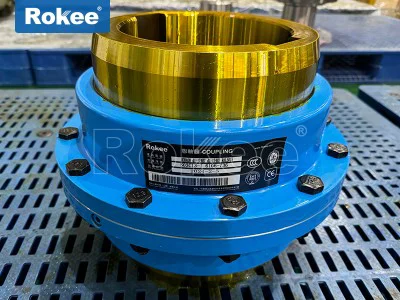

Curved Tooth Couplings

As a key component in the modern industrial transmission field, the curved tooth coupling has become an indispensable connecting device in heavy machinery and precision equipment due to its unique structural design and excellent performance. This type of rigid flexible coupling, through innovative drum shaped tooth surface design, not only achieves efficient transmission of large torque, but also effectively compensates for installation deviations in axial, radial, and angular directions, solving many limitations of traditional spur gear couplings in complex working conditions.

Curved tooth coupling is a precision transmission component composed of an inner gear ring and a flange half coupling with outer teeth. Its core technical feature lies in the special geometric shape of the outer gear. Compared with traditional spur gear couplings, the external teeth of drum gear couplings are not simply straight teeth, but adopt innovative spherical design - the external teeth are made into a spherical profile centered on the gear axis, while increasing the tooth flank clearance. This structural innovation has brought significant performance improvements.

The geometric characteristics of drum shaped teeth are manifested by the fact that both the tooth tip and tooth surface are arc-shaped, forming a double joint structure throughout the coupling, which endows the device with excellent flexibility compensation capability. When the tooth tip of the external gear shaft sleeve is machined into a circular arc shape, the tooth profile presents a distinct drum shaped feature in the cross-section of the tooth center plane and tangent to the pitch cylindrical surface. This drum shaped tooth surface is formed by gradually shifting and superimposing different end sections, and the dotted line formed by the displacement and axial coordinates is called the drum curve, which is a key geometric parameter of the curved tooth coupling. The bulge curve is mostly a segment of arc (some designs also use three segments of arc), and the choice of bulge radius directly affects the compensation ability of the coupling and the distribution of tooth contact stress.

In terms of working mechanism, the curved tooth coupling achieves functional advantages through a unique tooth surface contact method. When there is relative displacement between the two axes, the drum shaped tooth surface significantly improves the contact conditions between the inner and outer teeth: under angular displacement conditions, it avoids the common tooth end edge squeezing phenomenon in straight tooth couplings and eliminates stress concentration points; Simultaneously optimized the friction state of the tooth surface, making the load distribution more uniform. This design enables the coupling to adaptively compensate for a certain range of axis deviations while transmitting torque, including axial displacement (deviation along the axis direction), radial displacement (two axis centerlines parallel but not overlapping), and angular displacement (two axis centerlines forming a pinch angle).

From the perspective of materials science and manufacturing technology, high-quality curved tooth couplings are usually made of high-quality alloy steels such as 42CrMo, 20CrMnTi, etc. After precision carburizing and quenching processes, the tooth surface hardness reaches HRC58-62, ensuring high wear resistance and long-term service life.

In terms of load-bearing capacity and transmission efficiency, the curved tooth coupling performs particularly well. Under the same outer diameter of the inner gear sleeve and maximum outer diameter of the coupling, its load-bearing capacity is on average 15% to 20% higher than that of a spur gear coupling. This is mainly due to the optimized contact stress distribution of the drum shaped tooth surface, which avoids stress concentration caused by edge contact.

The displacement compensation capability is another major advantage of drum gear couplings. When the radial displacement is zero, the allowable angular displacement of a spur gear coupling is usually only 1 °, while a drum gear coupling can reach 1 ° 30 ', increasing the compensation capacity by 50%. This enhanced angular compensation capability enables it to better adapt to shaft installation errors and dynamic deformations during operation. In practical applications, the maximum allowable inclination angle of the curved tooth coupling can reach 6 ° (generally recommended range is 1.5 °~2.5 °), and it can also compensate for certain axial and radial displacements, greatly reducing the requirements for installation accuracy.

From the perspective of service life and maintenance cycle, the drum tooth design has brought a qualitative leap. The drum shaped tooth surface avoids the common problem of edge compression at the tooth end of straight tooth couplings, while improving the friction condition of the tooth surface, resulting in even distribution of wear. The curved tooth coupling with forced thin oil lubrication has a tooth surface wear of only about 10% of that of grease lubrication. Circulating thin oil not only lubricates the tooth surface, but also takes away the rolling heat at the rolling mill end and the heat generated by tooth friction, effectively preventing a decrease in the allowable contact stress on the surface of the tooth material.

The convenience of installation and maintenance cannot be ignored. The outer gear sleeve of the curved tooth coupling usually has a trumpet shaped tooth end, making it very easy to assemble and disassemble the inner and outer teeth. Some advanced designs are also equipped with intelligent lubrication systems, such as oil collection groove structures - oil collection grooves are machined in the outer gear shaft holes, and oil holes are drilled at the bottom of the tooth grooves to communicate with the oil collection grooves. The centrifugal force generated by high-speed operation is used to spray oil into the meshing area, achieving automatic lubrication. This design is particularly suitable for situations where frequent maintenance is inconvenient, and some models can achieve 10000 hours of maintenance free operation.

Common series include multiple models such as GICL, GIICL, GCLD, WGP, WGC, WGZ, etc. The GICL and GIICL series are basic curved tooth couplings, particularly suitable for low-speed and heavy-duty working conditions, such as metallurgy, mining, lifting and transportation industries. The GIICL type is further divided into Type I and Type II: Type I adopts a separated sealing end, allowing for larger radial displacement and adapting to Y, J1, and Z1 axial extensions; Type II is an integral sealed end with a more compact structure, suitable for Y and J1 type shaft extensions. GCLD type is a curved tooth coupling with an intermediate shaft, suitable for shaft connections in long-distance transmission. WGP type is a curved tooth coupling with brake discs, commonly used for equipment that requires rapid braking; WGC type is a vertically installed curved tooth coupling designed specifically for transmission systems with vertical installation; The WGZ type is a curved tooth coupling with brake wheels that integrates braking function.

From the perspective of functional configuration, drum gear couplings can be divided into ordinary type, brake type, vertical installation type, intermediate shaft type, etc. Ordinary models such as GICL, GIICL, etc. are mainly used for conventional power transmission; Braking types such as WGP, WGZ, NGCL, etc., integrate brake discs or brake wheels and are widely used in equipment such as cranes and mining hoists that require rapid braking; Vertical installation types such as WGC are specifically designed for connecting vertical shaft systems such as vertical pumps and vertical reducers; Intermediate shaft types such as WGJ, GCLD, etc. adapt to the transmission requirements of large shaft spacing by adding intermediate shafts. These different types meet the transmission needs of various complex working conditions, providing users with flexible selection space.

In terms of performance parameter range, the curved tooth coupling covers a wide range of applicable requirements. The nominal torque range is from 0.4kN · m to 4500kN · m, which can meet different torque requirements from small equipment to heavy machinery; The diameter range of the shaft hole is from 16mm to 1040mm, suitable for various shaft diameters; The maximum allowable speed can reach 4000r/min, which is suitable for low-speed heavy-duty situations and can also meet some high-speed transmission requirements.