Flexible Gear Couplings

As a key component of modern mechanical transmission systems, flexible gear couplings are demonstrating unprecedented technological value in the field of intelligent manufacturing. The flexible gear coupling achieves flexible connection during the transmission process through a unique structural design, effectively solving the limitations of traditional rigid couplings in vibration absorption, deviation compensation, and noise control.

Flexible gear couplings are essential components in modern mechanical transmission systems, cleverly integrating the precision of gear transmission with the adaptability of flexible connections. Compared with traditional rigid couplings, flexible gear couplings can effectively compensate for various deviations between shaft systems while transmitting torque through specially designed meshing structures and elastic elements, providing a more reliable and efficient transmission solution for modern industrial equipment.

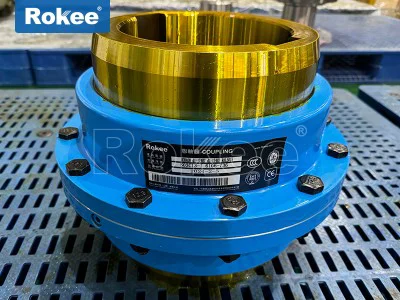

In terms of basic structure, flexible gear couplings typically consist of three main parts: an outer gear sleeve, an inner gear ring, and a sleeve component. External gear shaft sleeves are usually installed on the drive shaft, and their tooth tips are often designed in a spherical shape; The inner gear ring is installed on the driven shaft and forms a meshing relationship with the outer gear sleeve; The sleeve component can be designed in two types: flange sleeve and continuous sleeve, depending on the type. This structure enables the coupling to compensate for shaft system deviations through relative motion between gears while transmitting torque. In terms of material selection, modern flexible gear couplings often use high-strength alloy steel, stainless steel, or special nylon materials to meet the requirements of strength, wear resistance, and corrosion resistance under different working conditions.

The core advantages of flexible gear couplings are mainly reflected in three aspects: deviation compensation capability, vibration damping characteristics, and high transmission efficiency. In terms of deviation compensation, high-quality flexible gear couplings can simultaneously compensate for three types of deviations: axial, radial, and angular. Among them, the angular compensation ability can reach up to ± 3 °, the radial compensation amount can reach 0.2-6.3mm, and the axial compensation amount can reach ± 0.1mm. This multi-directional compensation ability greatly reduces the requirements for equipment installation accuracy and reduces additional loads caused by poor alignment. In terms of vibration control, the elastic elements in the coupling, such as polyurethane, rubber, or metal diaphragms, can effectively absorb and attenuate vibrations and impacts transmitted from the motor or load end, protecting the precision components in the transmission system. In terms of transmission efficiency, the optimized gear coupling can achieve a transmission efficiency of 99.7%, with almost no additional energy loss.

From the perspective of performance parameters, the torque bearing range of modern flexible gear couplings is extremely wide, from small encoder couplings of 0.05Nm to heavy-duty industrial couplings of 4500kN · m, which can meet the needs of the vast majority of industrial applications. In terms of rotational speed, ordinary rubber elastic couplings are suitable for medium and low-speed applications (usually below 5000rpm), while metal diaphragm couplings can be applied to ultra high speed conditions of 40000rpm. Temperature adaptability is also an important indicator. High quality couplings can work stably in the ambient temperature range of -50 ° C to 120 ° C, and specially designed couplings can even adapt to more extreme temperature environments.

In principle, flexible gear couplings transmit torque through gear meshing, while utilizing the deformation of elastic elements or the relative displacement of gear pairs to absorb vibration and compensate for deviations. Taking the drum shaped gear coupling as an example, when the spherical teeth of the outer gear sleeve mesh with the straight teeth of the inner gear ring, it allows for a certain angular and radial displacement between the two shafts without generating excessive additional stress. When the shaft system is misaligned, the gear pair automatically adjusts its position through relative sliding to maintain smooth power transmission. Elastic components (such as diaphragms, rubber blocks, etc.) absorb impact and vibration energy through their own elastic deformation while transmitting torque, protecting the transmission system from damage.

Flexible gear couplings can be classified into various types based on their structural design and material applications, each with its unique performance characteristics and applicable scenarios. Understanding these types and their differences is crucial for proper selection and optimization of transmission system performance.

The drum gear coupling represents a high-performance solution for traditional flexible gear couplings and is widely used in the field of heavy industry. The typical representative of this type of coupling is the GIICL type product, whose core feature is that the tooth tip of the outer gear shaft sleeve is spherical, which can achieve significant angular and radial deviation compensation when meshing with the inner gear ring. In terms of torque carrying capacity, the drum shaped gear coupling performs well, with a torque range of 20-40000 Nm, making it particularly suitable for heavy-duty applications such as steel mills, mining equipment, and large pump sets. In terms of deviation compensation capability, the allowable angular deviation is 1.5 °, and the radial deviation is 0.2-6.3mm, which can effectively absorb the foundation settlement and thermal deformation during equipment operation. In terms of material selection, the teeth are usually made of 20CrMnTi alloy steel that has undergone carburizing and quenching treatment, with a hardness of HRC58-62 and extremely high wear resistance and fatigue strength. The lubrication method is mostly grease lubrication, and lithium based grease needs to be added regularly to extend its service life. The GIICL drum gear coupling produced by Shanghai Dasheng Machinery Co., Ltd. adopts a special heat treatment process, which increases the product life by 30% compared to conventional products and has been widely used in the metallurgical industry.

Diaphragm couplings are outstanding in the field of precision transmission, particularly suitable for high-precision servo systems and robot applications. This type of coupling is composed of multiple layers of metal diaphragms (usually stainless steel) connected to the two end shaft sleeves through bolts, and its completely backless design makes it an ideal choice for position control systems.

Elastic element gear couplings use elastic materials such as rubber or polyurethane as buffering media, which have the advantages of simple structure and low cost. This type of coupling commonly has designs such as plum blossom, claw, and 8-shaped, which have excellent vibration reduction performance and electrical insulation characteristics, and are suitable for servo systems that are susceptible to electrical interference. The torque range is usually between 0.05-800Nm, suitable for small and medium power transmission. The choice of elastomer material directly affects the performance of the coupling. Ordinary nitrile rubber is suitable for general working conditions, while polyurethane material has higher strength and wear resistance. EPDM rubber is particularly suitable for high temperatures and outdoor environments. The disadvantage of this type of coupling is that the elastic components will age and require regular inspection and replacement. The general service life is 3-5 years.

Choosing a suitable flexible gear coupling is an engineering and technical decision that requires comprehensive consideration of multiple factors. The correct selection not only ensures the efficient and stable operation of the transmission system, but also extends the service life of the equipment and reduces maintenance costs. In the field of intelligent manufacturing, with the development of precision and high-speed equipment, the selection of couplings has become more critical, requiring comprehensive evaluation from multiple dimensions such as mechanical characteristics, dynamic performance, environmental adaptability, and economy.