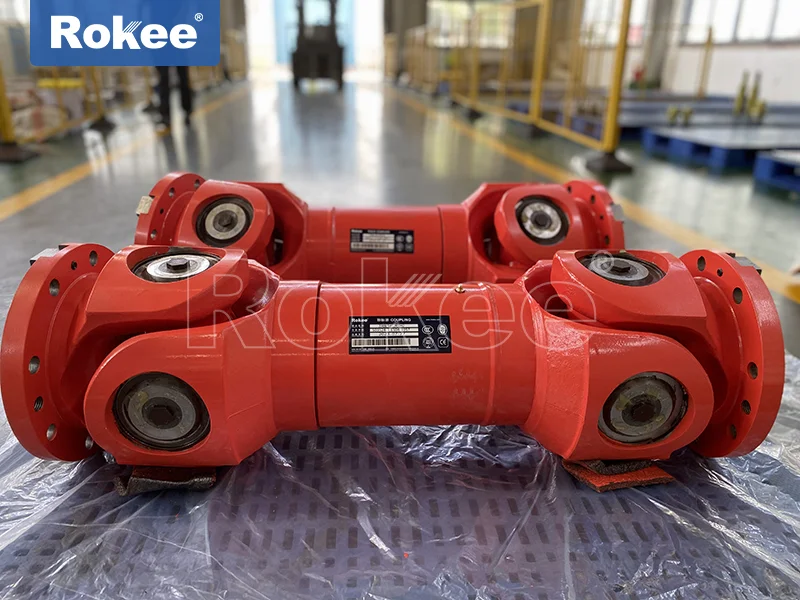

Universal Joint Shafts

Universal joint shaft is a mechanical device that achieves non concentric axis power transmission through a hinge structure, and its core function is to compensate for the angular deviation and position offset between two axes.

A typical structure includes components such as a cross shaft, bearing sleeve, flange fork, etc., which offset installation errors through relative motion of the components and are suitable for working conditions with axial/radial/angular composite displacement.

Mainstream type

Cross axis universal joint

Adopting a cross cross axis structure, it has a high load-bearing torque and low cost, but requires regular lubrication. The SWC series integral fork design increases the bearing life by 30%.Ball cage universal joint

Spherical raceway transmission ensures a speed fluctuation rate of less than 1%, suitable for high-speed scenarios.Double universal joint

Realize complete constant speed transmission through the design of intermediate shaft equal angle.Ball joint universal joint

The integral connecting sleeve structure increases the radial bearing capacity by 52%.