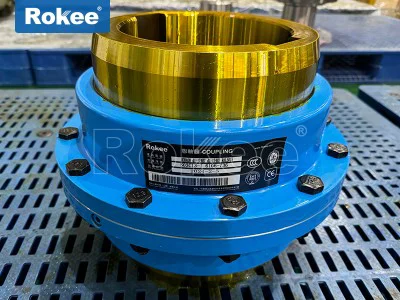

NL Nylon Sleeve Gear Couplings

NL nylon sleeve gear coupling is a special mechanical transmission component, belonging to a type of elastic coupling. It is made of nylon material to transmit torque through tooth meshing, and has the ability to buffer and absorb vibration, as well as compensate for axial, radial, and angular deviations. This type of coupling combines the high load-bearing capacity of metal gear couplings with the vibration reduction characteristics of elastic couplings, playing an important role in modern mechanical transmission systems.

Structural characteristics of NL nylon sleeve gear coupling

Core components:

Metal toothed shaft sleeve (usually made of high-quality alloy steel)

Nylon toothed elastic sleeve

Connecting bolts and fasteners

Protective cover (equipped on some models)Tooth shaped design features:

Adopting involute tooth profile or special curve tooth profile design

The number of teeth is generally between 30-60 teeth

The tooth surface is precision machined to ensure meshing accuracyMaterial characteristics:

The nylon sleeve is made of high wear-resistant nylon 6 or nylon 66 material

The metal components are made of high-quality steel such as 45 # steel and 40Cr

Some high-end models use MC nylon or reinforced nylon materials

Working principle and performance advantages of NL nylon sleeve tooth coupling

Torque transmission mechanism:

Transmitting torque through the meshing of nylon teeth and metal teeth

The elastic deformation of nylon material absorbs impact and vibration

The tooth flank clearance allows for a certain degree of deviation compensationMain performance advantages:

Vibration and noise reduction: The damping characteristics of nylon material effectively reduce the vibration and noise of the transmission system

Deviation compensation: can compensate for axial deviation of ± 1-5mm, radial deviation of 0.2-1.5mm, and angular deviation of 1 ° -3 °

Lubrication free maintenance: Nylon's self-lubricating properties reduce maintenance requirements

Electrical insulation: Nylon material provides excellent electrical insulation performance

Overload protection: In the event of overload, the nylon sleeve can be damaged before other components, protecting critical equipment

Selection considerations for NL nylon sleeve toothed coupling:

The required torque to be transmitted

Deviation of alignment between two axes

Working environment temperature and medium

Speed range and vibration requirements

Installation space restrictions

Key points for installation and maintenance

Installation steps:

Check the compatibility between the coupling model and the equipment

Clean the shaft end and coupling inner hole

Use hot fitting method (heat the nylon sleeve to 80-100 ℃) or special tools for press fitting

Gradually and evenly tighten the connecting bolts

Check the alignment status (laser alignment is recommended)Daily maintenance:

Regularly check the wear of nylon sleeves

Observe for any abnormal vibrations or noise

Check the tightening status of bolts

Avoid contact with corrosive media such as strong acids and alkalisCommon troubleshooting:

Nylon sleeve wear: replace with a new nylon sleeve

Abnormal vibration: Re center or inspect the equipment foundation

Decreased transmission torque: Check if the nylon sleeve is aging or damaged

NL nylon sleeve gear couplings are widely used in various industrial fields:

General machinery: pumps, fans, compressors, etc

Construction machinery: cranes, excavators, concrete machinery, etc

Metallurgical equipment: rolling mill, continuous casting machine, straightening machine, etc

Mining machinery: crushers, ball mills, conveying equipment, etc

Power generation equipment: steam turbine, generator, water turbine, etc

Shipbuilding industry: propulsion systems, deck machinery, etc

NL gear couplings occupy an important position in the field of mechanical transmission due to their excellent comprehensive performance. With the advancement of materials science and manufacturing technology, its performance will be further improved and its application scope will continue to expand.