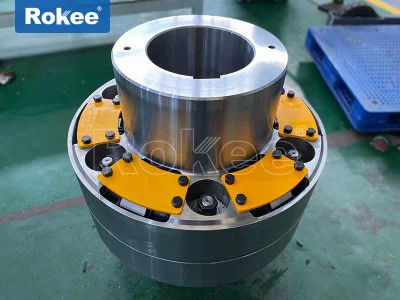

Expansion Sleeve Couplings

Expansion sleeve coupling is a keyless connection device widely used in modern mechanical transmission systems, which achieves high-precision connection between the shaft and the hub through the principle of mechanical expansion. This type of coupling consists of an inner sleeve. When axial force is applied, the inner sleeve expands, generating a huge radial pressure between the shaft and the hub, thereby achieving a seamless and secure connection.

The working principle is based on the principle of elasticity: when the bolt is tightened, the conical part of the expansion sleeve expands radially, causing both the inner and outer contact surfaces to be compressed simultaneously. This design not only eliminates the stress concentration problem caused by traditional key connections, but also achieves higher concentricity, and the transmission torque can reach 2-3 times that of traditional key connections.

The main types of expansion sleeve couplings

Single cone expansion sleeve: With a simple structure, it is suitable for medium load transmission, easy to install, and is the most common type in industry.

Double cone expansion sleeve: With two inner and outer conical surfaces, the clamping force distribution is more uniform, suitable for high torque and high-precision requirements.

Split type expansion sleeve: composed of multiple independent arc segments, especially suitable for connecting large equipment and large-diameter shafts.

Hydraulic expansion sleeve: It uses hydraulic principles to achieve expansion, making installation and disassembly more convenient, and is commonly used in situations that require frequent replacement.

Flange type expansion sleeve: Integrated flange design, can achieve axial positioning and torque transmission simultaneously, compact structure.

Compared with traditional keyway connections, the expansion sleeve coupling has significant advantages:

No gap connection: completely eliminating the fit gap, improving transmission accuracy, and significantly reducing vibration and noise.

Uniform stress distribution: avoids stress concentration caused by keyway and extends the service life of shaft and hub.

High torque transmission capability: With a large contact area, it can transmit even greater torque, up to three times that of traditional key connections.

Easy installation: No need for precision machining of keyways, greatly simplifying assembly processes and reducing manufacturing costs.

Easy maintenance: Reusable, easy to disassemble and reinstall, reducing downtime.

Multifunctionality: Simultaneously achieve axial, radial, and angular positioning, integrating multiple functions into one.

Key application areas of expansion sleeve couplings

Wind power industry: used for connecting generators and gearboxes to withstand huge alternating loads.

Machine tool manufacturing: High precision spindle connection ensures machining accuracy.

Mining machinery: transmission systems for heavy equipment such as crushers and ball mills.

Rail transit: Reliable connection between traction motor and gearbox.

Petrochemical industry: power transmission for large compressors and pumps.

Steel metallurgy: transmission of heavy equipment such as rolling mills and straightening machines.

Shipbuilding industry: propulsion system shaft connections.

Selection considerations:

Transmission torque requirements

Materials and dimensions of shafts and hubs

Working environment temperature

speed range

Do you need axial positioning function

Dynamic load characteristics

Installation steps:

Clean all contact surfaces, remove oil stains and burrs

Check if the matching dimensions meet the requirements

Apply an appropriate amount of lubricant (usually molybdenum disulfide)

Install in the center to ensure correct initial position

Tighten the bolts gradually in diagonal order

Use a torque wrench to achieve the specified torque value

Common mistakes to avoid:

Excessive tightening causes deformation of the expansion sleeve

Improper lubrication causes changes in friction coefficient

Incorrect installation causes additional load

Ignore the influence of temperature changes on preload force

Maintenance and upkeep of the expansion sleeve coupling

Regular inspection: Check the bolt pre tightening force every 6 months and re tighten if necessary.

Lubrication management: When reinstalling after disassembly, it is recommended to replace the lubricant with high-temperature grease.

Surface protection: When used in corrosive environments, surface protection treatment should be done well.

Temperature monitoring: Abnormal temperature rise may indicate overload or poor lubrication.

Vibration analysis: Regularly conduct vibration testing to detect potential problems early on.

Life assessment: Based on usage time and operating conditions, the replacement cycle is evaluated, and the general design life is 5-10 years.

As an important component of modern mechanical transmission systems, the expansion sleeve coupling is gradually replacing traditional connection methods and becoming the mainstream choice in the industrial field due to its excellent performance and reliability. With the advancement of manufacturing technology and the increasing demand for applications, this technology will continue to develop, providing more efficient and reliable connection solutions for mechanical equipment.