Flexible Drive Gear Couplings

In the context of rapid development of intelligent manufacturing today, flexible drive gear coupling as key components of mechanical transmission systems, are playing an increasingly important role. This type of coupling achieves flexible connection during the transmission process through its unique design and material application, effectively solving the limitations of traditional rigid couplings in vibration absorption, deviation compensation, and noise control.

Flexible drive gear couplings represent an important development direction of modern transmission technology, cleverly integrating the precision of gear transmission with the adaptability of flexible connections. In the intricate symphony of automated production lines, the power transmission system is like a key melody in a symphony, and the coupling is the core element that ensures the accuracy of each note. Once the coupling performance is poor, problems such as increased system vibration, decreased positioning accuracy, and shortened equipment service life will arise one after another, seriously affecting production efficiency and product quality.

Compared with traditional couplings, the biggest advantage of flexible gear couplings is their excellent deviation compensation capability. It can effectively absorb and compensate for installation deviations in axial, radial, and angular directions, protecting the transmission system from additional stress caused by misalignment. For example, in high-speed servo systems, the small backlash of the coupling can lead to accumulated position errors, while high-quality flexible gear couplings adopt a pre tensioned design. By optimizing the contact stress distribution, true zero backlash transmission can be achieved, and the angular compensation accuracy can reach ± 0.05 °, ensuring synchronization accuracy during multi axis linkage.

Flexible drive gear couplings also have vibration damping characteristics, which can absorb and reduce vibrations and impacts transmitted from the motor or load end, protecting precision transmission components. In the intelligent manufacturing environment, with the development trend of high-speed and precision equipment, this damping function has become increasingly important and has become one of the key factors in ensuring product quality consistency.

Flexible drive gear couplings can be divided into multiple types based on their structural design and material applications, each with its unique performance characteristics and applicable scenarios. Understanding these types and their differences is crucial for proper selection and optimization of transmission system performance.

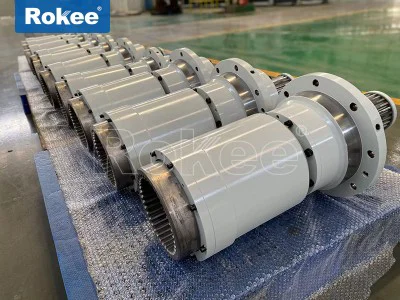

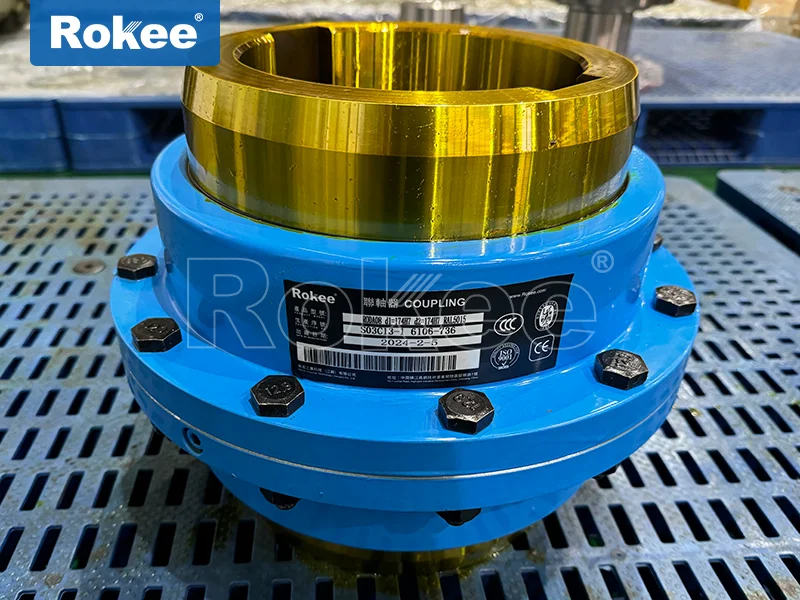

Elastic gear coupling is one of the most common types in industrial applications, which adopts a design combining metal gears and elastic components. The typical representative of this type of coupling is the drum shaped gear coupling, which is characterized by the spherical shape of the tooth top of the outer gear shaft sleeve, and can achieve significant angular and radial deviation compensation when meshing with the inner gear ring. For example, the GIICL drum gear coupling has a torque range of 20-40000 Nm, allowing for angular deviation of 1.5 ° and radial deviation of 0.2-6.3mm, making it particularly suitable for heavy machinery and mining equipment. Elastic components are usually made of polyurethane or rubber materials, which not only ensure the accuracy of transmission, but also absorb impact and vibration.

Choosing a suitable Flexible drive gear coupling is an engineering and technical decision that requires comprehensive consideration of multiple factors. The correct selection not only ensures the efficient and stable operation of the transmission system, but also extends the service life of the equipment and reduces maintenance costs. In the field of intelligent manufacturing, with the development of precision and high-speed equipment, the selection of couplings has become more critical.

Torque characteristics are the primary consideration factor in selection. Engineers need to accurately calculate the rated torque, peak torque, and possible impact torque of the system, and select couplings with sufficient safety margins.

The deviation compensation capability is directly related to the adaptability of the coupling to system installation errors. Including axial deviation, radial deviation, and angular deviation. In complex transmission systems with long axis systems or multiple support points, cumulative errors may be significant, and it is necessary to choose drum tooth or double diaphragm couplings with strong compensation capabilities. It is particularly noteworthy that certain high-precision applications, such as semiconductor equipment, have extremely strict control over axial movement and require the use of special couplings with limit structures.

Dynamic performance parameters are particularly important in high-speed precision transmissions. This includes critical speed (to avoid resonance), torsional stiffness (affecting positioning accuracy), and moment of inertia (affecting acceleration performance).