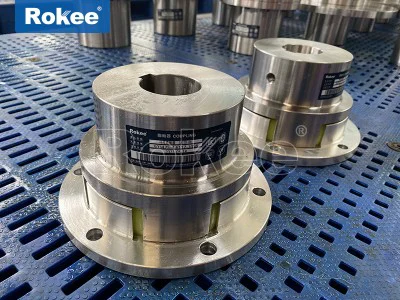

XL Star Flexible Coupling

XL star flexible coupling is a high-performance elastic coupling that occupies an important position in modern mechanical transmission systems due to its unique star shaped elastic body and flexible connection characteristics. This type of coupling effectively absorbs and compensates for various deviations of the shaft system through its elastic elements, providing smooth and reliable power transmission for mechanical equipment.

Compared with traditional rigid couplings, XL star flexible couplings have better vibration reduction performance, which can significantly reduce the vibration and noise of the transmission system and extend the service life of the equipment. Its compact structure and easy installation make it widely used in various industrial fields.

The XL star flexible coupling is mainly composed of the following key components:

Two half couplings: usually made of high-strength cast iron or steel, installed on the drive shaft and driven shaft respectively

Star shaped elastomer: The core component is made of specially formulated polyurethane or rubber material, which has excellent elasticity and wear resistance

Connecting components: including bolts, nuts, and other fasteners to ensure reliable connection of each component

Star shaped elastomers are the core innovation of XL couplings, characterized by:

Multi claw star design provides uniformly distributed elastic support

Special material formula ensures high torque transmission capability while maintaining good elasticity

Optimized geometric shape achieves multi-directional compensation capability

When power is transmitted from the drive shaft to the driven shaft, the star shaped elastic body undergoes controllable elastic deformation:

Absorb and compensate for axial, radial, and angular deviations

Buffer impact load through elastic deformation

Damping vibration energy to reduce resonance risk

Technical advantages and performance characteristics

Deviation compensation capability

XL star flexible coupling has excellent deviation compensation performance:

Radial deviation compensation: up to 0.5-3mm (depending on specifications)

Angular deviation compensation: usually 1 ° -3 °

Axial deviation compensation: allowing a certain range of axial displacementVibration and noise reduction characteristics

Compared to other types of couplings, XL star flexible couplings perform outstandingly in terms of vibration reduction:

Can reduce vibration amplitude by 30-50%

Significantly reduce transmission system noise

Effectively isolate the vibration transmission between the motor and the loadMaintenance and lifespan

No lubrication required, reducing maintenance workload

Easy and fast replacement of elastomers

Typical service life can reach 20000-50000 hours (depending on operating conditions)

Application field

Industrial automation equipment

Widely used in various automated production lines:

Mechanical arm transmission system

CNC machine feed mechanism

Power transmission of packaging machineryPump and fan system

Especially suitable for fluid equipment that requires vibration reduction:

Centrifugal pump drive connection

Industrial fan power transmission

Compressor shaft connectionOther industrial applications

Power generation equipment auxiliary system

Ship power transmission

Construction machinery transmission components

Selection and Installation Guide

Key selection parameters

When choosing XL star flexible couplings, the following factors should be considered:

Transmission torque requirements

Axis diameter size matching

Operating speed range

Environmental conditions (temperature, humidity, corrosiveness, etc.)Installation precautions

Proper installation is crucial for optimal performance:

Ensure that the two axes are aligned within the allowable deviation range

Tighten the connecting bolts according to the recommended torque value

Avoid forced installation that may cause pre deformation of the elastic body

Perform manual rotation inspection after installationMaintenance Recommendations

Regularly check the wear of the elastomer

Monitor the operating temperature of the coupling

Pay attention to abnormal vibrations or noise changes

Replace the elastomer according to the manufacturer's recommendation

The XL star flexible coupling with its excellent performance characteristics and wide application adaptability, will continue to play an important role in the industrial transmission field, providing efficient and reliable power connection solutions for various mechanical equipment.