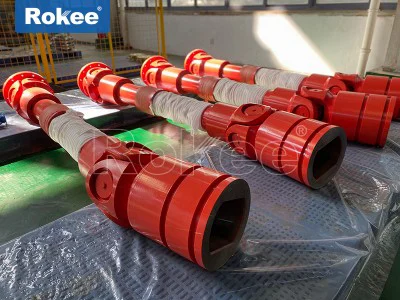

Cardan Universal Joints

As a core component in mechanical transmission systems, cardan universal joints play an indispensable role in fields such as automobiles, industrial equipment, and aerospace. It is like the joints of the human body, capable of flexibly transmitting power at different angles, making the mechanical system more adaptable and functional.

Universal joint is a mechanical device that enables variable angle power transmission, mainly used for parts that require changing the direction of the transmission axis. Its core function is to connect two axes that are not on the same straight line and allow the angle between them to vary within a certain range, while reliably transmitting rotational motion and torque.

Structurally, the cardan universal joint is similar to the joints of the human limbs. Just as our wrists can bend and rotate in multiple directions, universal joints also allow for changes in the relative position between connected mechanical components. In the automotive transmission system, this characteristic is particularly important because the relative position between the transmission and the drive axle will constantly change with factors such as uneven road surfaces and load changes during vehicle operation. The universal joint ensures smooth power transmission under these dynamic conditions through its flexibility and adaptability.

In terms of basic working principle, the simplest cross axis universal joint consists of two universal joint forks and a cross axis. When one universal joint fork rotates, it drives the other universal joint fork to rotate through the cross shaft, and can swing in any direction around the center of the cross shaft. The setting of needle roller bearings reduces friction and makes rotation smoother. However, this basic design has an inherent characteristic: when there is an angle between the two shafts, the speed of the output shaft will fluctuate periodically, even if the input shaft maintains a constant speed. This inequality needs to be overcome through paired use of universal joints or other more advanced designs.

According to different classification standards, cardan universal joints can be divided into multiple types, each with its unique structural characteristics and applicable scenarios. From the perspective of torsional elasticity, it can be divided into two categories: rigid universal joints and flexible universal joints. Rigid universal joints can be further divided into three main types: non constant velocity universal joints, quasi constant velocity universal joints, and constant velocity universal joints.