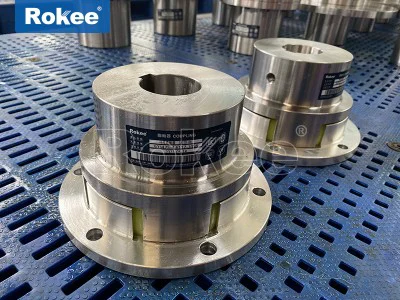

Curved Jaw Couplings

Curved jaw coupling is a commonly used type of elastic coupling, named after its structural characteristics resembling interlocking claws. This type of coupling transmits torque through elastic elements and can compensate for certain axial, radial, and angular deviations, playing an important role in industrial transmission systems.

Main components

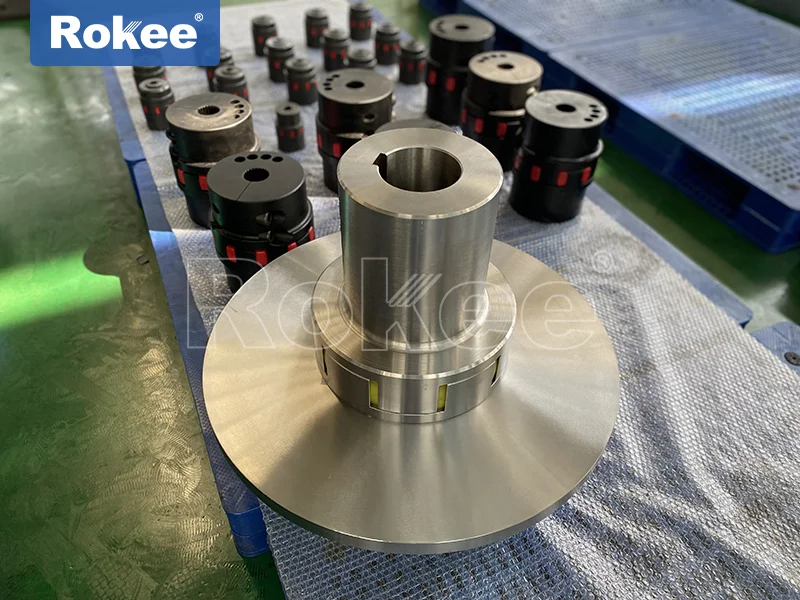

Two metal flanges: typically made of aluminum alloy, steel, or stainless steel, each flange end has multiple curved protrusions ("claws")

Elastic body (spider): a star shaped component made of polyurethane, rubber, or other elastic materials, located between two flanges

Tightening components: bolts, nuts, etc. used to fix the coupling and shaft end

When power is input from one end, the claws on the driving side transmit torque to the claws on the driven side by compressing the elastic body. Elastic bodies absorb vibrations and impacts while transmitting torque, and allow for a certain degree of axial deviation.

Advantages:

Shock absorption and buffering: Elastic components effectively absorb vibrations and impact loads

Deviation compensation: can compensate for angular deviation of 0.5 ° -3 ° and radial deviation of 0.1-0.5mm

Easy to maintain: no lubrication required, easy replacement of elastomers

Stable torque transmission: seamless transmission, smooth start and stop

Electrical insulation: elastomers provide electrical isolation to prevent stray currents

limitations:

Limited compensation capability, not suitable for large deviation situations

The elastomer has aging issues and requires regular inspection

Performance will decrease in high temperature environments (generally operating temperature range -40 ℃ to+100 ℃)

The main types of curved jaw couplings

Standard curved jaw coupling: The most common form, suitable for general industrial applications

Heavy duty curved jaw coupling: increased size and strength for high torque applications

Micro curved jaw coupling: miniaturized design for precision instruments and small equipment

Special material coupling: such as stainless steel material used in special industries such as food and medicine

Key points for selecting claw type couplings

Torque demand: Calculate the torque required by the system (including peak torque)

Speed range: Consider the maximum allowable speed of the coupling

Shaft diameter matching: Choose a coupling that is suitable for connecting the shaft size

Environmental conditions: Effects of temperature, humidity, chemicals, etc. on elastomers

Deviation requirement: Evaluate the amount of axis deviation that the system may produce

Space limitations: Consider size constraints for installation space

Application fields of curved jaw couplings

General industrial machinery: pumps, fans, compressors, etc

Automation equipment: robots, CNC machine tools

Food processing equipment: specially designed to meet hygiene requirements

Packaging machinery: occasions requiring precise transmission

Power generation equipment: connection of small generator sets

Installation steps:

Check the size matching between the shaft end and the coupling

Clean the contact surface between the shaft and coupling

Assemble using the correct method (avoid hammering)

Uniformly tighten the bolts to the specified torque

Check the axial clearance and coaxiality

Maintenance suggestion:

Regularly check the wear of the elastomer

Observe the vibration and noise during the operation of the coupling

Check the bolt tightening status every 6-12 months

The replacement cycle of elastomers is generally 3-5 years (depending on the usage conditions)

Record maintenance history and replacement component information

Curved jaw couplings have been widely used in the field of industrial transmission due to their advantages of simple structure, reliable performance, and easy maintenance. The correct selection and use of curved jaw couplings can effectively improve the efficiency of transmission systems and extend the service life of equipment, making them an indispensable key component in modern mechanical design.