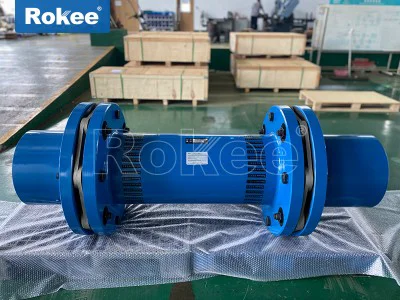

Metal Diaphragm Couplings

The metal diaphragm coupling is a flexible coupling with multiple layers of stainless steel thin plates (diaphragm groups) as the core component, which achieves power transmission by connecting the two halves of the coupling in a staggered manner with bolts.

The core feature of metal diaphragm couplings is the use of the elastic deformation of the diaphragm to compensate for axial, radial, and angular displacements, making them suitable for high-precision transmission scenarios. According to the number of membrane groups, they can be divided into:

Single diaphragm coupling: simple structure, suitable for mild eccentric working conditions.

Double diaphragm coupling: With the collaborative deformation of two sets of diaphragms, it has stronger compensation ability and can handle complex deviations (such as angular deviation up to 1.5 degrees).

Performance advantage

High precision and high efficiency

The transmission efficiency is as high as 99.86%, with no rotational clearance, ensuring precise speed transmission, suitable for servo systems, precision machine tools and other scenarios.

The static torsional stiffness can reach 3400N · m/rad (such as double diaphragm type), and the dynamic response is excellent.Environmental adaptability

Wide temperature resistance range (-80 ℃ to+300 ℃), stable operation in corrosive media (acid, alkali, oil).

No lubrication required, maintenance free design reduces long-term usage costs.Mechanical properties

The compensation capability is significantly better than that of gear couplings, with smaller radial displacement reaction force and a 100% increase in angular compensation capability.

The peak torque can reach twice the rated value and has overload protection function.

Membrane stress analysis

Thin film stress: generated by torque transmission, calculated as single piece torque (T1=T/m) (total torque/number of membrane groups).

Centrifugal stress: Inertial force acts during high-speed rotation, and the upper limit of the rotational speed needs to be controlled (such as the JZM type with a maximum of 10700 RPM).

Installation deviation stress: Axial/angular errors lead to periodic bending deformation, which is the main factor affecting fatigue life.

Materials and processes

The membrane is mostly made of 304 or 316L stainless steel, which is laser cut or stamped into shape, and the stacking thickness is usually 0.2-0.5mm.

The pre tightening force of the bolt needs to be precisely controlled, and the clearance requirements are strict (such as a clearance of 0.2-0.3mm between the flange hole and the bolt).

Selection criteria

Select the model based on torque (25-100000 N · m), speed (up to 15300 RPM), and shaft diameter (10-290mm).

Prioritize the intermediate shaft type (such as JMIJ series) to enhance deviation compensation capability.

Installation specifications

The axial deviation should be controlled within 1/3 of the allowable value (radial ≤ 0.05mm, angular ≤ 0.5 °).

The installation of bolts should be tightened in stages according to diagonal order, and a torque wrench should be used to ensure even torque.

Maintenance suggestions

Regularly check for membrane cracks or loose bolts, and it is recommended to perform dynamic balance testing every 5000 hours.

Under extreme working conditions, molybdenum disulfide coating can be applied to the membrane to extend its lifespan.

Metal diaphragm couplings with their irreplaceable performance advantages, are gradually replacing traditional gear couplings and becoming the preferred solution for modern industrial transmission systems.