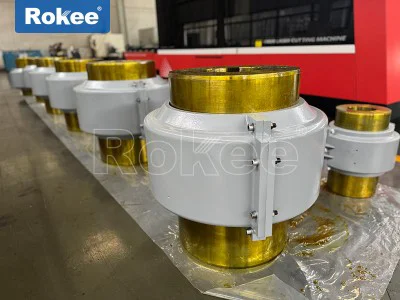

Steelflex Grid Couplings

Steelflex grid coupling is a mechanical transmission device that uses

special spiral springs as elastic elements. It connects shafts through

the elastic deformation of metal springs and compensates for the

relative displacement between the two shafts. This type of coupling

occupies an important position in the modern industrial transmission

field due to its unique structural design and excellent performance

characteristics.

Core working principle: The steelflex grid coupling is mainly composed of two half couplings and a serpentine spring placed in them. When power is input from one end, torque is transmitted to the other end through the elasticity of the serpentine spring. Springs produce controllable elastic deformation during the transmission of torque, which can not only absorb vibration and impact, but also automatically compensate for axial, radial, and angular deviations.

Structural characteristics of steelflex grid coupling

Serpentine Spring Component: A high elasticity spiral spring made of high-quality alloy steel, which has undergone special heat treatment and has extremely high fatigue life. Spring cross-sections are typically designed as rectangles or trapezoids to optimize stress distribution.

Coupling housing: a precision machined metal shell with tooth grooves on the inner wall that match the shape of the spring, ensuring that the spring can evenly distribute the load when subjected to force. Modern advanced models often use aviation aluminum alloy materials to reduce weight.

Lubrication system: Most steelflex grid couplings are equipped with long-lasting grease or oil grooves, and some high-performance products use self-lubricating composite materials, significantly reducing maintenance requirements.

Protective device: dustproof sealing ring and protective cover design to prevent external pollutants from entering the work area and extend the service life.

The outstanding advantages of the steelflex grid coupling

Excellent vibration damping performance: The elastic deformation of the spring can absorb up to 85% of the vibration energy, significantly reducing the amplitude of vibration transmitted to the driven shaft.

Super strong deviation compensation capability: The unique three-dimensional elastic structure can simultaneously compensate for axial, radial, and angular deviations.

Extremely low maintenance cost: The design life of high-quality products usually exceeds 50000 working hours, and models with long-term lubrication systems can achieve maintenance free operation for more than 5 years.

Overload protection function: When the torque exceeds the rated value, the spring will undergo greater deformation without immediately breaking, providing buffering time for the system.

Compact and efficient design: Compared to gear couplings with the same torque capacity, the serpentine spring type can reduce volume by 25-40% and weight by more than 30%, making it particularly suitable for applications with limited space.

Typical application areas and selection suggestions

In the field of heavy industry:

Large compressor units (such as natural gas pipeline compressors)

Rolling mill transmission system

Mining crushing equipment

Suggest choosing the heavy-duty series, paying attention to torque margin and dust resistance performanceEnergy industry:

Generator set (gas turbine, steam turbine)

Connection of wind power growth box

Water pump unit

Recommend using high-precision balanced version, with strict matching of speed requiredShip and Ocean Engineering:

Main propulsion system

Deck mechanical transmission

Power positioning system

Corrosion resistant models must be selected, taking into account their adaptability to seawater environmentsSpecial industrial applications:

Key equipment of nuclear power plant

Aerospace Test Stand

high-precision machine tool

Customized design is required, with a focus on material purity and temperature stability

Key technical points for installation and debugging

Alignment calibration:

Use a laser centering device to ensure axial deviation<0.05mm

Control the angular deviation within 0.02 °

Reserve appropriate axial clearance (usually 0.5-1.5mm)Pre tightening force adjustment:

Set according to the torque displacement curve provided by the manufacturer

The typical preload is 3-5% of the free length

Use a torque wrench to tighten evenly in stagesOperation monitoring:

Check temperature changes every 8 hours during the initial operation phase

The vibration value should be ≤ 2.5mm/s (RMS)

Regularly check the lubrication status (every 2000 operating hours)

The steelflex grid coupling is evolving towards a more intelligent, efficient, and long-lasting direction, continuing to consolidate its preferred position in key transmission fields. Correctly selecting and using this type of coupling can significantly improve equipment reliability and reduce full lifecycle costs, making it an ideal choice for optimizing modern industrial transmission systems.