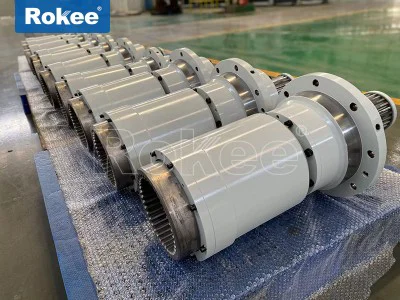

Brake Drum Geared Couplings

The brake drum geared coupling as a special mechanical transmission component, plays a crucial role in modern industrial equipment. It perfectly combines the efficient transmission characteristics of gear couplings with the safety control function of braking devices, and is widely used in heavy-duty mechanical systems that require precise control. This type of coupling can not only transmit huge torque, but also effectively compensate for shaft deviation, while achieving rapid stop or position maintenance of the equipment through an integrated braking mechanism. From metallurgical rolling mills to mining lifting equipment, from port cranes to heavy engineering machinery, brake drum geared couplings have won the favor of engineers for their excellent performance and reliability.

The structural design of the brake drum geared coupling cleverly integrates gear transmission and braking functions, and its core components can be divided into three main parts: the gear coupling body, the brake drum component, and the connecting support structure. This carefully designed combination not only meets the basic needs of power transmission, but also integrates brake control functions, greatly simplifying the overall layout of the mechanical system.

The main body of the gear coupling adopts a drum shaped tooth design, which is the key difference from ordinary straight tooth couplings. The main body is composed of an inner gear ring and an outer gear shaft sleeve, where the outer teeth are not simply straight teeth, but are processed into a drum shape - that is, the tooth surface is raised in a circular arc shape, similar to a barrel or spherical shape. The design of this drum shaped gear allows the coupling to obtain greater angular compensation capability. Theoretically, the allowable angular displacement of the drum shaped gear coupling can reach 1 ° 30 ′, which is about 50% higher than that of the traditional spur gear coupling. The internal gear ring is usually integrated with the half coupling and connected to the equipment shaft flange through high-strength bolts. The special contour of the drum shaped teeth enables the contact point of the gear to automatically adjust with the axis deviation during meshing, avoiding the edge contact problem that occurs in straight tooth couplings during angular deviation, significantly improving the contact area of the tooth surface and the uniformity of load distribution.

The brake drum component is another core part of this type of coupling, usually located on the outer periphery of the coupling. The brake drum is generally made of high-strength cast iron or alloy steel, and its inner circular surface is precisely matched with the outer circle of the gear coupling body. The outer circular surface is processed as a very smooth and flat brake friction surface to ensure that the friction material can uniformly contact during braking. The diameter and width of the brake drum are designed according to the required braking torque, and the diameter of the brake drum for large equipment can reach more than 1 meter. One side of the brake drum is usually designed with heat dissipation ribs or ventilation slots to accelerate the dissipation of heat generated during braking. Brake calipers or brake bands are installed around the periphery of the brake drum, which are driven by hydraulic, pneumatic, or electromagnetic means to press the friction plate against the surface of the brake drum, thereby generating braking torque to slow down or stop the system.

The connecting support structure includes auxiliary components such as bearing seats, sealing systems, lubrication pipelines, and protective covers. The bearing seat is used to support the rotating parts of the coupling and withstand radial loads; The sealing system adopts a labyrinth seal or rubber oil seal to prevent lubricant leakage and external pollutants from entering; The lubrication pipeline is responsible for guiding the lubricating oil to the gear meshing area, and some high-end models are also equipped with automatic lubrication systems; The protective cover plays a role in safety protection and preventing foreign objects from getting involved. Although these auxiliary structures do not play a major role in transmission or braking, they are crucial for the long-term reliable operation of the coupling.

The structural design of the brake drum geared coupling fully considers the convenience of installation and maintenance. Most products adopt a split design, which means that the brake drum and gear coupling can be installed separately for easy on-site assembly and later maintenance. At the same time, considering the installation space limitations of different devices, manufacturers usually offer various structural variants, such as brake drum built-in, external, flange connection, or shaft sleeve connection, to meet various mechanical layout requirements. This modular design concept enables the brake drum geared coupling to flexibly adapt to a wide range of application scenarios, from compact machine tools to large industrial equipment.

The working principle of the brake drum geared coupling is based on the integration of precision mechanical transmission and control technology, achieving dual functions of power transmission and motion braking. The operating mechanism of this coupling can be deeply understood from two dimensions: power transmission and braking control, and its outstanding performance characteristics stem from carefully designed structural features and the selection of high-quality materials.

The core of the power transmission mechanism lies in the unique meshing principle of the drum gear. When the driving shaft rotates, the drum shaped teeth on the outer gear sleeve drive the inner gear ring to rotate, thereby driving the driven shaft to rotate. The special shape of the drum teeth enables the gear pair to adapt to a certain degree of axis deviation during transmission. Compared with ordinary straight tooth couplings, the contact point of the drum shaped teeth will automatically adjust its position with the misalignment of the shaft system, always maintaining a larger contact area. In actual operation, even if there is axial displacement, radial offset, or angular deviation, the drum shaped tooth surface can automatically adjust the contact position through small relative sliding to avoid stress concentration. This adaptive feature enables the coupling to effectively compensate for shaft misalignment caused by manufacturing errors, installation deviations, or structural deformations during operation while transmitting high torque, protecting bearings and other transmission components from the effects of additional loads.

The implementation of brake control function relies on the brake drum mechanism integrated on the coupling. When the braking system is activated, the brake calipers or brake bands tightly clamp the rotating brake drum, converting kinetic energy into thermal energy through friction, thereby achieving deceleration or stopping of the equipment. The design of the brake drum takes into account thermal capacity and heat dissipation performance, ensuring that it will not fail due to overheating under frequent braking conditions. It is worth noting that the braking system of the brake drum geared coupling is usually used as a safety brake or holding brake, rather than the main working brake. This means that it is more used for anti slip braking after equipment stops or for safe braking in emergency situations, rather than speed regulation during daily operation. This division of labor enables the coupling braking system to focus on reliability and safety, without frequent actions, thereby extending its service life.

The core performance characteristics of the brake drum geared coupling are manifested in multiple aspects:

Excellent deviation compensation capability: The three-dimensional compensation capability of the drum gear coupling far exceeds that of ordinary couplings. Typical parameters show that this type of coupling can allow radial displacement of 0.4-6.3mm (depending on specifications), axial displacement of 2-10mm, and angular displacement of 1 ° -1.5 °. This compensation capability is not simply about "tolerating" deviations, but truly adapting to deviations through the optimization of gear meshing characteristics, ensuring that transmission efficiency is not significantly reduced due to misalignment of the shaft system. In practical industrial applications, this characteristic greatly reduces the requirements for installation accuracy and reduces the risk of failure caused by foundation settlement or thermal deformation.

Extremely high torque density: Thanks to the optimized design of drum shaped teeth, this type of coupling can transmit greater torque than straight tooth couplings at the same size, with an average increase in load-bearing capacity of 15% -20%. The torque transmission capacity of the large brake drum geared coupling can reach millions of Newton meters, which is sufficient to meet the most demanding heavy-duty requirements. High torque density means that in space constrained applications, engineers can choose more compact couplings without sacrificing transmission performance.

Dual function integration: Integrating transmission and braking functions into one not only saves installation space but also optimizes system dynamics performance. In traditional design, couplings and brakes need to be installed separately, occupying a large axial space, and the increase in inertia of the intermediate shaft section will affect the braking response. The integrated design shortens the transmission chain, reduces unnecessary rotational inertia, and makes braking more rapid and effective. Meanwhile, integrated design also simplifies the lubrication system, allowing gears and bearings to share the same lubrication scheme, reducing maintenance complexity.

Long service life: The drum shaped tooth design avoids the common edge wear problem of straight tooth couplings, and with a forced lubrication system, the tooth surface wear rate is only about 10% of that of grease lubrication. Practical applications have shown that the service life of high-quality brake drum geared couplings can reach more than 10 years under harsh working conditions such as metallurgical rolling mills. Long lifespan not only reduces spare parts costs, but also reduces downtime for maintenance and improves overall equipment utilization.

Efficient heat dissipation performance: The brake drum geared coupling has been designed with special consideration for thermal management issues. Circulating lubricating oil can not only lubricate gears, but also take away the heat generated by meshing friction and braking processes. Some high-end models also adopt hollow shaft structures or add heat dissipation fins to further enhance heat dissipation capabilities. Effective temperature control ensures the performance stability of the coupling under heavy load and frequent braking conditions, preventing material performance degradation or lubrication failure caused by overheating.

These excellent performances make the brake drum geared coupling an indispensable key component in the heavy industry field, demonstrating reliability and durability that ordinary couplings cannot match under extreme working conditions. By intelligently integrating transmission and braking functions, it not only simplifies mechanical system design, but also improves overall performance and safety, reflecting the highly integrated and functionally composite trend of modern mechanical design.