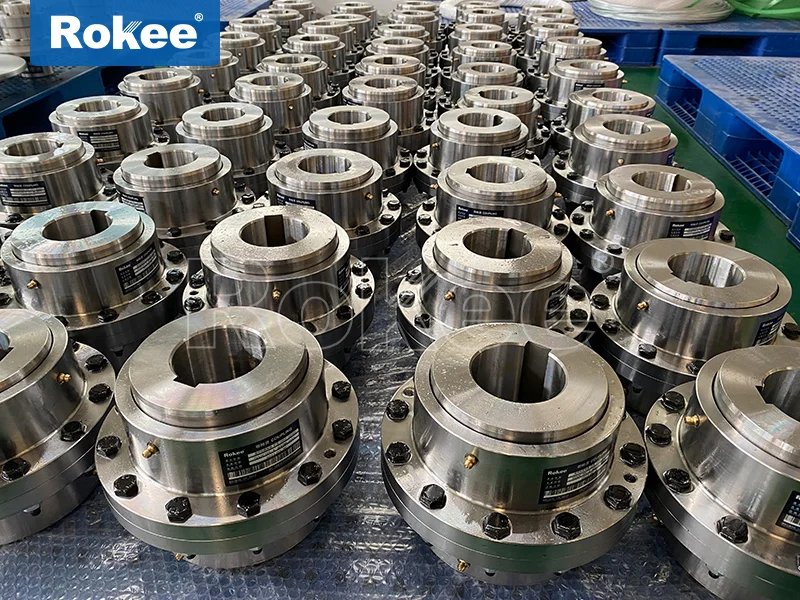

Geared Couplings

Geared couplings as key components in the field of mechanical transmission, play a crucial role in modern industrial equipment. This precision device that achieves power transmission through gear meshing can not only efficiently transmit torque, but also effectively compensate for various deviations between shaft systems, ensuring the smooth operation of the transmission system. From heavy metallurgical equipment to high-speed trains, from mining machinery to precision machine tools, gear couplings are ubiquitous.

Geared coupling is a mechanical transmission device that achieves power transmission through gear meshing, belonging to the category of rigid movable couplings. The core design concept is to use meshing gear pairs to connect two shafts, while allowing for a certain degree of axial, radial, and angular deviation. This type of coupling mainly consists of four basic components: outer gear shaft sleeve, inner gear ring, sleeve assembly, and sealing and lubrication system. The outer gear shaft sleeve is usually installed at the end of the drive shaft, and its outer teeth mesh with the inner teeth of the inner gear ring to form a power transmission path. The sleeve serves as a connection and protection, enclosing the entire meshing system to prevent external contaminants from entering and maintain lubrication.

The working principle of geared couplings is based on the mechanical principle of precision gear meshing. When the driving shaft rotates, the internal gear ring that meshes with it is driven to rotate by the external gear shaft sleeve, thereby transmitting power to the driven shaft. During this process, the special design of the gears allows for a certain relative displacement between the two shafts. Specifically, geared couplings can compensate for parallel offsets of 0.01-0.02 inches (approximately 0.25-0.5 millimeters) and misalignment angles of up to 2 degrees, with some drum tooth designs even allowing for up to 6 degrees of deviation angle. This compensation capability eliminates the need for absolute perfect alignment during installation of geared couplings, greatly reducing installation difficulty and maintenance costs.

From the perspective of power transmission efficiency, geared couplings perform extremely well. Due to its direct meshing with metal gears, the energy loss during transmission is minimal, and the transmission efficiency can reach 99.7%, far higher than many other types of couplings. At the same time, the torque transmission capability of geared couplings is impressive, and the torque bearing range of standard products can reach the 4500kN · m level, which can meet the needs of the vast majority of heavy-duty industrial applications. The high efficiency and high torque characteristics make geared couplings the preferred choice for high-power transmission systems.

The material selection of geared couplings has a direct impact on their performance. The teeth of most geared couplings are made of high-quality alloy steel and undergo heat treatment processes such as quenching and carburizing to improve surface hardness and wear resistance. The sleeve part may be made of metal or high-strength engineering plastics (such as nylon) depending on the application scenario. Metal sleeves provide higher strength and durability, while nylon sleeves can reduce weight, lower noise, and have certain self-lubricating properties. The application of these material sciences ensures the reliable operation of geared couplings under various harsh working conditions.

Geared couplings can be classified into various types based on their tooth profile design and structural configuration, each with its unique performance characteristics and applicable scenarios. Understanding these classifications and their differences is crucial for selecting and using geared couplings correctly. In practical applications, engineers need to choose the most suitable type of geared coupling based on factors such as load characteristics, speed requirements, alignment accuracy, and installation space.

The spur geared coupling is the most basic form, with a straight tooth profile on its outer gear sleeve, simple structure, and low manufacturing cost. This type of coupling compensates for the relative displacement between the two shafts by increasing the backlash between the inner and outer teeth, but the compensation capability is limited and can generally only adapt to very small axis deviations. Straight tooth couplings are prone to edge contact during meshing, leading to stress concentration and potential uneven wear during long-term use. With the development of technology, spur geared couplings have gradually been replaced by drum geared couplings with better performance. Currently, they are mainly used in general transmission applications with low compensation requirements and low speeds.

Drum shaped geared coupling is currently the most widely used type of geared coupling in industry, representing the advanced level of modern geared coupling technology. Unlike the straight tooth design, the outer gear shaft sleeve of the drum shaped geared coupling is machined into a circular arc shape, and the entire tooth surface has a drum shaped structure. This innovative design brings multiple advantages: firstly, the drum shaped teeth significantly improve the tooth surface contact conditions, even when there is axis deviation, it can maintain surface contact instead of line contact, making the contact stress distribution more uniform; Secondly, the drum shaped teeth allow for a larger angle misalignment, with a compensation capability of up to 6 degrees, far exceeding the 2-degree limit of straight tooth couplings; Furthermore, this design eliminates the common edge compression phenomenon of spur geared couplings and reduces local stress concentration. Research has shown that under the same conditions, the torque transmission capacity of drum geared couplings is 15-30% higher than that of straight geared couplings, and their service life is significantly extended. Therefore, in heavy load fields such as metallurgy, mining, and lifting, drum geared couplings have become a standard configuration.

From the perspective of structural configuration, geared couplings can be divided into two standardized forms: CL type short couplings and CLZ type long couplings. The CL type is directly connected to two shafts by a pair of inner and outer gear sleeves, with a compact structure and suitable for situations with limited axial space; The CLZ type connects two half couplings through an intermediate shaft to form a longer transmission chain, which can adapt to the transmission needs of larger wheelbases. When the central axis is not long, the CLZ type can adopt a hollow design to reduce weight. Both types have achieved standardized production, with torque transmission capabilities covering various application scenarios below 100 tons per meter.

Geared couplings occupy an important position in the field of industrial transmission due to their excellent mechanical performance. The advantages of this type of coupling are reflected in multiple aspects, making it the preferred transmission solution for many harsh working conditions. Understanding these performance advantages can help engineers make more rational choices in equipment design and maintenance, fully leveraging the technical characteristics of geared couplings.

High torque density is one of the most significant advantages of geared couplings. Compared to other types of couplings, geared couplings can transmit greater torque at the same size, making them particularly valuable in space limited heavy-duty applications. The torque transmission capacity of modern geared couplings can reach 4500 kN · m, which is sufficient to meet the power requirements of the vast majority of industrial equipment. This powerful torque transmission capability stems from the high efficiency of gear meshing principle and the application of high-quality alloy steel materials. By accurately calculating the contact stress and bending stress of the tooth surface, engineers can optimize gear parameters to achieve maximum torque capacity of the coupling at the smallest size.

The precision transmission characteristics of geared couplings are also commendable. Due to the use of gear meshing principle, this coupling can ensure precise synchronization between the input shaft and the output shaft, with a constant transmission ratio and no slip phenomenon. Under high-speed operating conditions, geared couplings can still maintain excellent dynamic balance performance, with vibration and noise control at a low level. Some high-precision geared couplings that have undergone special dynamic balancing treatment can even be used in extreme high-speed situations such as gas turbines, with speeds reaching tens of thousands of revolutions per minute. This precise transmission characteristic makes geared couplings an ideal choice for transmission systems that require strict synchronization.

The ability to compensate for deviations constitutes another major technical advantage of geared couplings. Unlike rigid couplings that require strict alignment of shaft systems, geared couplings can effectively compensate for installation deviations in axial, radial, and angular directions. Especially in the design of drum shaped teeth, by making the outer teeth into spherical surfaces (with the center of the spherical surface on the gear axis) and increasing the tooth flank clearance, extraordinary deviation adaptability is achieved. In practical applications, geared couplings can compensate for parallel offsets of 0.01-0.02 inches and up to 6 degrees of misalignment (depending on the specific type), greatly reducing installation difficulty and minimizing vibration and wear issues caused by poor alignment. This compensation capability is particularly important for large equipment such as rolling mills and ship propulsion systems, as their shaft systems often experience dynamic displacement due to thermal deformation, foundation settlement, and other reasons.

The reliability and durability of geared couplings are renowned in the industry. The high-quality geared coupling is made of high-strength alloy steel, and the tooth surface has undergone hardening treatment such as carburizing and quenching. The surface hardness can reach HRC58-62, while the core maintains sufficient toughness to withstand impact loads. A reasonable lubrication system design further extends the service life, and under normal maintenance conditions, the geared coupling can operate stably for tens of thousands of hours. It is worth mentioning that the failure of geared couplings is usually gradual. By regularly checking the condition of the tooth surface and lubrication status, potential problems can be detected in advance and planned maintenance can be arranged to avoid production interruptions caused by sudden failures.

Based on these performance advantages, geared couplings have been widely used in many industrial fields. In the metallurgical industry, geared couplings are the core transmission components of key equipment such as hot strip mills and cold rolling mills, responsible for transmitting the power of electric motors to the rolling mills. The harsh conditions such as high temperature, heavy load, and impact load in the steel production process precisely highlight the high torque and durability advantages of geared couplings. Mining and lifting equipment are another major application area of geared couplings. Equipment such as ball mills, crushers, and bridge cranes rely on geared couplings to transmit huge torque and compensate for installation deviations. In these situations, couplings often need to withstand frequent starting, braking, and even reverse operations, and the sturdy characteristics of geared couplings ensure the reliable operation of the equipment.

In the field of energy, geared couplings are widely used in wind turbines, hydro turbines, and gas turbines. Especially in modern wind power applications, geared couplings connect the generator and gearbox, not only transmitting torque, but also absorbing vibration and compensating for shaft displacement caused by tower shaking. The field of rail transit also relies on geared couplings. In the gear transmission system of high-speed trains, precision geared couplings ensure efficient transmission of power from the traction motor to the wheelset, with a running speed of up to 160 to 350 kilometers per hour. In addition, geared couplings play an irreplaceable role in industries such as ship propulsion, petrochemicals, and heavy machinery,