Cross Type Universal Joints

Cross type universal joint is an important transmission component in the field of mechanical engineering, widely used in various situations that require power transmission and allow for a certain angle between the two axes.

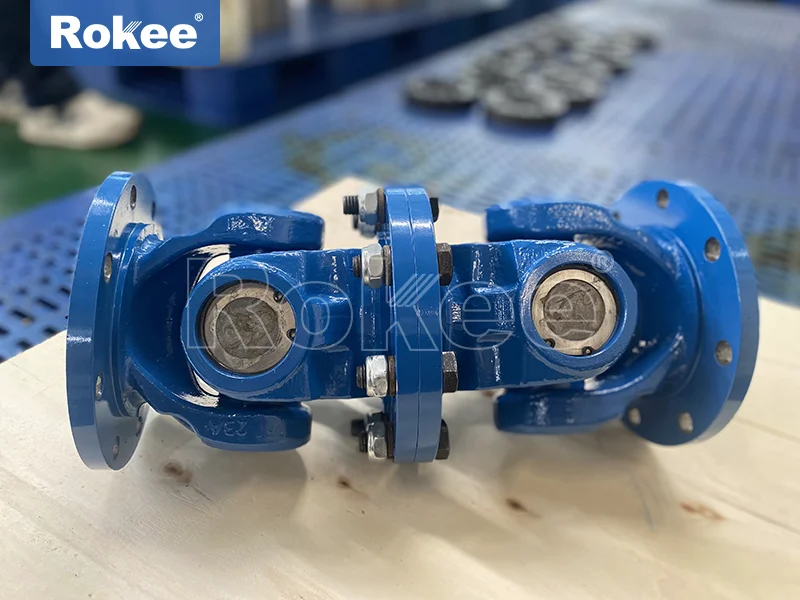

The cross type universal joint is a typical non-uniform universal joint, and its core structure consists of the following parts:

Cross shaft: As the core component of the entire universal joint, it is usually made of high-strength alloy steel and undergoes precision machining and heat treatment to improve wear resistance and load-bearing capacity.

Universal joint fork: There are usually two, which connect the input shaft and output shaft respectively, and are connected to the cross shaft through bearings. According to different structures, it can be divided into two designs: integral fork heads and split fork heads.

Bearing components: Needle roller bearings are usually used and installed between the cross shaft and the universal joint fork to reduce friction and withstand radial loads.

This structure enables the cross type universal joint to transmit torque and rotational motion at an angle between the two axes (usually within the range of 5 ° -45 °). However, it should be noted that when there is an angle between the two shafts, the rotational speed of the output shaft will exhibit periodic fluctuations, therefore it belongs to the "non-uniform universal joint".

The cross shaped universal joint has several outstanding technical features:

Angular compensation capability: Standard cross type universal joints can provide angular compensation capability of over 25 °, and specially designed products can even achieve larger compensation angles.

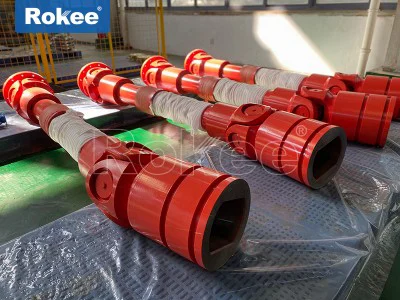

Axial displacement adaptability: Some models (such as SWP type) adopt a split fork design, which can adapt to a certain degree of axial displacement and is suitable for heavy-duty equipment with a rotation diameter of up to 1200mm.

Torque transmission capability: The SWC type integral fork structure can cover a rotation diameter of 1600mm and a torque transmission distance of over 30 meters, making it particularly suitable for steel rolling machinery and heavy transportation equipment.

Transmission efficiency: A well-designed cross shaped universal joint has high transmission efficiency and low noise, but the transmission efficiency decreases with the increase of the angle between the two axes.

Service life: Under normal working conditions and appropriate maintenance, the service life of cross type universal joints can reach thousands of hours, with key influencing factors including lubrication conditions, load characteristics, and installation accuracy.

Classified by structure:

Cross axis universal joint (most common)

Ball cage cross universal joint

Ball fork cross universal joint

Convex block cross universal joint

Three pin cross universal joint

Classified by carrying capacity:

Heavy duty: such as SWC type, suitable for heavy-duty applications such as metallurgy and mining

Medium size: such as SWP type, suitable for construction machinery, etc

Lightweight and compact: such as WSD type, suitable for precision machinery and control machinery

Special design type:

Scalable type: such as WSP type, with sliding spline structure, can compensate for axial displacement

High speed type: adopting a special balance design, suitable for high-speed occasions

Corrosion resistant type: made of stainless steel and other materials, suitable for corrosive environments such as chemical and marine industries

Cross shaped universal joints are widely used in many industrial fields due to their unique performance advantages

Automotive industry: Used for transmission systems, especially for rear wheel drive vehicles, to solve the problem of relative position changes between the engine and the drive axle.

Metallurgical equipment: applied to the main transmission system of steel rolling mills, capable of withstanding heavy loads and adapting to the adjustment and movement of rolling rolls.

Construction machinery: In the transmission system of equipment such as excavators and cranes, it adapts to various motion postures of the working device.

Petroleum machinery: In the rotating system of drilling equipment, it transmits large torque and adapts to the inclination of the wellhead.

Rail transit: In the drive system of locomotives and vehicles, the problem of relative motion between the motor and the wheel axle is solved.

Precision Machinery: Used in equipment such as machine tools and robots for applications that require precise transmission.

Agricultural machinery: power transmission systems for tractors, harvesters, and other equipment.

Installation technical requirements:

Thoroughly clean all parts and remove burrs before assembly

Ensure that the centerlines of the two welded fork bearing holes in the middle are on the same plane, with a permissible deviation of no more than 1 °

The spline part should slide freely and the joint rotation should be flexible

Except for the flange end face and end face key, which need to be coated with anti rust grease, the rest of the parts should be coated with anti rust primer and painted

Daily maintenance:

Regular lubrication is crucial. It is recommended to lubricate once a week under standard operating conditions, and daily lubrication is necessary under high temperature conditions

Adjust the cross axis by 180 ° during each disassembly to alternate the use of the cross axis journal and balance wear

Regularly check the bearing clearance and wear of the cross shaft

Pay attention to the vibration and noise changes during operation, and promptly detect any abnormalities

Fault diagnosis:

Abnormal vibration: may be caused by wear, imbalance, or poor alignment

Overheating: usually related to poor lubrication or overload

Increased noise: often indicates increased wear on bearings or cross shafts

Precautions for purchasing:

Clear operating conditions: including parameters such as transmitted torque, speed, and range of two axis angle

Determine installation dimensions: including shaft diameter, spline specifications, flange dimensions, etc

Consider environmental factors such as temperature, humidity, corrosiveness, etc., and choose appropriate materials and sealing forms

Evaluate supplier qualifications: prioritize selecting suppliers with professional technical capabilities and comprehensive after-sales service

Although the cross shaped universal joint has a relatively simple structure, it plays an irreplaceable role in mechanical transmission systems. From heavy metallurgical equipment to precision instruments, from traditional automobiles to emerging robotics fields, its presence is everywhere. Understanding the working principle, selection criteria, and maintenance points of cross type universal joints is of great significance for mechanical designers, equipment maintenance personnel, and procurement personnel. With the continuous development of industrial technology, this classic mechanical component will continue to evolve, providing reliable transmission solutions for more complex and precise mechanical systems.