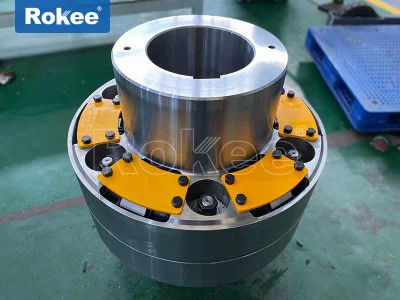

Flange Couplings

Flange coupling is a rigid connection device widely used in industrial machinery transmission systems, mainly used to connect two shafts to transmit torque and rotational motion. This type of coupling has become an indispensable component in modern mechanical transmission systems due to its simple structure, easy installation, and high torque transmission.

The flange coupling is composed of two flange plates (flange half coupling) connected by bolts, and has the following significant features:

Rigid connection design, capable of accurately transmitting motion and torque

Compact structure, small footprint

The installation has high requirements for neutrality

Suitable for high torque transmission scenarios

The main types and characteristics of flange couplings

Standard flange coupling

The most common type consists of two flanged shaft sleeves and a set of connecting bolts, suitable for most conventional transmission applications. Standard flange couplings can be subdivided into:

Flange type flange coupling

Flat flange coupling

Equipped with a flange coupling for the middle ringHeavy duty flange coupling

Specially designed for high torque applications, with thickened flanges and higher strength connecting bolts, commonly used for:

Heavy machinery

mining equipment

Large scale generator setPrecision flange coupling

Made with precision machining technology, it has extremely high coaxiality and balance, suitable for:

precision machine tool

High speed rotating equipment

measuring instrumentCorrosion resistant flange coupling

Using stainless steel or special coating treatment, suitable for:

chemical equipment

marine environment

Food processing machinery

When choosing a flange coupling, the following key parameters need to be considered:

Torque capacity: The maximum torque value that a coupling can transmit

Shaft diameter range: Suitable shaft diameter size range

Maximum speed: the highest rotational speed for safe operation

Allowable deviations: axial deviation, radial deviation, angular deviation.

Inertia moment: an important parameter that affects the dynamic performance of a system

Material characteristics: usually cast iron, cast steel, stainless steel or alloy steel

Selection Guide for Flange Couplings

Selection considerations

Transmission power and torque requirements

Shaft diameter size

Working environment (temperature, humidity, corrosiveness, etc.)

speed range

Installation space restrictions

Do you need insulation propertiesSelection steps

Determine the transmitted torque and speed

Consider operating condition factors (impact, vibration, etc.)

Choose appropriate size specifications

Check installation size compatibility

Confirm material suitability

Installation and maintenance of flange couplings

Installation key points

Ensure the accuracy of two axis alignment

Use appropriate installation tools

Tighten the bolts according to the specified torque value

Check the balance of the couplingroutine maintenance

Regularly check the tightening status of bolts

Monitor vibration and noise changes

Check the condition of the seals (if applicable)

Regular lubrication (required for certain types)Common faults and their solutions

Loose bolts: tighten or replace in a timely manner

Alignment deviation: recalibration

Flange deformation: replace damaged parts

Abnormal vibration: check balance and alignment

Flange couplings are widely used in:

Industrial machinery: pumps, fans, compressors, etc

Power generation equipment: steam turbine, generator, etc

Shipbuilding industry: propulsion systems, auxiliary machinery

Petrochemical equipment: various rotating mechanical connections

Metallurgical industry: rolling mills, conveying equipment

As a key component in mechanical transmission systems, the performance of flange couplings directly affects the operational efficiency and reliability of the entire system. The correct selection, installation, and maintenance of flange couplings are of great significance for extending equipment life and improving production efficiency.