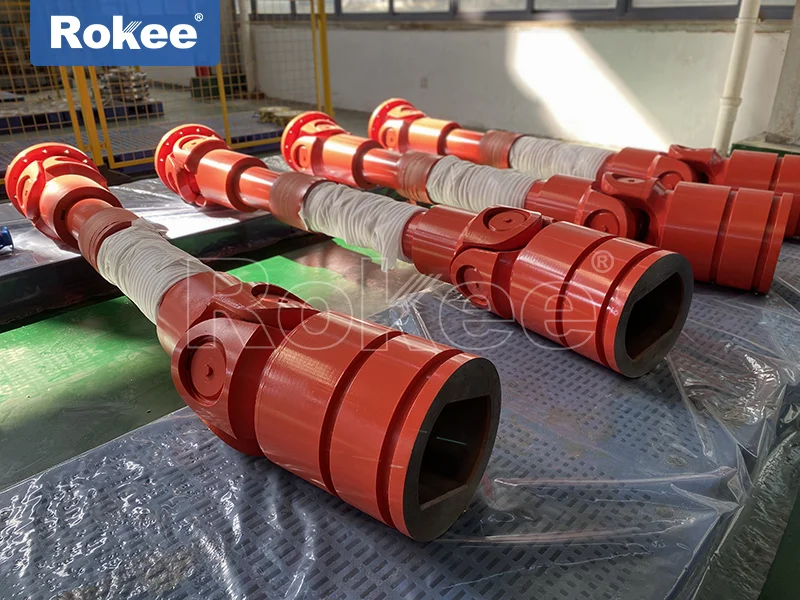

Cardan Shaft Couplings

As a key component in mechanical transmission systems, cardan shaft coupling plays an indispensable role in modern industrial fields. This device, which can connect different axes and achieve power transmission, has undergone continuous technological innovation and application expansion since its inception.

Universal shaft coupling is a mechanical device used to connect different axes and transmit torque and rotational motion. Its core function is to compensate for the angular deviation, radial displacement, and axial displacement between the two axes, so that the driving shaft and the driven shaft can maintain continuous rotation even in the presence of certain deviations. This unique performance makes it an ideal choice for solving complex transmission problems.

From the perspective of kinematic principles, universal couplings work based on multi-body dynamics theory. The master-slave axis rotation angle relationship model established in the right-handed coordinate system shows that the speed ratio relationship between the driving axis rotation angle φ ₁ and the driven axis rotation angle φ ∝ can be expressed as φ ∝/φ ₁=1-sin ² φ ₁ cos ² β. This formula is derived through coordinate transformation in the connected coordinate system and is completely consistent with the results of traditional vector calculation algorithms. When a single cardan shaft coupling is working, if there is an angle β between the two shafts, the angular velocity of the driven shaft will experience periodic fluctuations, and the amplitude of the fluctuations is proportional to the size of the β angle. This fluctuation will generate additional dynamic loads in high-speed transmission, affecting the smoothness of the transmission. To solve this problem, a dual cardan shaft coupling arrangement is commonly used in practical applications, which is designed with an equal angle between the intermediate shaft and the master and slave shafts, and ensures that the two end joints of the intermediate shaft are in the same plane, thereby ensuring stable angular velocity output of the slave shaft.

The core advantage of universal couplings lies in their excellent angle compensation capability. The allowable angle range between the two axes for universal couplings of different structural types is usually between 5 ° and 45 °, depending on the design and application requirements. This ability makes it irreplaceable in situations where installation is difficult or relative displacement occurs during work. Meanwhile, modern universal couplings also have the characteristics of compact structure and high transmission efficiency (up to 98-99.8%), demonstrating significant energy-saving effects in high-power transmission.

From a material perspective, universal couplings are usually made of materials such as 45 steel, 45 forged steel, 40 chromium or cast iron, which have good mechanical properties and wear resistance, and can meet the requirements of different working conditions. As a vulnerable component of universal couplings, the quality and lifespan of bearings directly affect the overall service life of the coupling. Therefore, high-end universal couplings often use special bearing steel and advanced surface treatment technology to extend the bearing lifespan.

After long-term development, universal shaft couplings have formed diverse structural forms, each with its unique advantages and application scenarios. A deep understanding of these structural types and their technical characteristics is crucial for the correct selection and use of universal couplings.

Cross axis cardan shaft coupling is the most common and widely used type. Its core components consist of a cross shaft, bearing sleeve, flange fork, etc., and angle compensation is achieved through the rotation of the cross shaft. According to the different structures of the bearing seat, the cross shaft type is divided into various forms such as SWC type integral fork head type, SWP type partial bearing seat type, and SWZ type integral bearing seat type. Among them, the SWC-BH model adopts an integral fork head design, making operation more reliable. The cross axis cardan shaft coupling has the characteristics of large angle compensation capability (up to 45 °), compact structure, and strong load-bearing capacity, and performs excellently in heavy equipment such as steel rolling machinery, lifting and transportation machinery, and engineering machinery. Compared with other types of couplings with the same rotational diameter, it can transmit greater torque, which is particularly important for mechanical equipment with limited rotational diameter. The SWP-ZG positive flange through type cross shaft cardan shaft coupling improved in 2023 adopts a split bearing seat cover design, which facilitates bearing replacement and makes product maintenance more convenient.

The ball cage cardan shaft coupling (constant velocity cardan shaft coupling) represents a more advanced technological solution. This type of coupling achieves true constant speed transmission through precise coordination of multiple steel balls in the inner and outer raceways, eliminating the speed ratio fluctuation problem of traditional cardan shaft couplings. Ball cage couplings are divided into two categories: fixed and sliding. Fixed couplings come in various forms such as disc, cup, bell, and cylinder. Its typical characteristics are smooth transmission, low noise, and high allowable speed, making it particularly suitable for precision transmission applications. In equipment such as cold rolling lines, shearing lines, and high-speed precision slitting machines, ball cage couplings exhibit excellent performance. The HTJ type ball cage coupling adopts a linear raceway design, which makes axial expansion and installation distance adjustment more convenient. It is widely used in the transmission system of multi roll straightening machines in the petroleum machinery and non-ferrous metal industries.

The dual cardan shaft coupling is a composite structure composed of two sets of cardan shaft couplings, which are connected by an intermediate shaft to effectively solve the speed fluctuation problem of a single cardan shaft coupling. The combined double cardan shaft coupling used in cigarette packaging equipment connects the left and right coupling components through a central axis, positioning pins, and locking bolts, significantly reducing maintenance time from 4.5 hours to 1.2 hours and improving equipment maintenance efficiency. The core advantage of the dual cardan shaft coupling lies in its wide range compensation capability, which can support axial/radial composite displacement compensation. The maximum angular displacement compensation is about 40% higher than that of the single cardan shaft coupling, while maintaining the precision and stability of the transmission.

In addition to the main types mentioned above, universal couplings also include various structural forms such as ball fork type, convex block type, ball pin type, ball joint type, and three pin type. According to the magnitude of the transmitted torque, it can be divided into heavy, medium, light, and small; According to the application field, it can be divided into universal and specialized types (such as special couplings for automobiles, agricultural machinery, ships, etc.). With the advancement of materials science and manufacturing technology, new types of universal couplings continue to emerge, such as intelligent universal couplings using composite materials, self-lubricating functions, or integrated sensing functions, providing more diversified choices for various industries.

The correct selection of cardan shaft coupling is a key link to ensure the reliable operation of mechanical transmission systems. Improper selection may lead to premature failure, reduced efficiency, and even safety accidents. The scientific selection process requires comprehensive consideration of multiple factors and adherence to a systematic approach.

Before selecting, a series of prerequisites must be clearly defined: the type, power, and speed characteristics of the prime mover; Is there a deceleration or acceleration device in the transmission system; The nature of the load (constant load, pulsating load, or bidirectional alternating load); Installation status (horizontal, vertical, or tilted, tilt angle size); Working environment (whether there are harsh conditions such as high temperature, dust, water spray, chemical corrosion, etc.); The connection form and specific installation size requirements at both ends of the coupling; Speed range and dynamic balance requirements; Compensation methods for axial dimension errors, etc. These factors together form the basis for selection. For example, in the high-temperature environment of the metallurgical industry, it is necessary to choose high-temperature resistant materials and consider the impact of thermal expansion; In the field of chemical engineering, attention should be paid to the corrosion resistance of couplings.