Jaw Couplings

Jaw Coupling is a common flexible coupling, named after its structural characteristics. This type of coupling transmits torque through the mutual engagement of two metal or elastic "claws" and is widely used in various mechanical transmission systems. Compared with traditional rigid couplings, Jaw Couplings have better buffering and vibration reduction performance, and can compensate for a certain degree of axial, radial, and angular deviations.

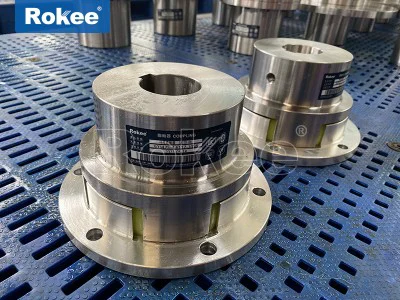

A typical Jaw Coupling consists of three core components:

Two metal wheels: usually made of aluminum alloy, steel, or stainless steel, installed on the drive shaft and driven shaft respectively

An elastic star shaped component: made of polyurethane, Hytrel or other elastic materials, located between two wheel hubs

Tightening bolt: used to fix the wheel hub on the shaft

The "claws" of Jaw Couplings usually exhibit the following characteristics:

Interlocking protrusions (usually 6-12)

Accurately designed meshing angle (usually 30-60 degrees)

Optimized tooth profile to reduce stress concentration

Surface treatment to improve wear resistance

Different components use different materials to meet performance requirements:

Wheel hub materials: aluminum alloy (light load), steel (heavy load), stainless steel (corrosive environment)

Elastic materials: polyurethane (universal), Hytrel (high temperature), natural rubber (high elasticity)

Special coating: galvanized, nickel plated or PTFE coating for special environments

The working principle of Jaw Coupling is based on the combination of elastic deformation and friction force:

The driving wheel hub compresses the elastic star shaped component through its claw shaped structure

Elastic deformation transfers force to the claws of the driven hub

Friction and elastic restoring force work together to achieve torque transmission

Advantages:

Good vibration reduction and absorption capability

Compensate for angular deviation of 0.5-3 ° and radial deviation of 0.1-0.5mm

No lubrication requirement, simple maintenance

Overload protection function (elastic body can slip)

Easy to install, no need for special tools

Limitations:

Relatively limited torque transmission

Heat accumulation may occur during high-speed operation

Elasticity has aging issues

Not suitable for situations that require precise phase maintenance

Correct installation steps

Clean the contact surface between the shaft and coupling

Check the fit tolerance between the shaft and coupling (usually H7/js6)

Use specialized tools for installation to avoid hammering

Tighten the fastening bolts evenly (in diagonal order)

Check the alignment situation (it is recommended to use a laser alignment device)

Common installation errors

Excessive tightening causes deformation of the elastic body

No, it's beyond the allowed range

Using inappropriate lubricants

Ignore the influence of environmental temperature

Maintenance Recommendations

Regularly check the condition of the elastomer (every 6 months)

Monitor operating temperature (should not exceed the temperature resistance limit of the elastomer)

Check the torque of the fastening bolts (every 12 months)

Record vibration data to predict replacement cycles

Industrial application field

General Machinery Manufacturing

Pump equipment: centrifugal pumps, gear pumps, etc

Fan system: industrial fans, ventilation equipment

Conveyor machinery: conveyor belt, elevatorAutomated equipment

Servo motor connection

Robot Joint Transmission

CNC machine tool auxiliary transmissionSpecial industrial fields

Food processing machinery (compliant with hygiene standards)

Pharmaceutical equipment (no pollution requirement)

Ship auxiliary system (corrosion-resistant design)

Jaw Couplings as an important component in the field of mechanical transmission, continue to play a crucial role in industrial applications due to their simple structure and reliable performance. With the advancement of materials science and manufacturing technology, Jaw Couplings will demonstrate their value in more emerging fields in the future.