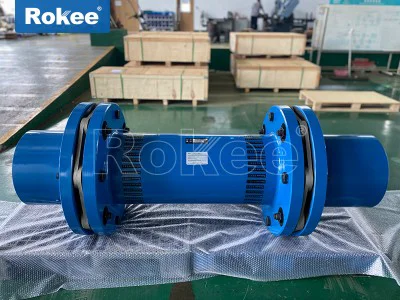

Metal Membrane Couplings

As a key component in modern mechanical transmission systems, metal membrane couplings occupy an important position in the industrial field with their excellent performance and wide applicability.

Metal membrane coupling is a high-performance flexible coupling with metal elastic elements, which compensates for the relative displacement between the two shafts connected by the elastic deformation of the metal diaphragm. This type of coupling is composed of several sets of stainless steel thin plates connected to the two halves of the coupling in a staggered manner with bolts. Each set of membranes is composed of several stacked pieces, which can be divided into connecting rod type and integral pieces of different shapes.

Compared with traditional couplings, metal membrane couplings have significant advantages such as compact structure, high strength, and long service life. It does not require lubrication, has no rotational clearance, and is not affected by temperature and oil stains. It also has the characteristics of acid resistance, alkali resistance, and corrosion resistance, making it particularly suitable for working environments with high temperature, high speed, and corrosive media. While transmitting torque and motion, it can effectively compensate for axial, radial, and angular offsets caused by manufacturing errors, installation errors, load deformation, and temperature rise changes.

The core structure of the metal membrane coupling is relatively simple but exquisitely designed:

Diaphragm group: composed of multiple layers of stainless steel thin plates stacked together, it is the elastic deformation element and core component of the coupling. According to design requirements, the diaphragm can be divided into two basic forms: linkage type and integral type. The quantity, shape, and thickness of the membrane directly affect the compensation capability and torque transmission performance of the coupling.

Shaft sleeve/flange: usually two, connecting the driving shaft and the driven shaft respectively. The shaft sleeve material is generally high-strength alloy steel or aluminum alloy, which is fixedly connected to the shaft end through keyway, clamping mechanism or expansion sleeve.

Connecting bolts: High strength bolts tightly connect the diaphragm group with the shaft sleeve, forming an integrated transmission structure. The pre tightening force and fitting accuracy of bolts have a decisive impact on the performance of couplings.

The metal membrane coupling achieves displacement compensation and torque transmission through the elastic deformation of the diaphragm:

Torque transmission: When the driving shaft rotates, the torque is transmitted to the diaphragm group through the flange, and then transmitted to the driven shaft through the other flange. The diaphragm mainly bears tensile and compressive stresses when transmitting torque.

Displacement compensation:

Axial displacement: The diaphragm absorbs axial deviation through its own elastic bending deformation

Radial displacement: The diaphragm undergoes conical deformation to adapt to radial displacement

Angular displacement: The membrane group presents an "S" - shaped bending to compensate for angular deviationVibration reduction characteristics: Metal diaphragms have certain damping properties, which can absorb and buffer vibrations and impacts in the transmission system, and reduce bearing loads.

It is worth noting that the compensation mechanism of single diaphragm and double membrane couplings is different. Single membrane couplings are not suitable for large eccentricities due to the complex bending of the diaphragm required; The double membrane coupling can bend in different directions at the same time, with stronger compensation capability, and can usually withstand deviations of up to 1.5 degrees.

Metal membrane couplings have a series of outstanding performance characteristics, making them the preferred choice in many application scenarios:

Excellent compensation capability: Compared with gear couplings, the angular displacement compensation capability can be doubled, the reaction force is small during radial displacement, and the flexibility is large. Typical parameters are axial displacement ± 0.5mm, radial displacement ± 0.2mm, and angular displacement ± 0.5 °.

Efficient transmission: With a transmission efficiency of up to 99.86% and minimal energy loss, it is particularly suitable for medium and high-speed high-power transmission systems.

Environmental adaptability: With a wide working temperature range (-80 ℃ to+300 ℃), it can operate stably in harsh environments such as oil, water, acid and alkali corrosive media, and can operate safely under impact and vibration conditions.

Maintenance free design: No need for lubrication and regular maintenance, saving operating costs. No wear parts, long service life.

Precision transmission: No backlash, can accurately transmit speed, operate without slip, and can be used for the transmission of precision machinery such as servo systems.

Safe and reliable: The structure is simple and compact, and the all metal structure has high strength. When overloaded, the diaphragm will break first, protecting other components of the equipment.

Metal membrane couplings can be classified into multiple types based on their structural form and application requirements, each with specific performance characteristics and applicable scenarios.

Classified by structure

Single membrane coupling:

The structure is the simplest, consisting of a set of membranes and two shaft sleeves

Suitable for situations where high precision is required and displacement compensation is not necessary

Typical models: JM type, DJM type, etcDouble membrane coupling:

Composed of two sets of membranes and an intermediate, it has stronger compensation capability

Can compensate for multiple composite displacements simultaneously, suitable for situations with poor centering accuracy

Typical models: JMI, JMII, SJM, etcMulti membrane coupling:

Having three or more sets of membranes for special high demand applications

Can withstand greater torque and more complex displacement

Classified by connection method

Keyway type: transmits torque through key connections, such as JM and JMI series

Clamping type: fixed by clamping sleeve, easy to install, such as TJM series

Expansion sleeve type: Connected through expansion sleeves, transmitting high torque without keys, such as the ZJM series

Flange type: connected by flange bolts, used for high-power transmission, such as MJF type