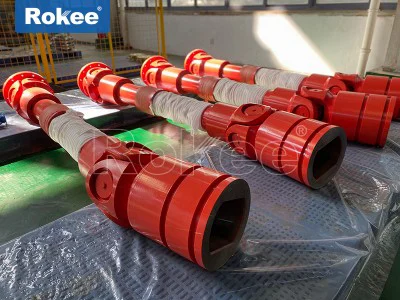

Cross Joint Shafts

The cross joint shaft is the core component of the universal joint transmission system, consisting of two mutually perpendicular shaft necks forming a cross shaped structure. Its core function is to achieve power transmission of angle changes between two axes, especially in scenarios that require flexible connections (such as automotive transmission systems), which can compensate for axial deviation, reduce vibration and wear.

Typical applications include

Automotive drive system: connects the gearbox and drive axle to adapt to bumps and steering during vehicle operation.

Industrial machinery: used in scenarios such as machine tools and engineering equipment that require non-linear transmission.

Technical characteristics and manufacturing processes

Material selection: High strength alloy steel (such as 20CrMnTi) is the mainstream material, which needs to undergo carburizing and quenching treatment to improve surface hardness and wear resistance while maintaining core toughness.

Precision machining: The cylindricity error of the shaft neck needs to be controlled at the micrometer level, and the installation accuracy of the needle roller bearing directly affects the service life. Some high-end products use grinding technology instead of turning to further reduce friction losses.

Lubrication design: Modern cross joint shafts often use sealed lubrication structures with built-in high-temperature grease, and some models are equipped with maintenance free designs to extend replacement cycles.