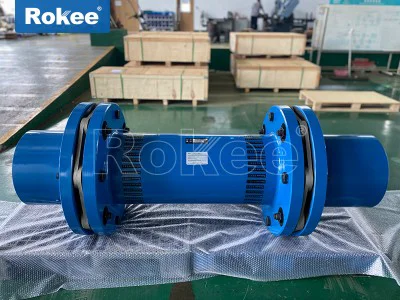

Flexible Diaphragm Couplings

Flexible diaphragm coupling is a high-performance metal elastic element flexible coupling, which is composed of a diaphragm group composed of multiple layers of stainless steel thin plates stacked together and connected by bolts in a staggered manner to form two halves of the coupling.

The core principle of flexible diaphragm coupling is to compensate for the axial, radial, and angular displacement between two shafts through the elastic deformation of the diaphragm, achieving efficient transmission without lubrication. Typical structures are divided into:

Single diaphragm coupling: suitable for low eccentricity scenarios, with a simple structure but limited compensation capability.

Double diaphragm coupling: By synergistically deforming two sets of diaphragms, it can simultaneously handle multi-directional deviations, and its angular displacement compensation capability is twice that of traditional gear couplings (about 1.5 °).

Core performance characteristics

High precision transmission

The transmission efficiency is as high as 99.86%, with no rotational clearance, and can accurately transmit speed, suitable for precision machinery such as servo systems.

Zero rotation clearance design ensures the response speed and positioning accuracy of the motion control system.Excellent environmental adaptability

Wide temperature resistance range (-80 ℃ to+300 ℃), stable operation in corrosive media (acid, alkali) and high vibration conditions.

No need for lubrication and maintenance, avoiding oil pollution, suitable for industries with high cleanliness requirements such as food and medicine.Dynamic performance optimization

The metal diaphragm absorbs vibration, reduces bearing load, reduces noise below 65dB (A), and significantly extends equipment life.

Strong impact resistance, with peak torque carrying capacity up to twice the rated value.

Application Fields and Typical Cases

Energy industry: coupling of gas turbines and steam turbines to compensate for shaft displacement caused by thermal expansion.

Process industry: corrosion-resistant transmission of high-power chemical pumps (such as sulfuric acid transfer pumps).

High end equipment: Helicopter main rotor transmission system, meeting the requirements of lightweight and high reliability.

Intelligent manufacturing: CNC machine tool feed axis connection ensures micrometer level transmission accuracy.

Installation specifications

Use a torque wrench to tighten the bolts in stages (50% rated torque first, then 100%), ensuring a flange clearance of 0.2-0.3mm.

When multiple deviations coexist, the compensation amount should be controlled at 50% of the allowable value.

Life management

Regularly check for fatigue cracks in the diaphragm (it is recommended to stop the machine every 5000 hours for inspection).

Apply molybdenum disulfide coating on the bolt threads to prevent micro motion wear.