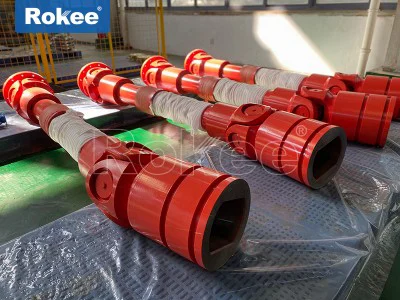

Universal Shafts

As a key component in mechanical transmission systems, universal shafts play an irreplaceable role in modern industrial equipment. It can achieve efficient transmission of torque and motion when the two axis lines do not coincide and there is an angle, solving the problem of angle deviation that traditional rigid couplings cannot cope with.

Universal shaft is a special type of flexible joint, whose core function is to connect two shafts (active shaft and passive shaft) on different axes, enabling them to achieve continuous rotation and reliably transmit torque and rotational motion in the presence of axis angles. This type of coupling overcomes the limitations of traditional couplings that require high accuracy in shaft alignment through its unique mechanism design, providing greater layout flexibility for mechanical transmission systems.

From the perspective of mechanical principles, the core feature of universal couplings is their ability to provide significant angular compensation. The allowable angle range between the two axes of universal couplings with different structural forms is usually between 5 ° and 45 °, depending on the type and design of the coupling. For example, the cross axis universal shaft generally allows an axis angle of 15 ° -45 °, while the ball cage universal shaft can achieve greater angle compensation capability. This angle compensation capability enables universal couplings to adapt to various complex installation conditions and operating conditions, including axis deviations caused by installation errors, foundation settlement, shaft deformation, and other factors.

In addition to angle compensation capability, universal couplings also have two major advantages: compact structure and high transmission efficiency. The compact structural design enables efficient power transmission within a limited space, while a transmission efficiency of up to 98% -99% ensures minimal energy loss during transmission. These characteristics collectively make universal couplings an indispensable transmission component in many industrial applications, especially in situations where high torque transmission is required and there is axis deviation.

The cross axis universal shaft is the most common and widely used type, with its core components including two fork joints and a cross axis assembly. The cross axis is connected to the fork head through needle roller bearings, allowing for angular deflection in two planes. This structure is simple and reliable, with relatively low manufacturing costs and the ability to transmit large torque, making it particularly suitable for heavy industrial equipment such as metallurgy, mining, and lifting and transportation. Cross axis universal couplings can be divided into various forms such as SWC type (integral fork head), SWP type (partial bearing seat), and SWZ type (integral bearing seat), produced according to JB/T series industry standards to meet different load and working condition requirements. In practical applications, in order to eliminate speed fluctuations in single cross shaft coupling transmission, a double coupling form is usually adopted. Two single cross shaft couplings are connected in series through an intermediate shaft, and the principles of "the fork heads at both ends of the intermediate shaft are in the same plane" and "the angle between the input and output shafts and the intermediate shaft is equal" are followed to achieve constant speed transmission.

The ball cage universal shaft represents a more advanced technology, which adopts a precision structure composed of a spherical shell, star shaped sleeve, and steel ball. The steel ball is fixed between the inner and outer raceways by a cage, and constant speed transmission is achieved through precise geometric design. The biggest advantage of ball cage couplings is their constant speed and greater angle compensation capability (up to 40 °), as well as smooth operation and low noise, making them particularly suitable for high-speed precision transmission applications. The front wheel drive system of automobiles commonly uses ball cage universal shafts, effectively solving the complex angle changes caused by steering and suspension movements. In the industrial field, ball cage couplings are gradually replacing traditional cross axis products and are applied to equipment such as machine tools and robots that require high transmission accuracy.

The ball fork cardan shaft is another common type, with a structure similar to the cage type but typically using four or six steel balls to transmit torque instead of a cage structure. Ball fork couplings are relatively simple to manufacture and have lower costs, but their load-bearing capacity and angle compensation performance are slightly inferior to cage couplings. This type of coupling is commonly used in low to medium precision transmission systems such as agricultural machinery and engineering vehicles. It is worth noting that the ball fork coupling has slight speed fluctuations during transmission and is not suitable for situations that require strict constant speed transmission.

Other special types of universal couplings include:

Ball joint universal shaft: adopting a spherical joint structure, the overall strength is increased by 37%, and the radial bearing capacity is increased by 52%. It is suitable for situations with large radial displacement

Steel ball universal shaft: With the characteristic of self determined rotation center, high transmission efficiency and good dynamic balance accuracy, it is specially used for precision transmission systems such as diesel engine common rail oil pump

Triple wishbone universal shaft: angle compensation is achieved through three articulated rods, suitable for situations with excessive torque transmission

Convex block universal shaft: simple structure, easy maintenance, commonly used in low-speed heavy-duty equipment

According to the magnitude of the transmitted torque, universal couplings can be divided into four levels: heavy, medium, light, and small, meeting different needs from micro instruments to large industrial equipment. In terms of material selection, 45 steel, 40Cr alloy steel, and cast iron are commonly used materials, and stainless steel or surface special treatment processes can also be used for special working conditions.

The correct selection and configuration of universal couplings are crucial for ensuring the reliable operation of the transmission system, which requires comprehensive consideration of multiple technical parameters and operating conditions. The selection of universal shaft is a systematic project that involves multiple factors such as torque calculation, speed determination, and angle compensation requirements.

Angle compensation capability is a characteristic parameter of universal couplings, and the allowable range of axis angles varies significantly among different types of couplings. When selecting, it should be ensured that the maximum allowable angle of the coupling is greater than the maximum possible angle in practical applications, and appropriate safety margins should be retained. During actual installation, the axis angle should be minimized as much as possible (ideally not exceeding 3 °), as operating at large angles can significantly reduce bearing life, increase vibration, and energy consumption. For situations that require large angle compensation, a double joint universal shaft structure can be used to achieve constant speed transmission through reasonable configuration.