly tightened in diagonal order

Manual testing: Rotate the coupling to check for any abnormal resistance

Maintenance suggestions

Regular inspection: Check the wear of the elastic body every 3-6 months

Replacement standard: When the elastic body cracks, undergoes permanent deformation, or changes in hardness by more than 15%, it should be replaced

Re check the alignment of the shaft after major maintenance or relocation of the equipment

Cleaning and protection: Avoid direct contact between oil, grease, and chemicals and the elastomer

Spare parts reserve: Maintain an appropriate quantity of elastic spare parts for timely replacement

Typical application scenarios

General industrial equipment: pumps, fans, compressors, mixers, etc

Automation equipment: robotic arms, conveyor systems, packaging machinery

Power generation equipment: small generators, wind power yaw systems

Transportation equipment: auxiliary transmission system for rail vehicles

Machine Tool Industry: Feed System for Small and Medium sized CNC Machine Tools

Industry application cases

Food processing industry: Stainless steel plum blossom couplings are used in filling production lines to meet hygiene standards

Pharmaceutical equipment: using special elastomers, cleaning agents, and high-temperature sterilization

Marine Engineering: Corrosion resistant Coating Couplings for Marine Pump Systems

Mining machinery: reinforced design for heavy-duty equipment such as vibrating screens

As an important component of modern mechanical transmission systems, the reasonable selection and use of plum blossom couplings have a significant impact on the reliability, efficiency, and service life of equipment operation. With the advancement of materials science and manufacturing technology, Meihua couplings will continue to leverage their unique advantages in a wider range of fields.