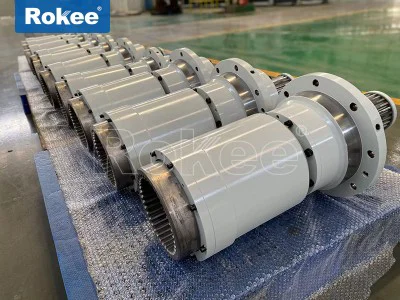

Spherical Gear Couplings

The spherical gear coupling consists of an inner ring gear and a half coupling with spherical outer teeth. Its core feature is that the outer teeth are machined into a spherical profile, and the center of the spherical surface is located on the gear axis. This design transmits torque through spherical meshing between tooth surfaces, while allowing for greater axial, radial, and angular displacement compensation. Compared to traditional spur gear couplings, spherical contact can increase torque transmission capacity by 15% -30% and significantly reduce edge stress concentration.

Performance Advantage

Dynamic compensation capability

Angular compensation: allows axis deviation of 1.5 ° -2.5 °, and extreme working conditions can reach 6 °;

Radial compensation: can adapt to parallel offset of 0.01-0.02 inches;

Axial floating: Absorb axial displacement through tooth flank clearance design.

Efficient transmission

The transmission efficiency is as high as 99.7%, and the torque carrying range covers 1000N · m to 4500kN · m, suitable for low-speed heavy-duty (such as metallurgical rolling mills) and high-speed precision (such as gas turbines) scenarios.

Lifespan and Maintenance

Spherical meshing increases the contact area by more than 50% (tooth width direction ≥ 70%, tooth height direction ≥ 50%), and with regular maintenance of lithium based grease, the service life can reach 1.3-1.5 times that of traditional drum shaped gear couplings.

Application Field

Heavy industry: metallurgical rolling mills, mining crushers (capable of withstanding instantaneous impact loads);

Energy equipment: wind turbine main shaft, gas turbine (requiring dynamic balance accuracy ≤ 0.03mm);

Special machinery: marine propulsion system, lifting equipment drum (compensating drum and reducer shaft deviation).