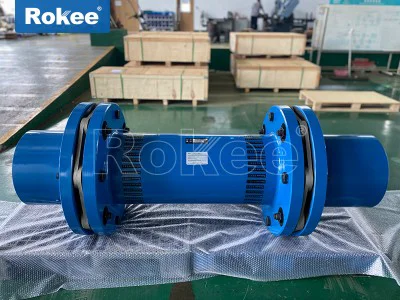

Laminated Membrane Couplings

Laminated membrane coupling is a high-performance metal elastic element flexible coupling, consisting of a multi-layer stainless steel thin plate laminated diaphragm group connected by high-strength bolts in a staggered manner between the two halves of the coupling.

The core principle of the laminated membrane coupling is to compensate for axial, radial, and angular deviations between two shafts through the elastic deformation of the diaphragm (with a compensation capacity of ± 1.5 ° angular displacement), while transmitting torque. Diaphragm design is divided into two types: linkage type and integral type. Among them, the double laminated membrane coupling can handle multi-directional offset simultaneously through the collaborative deformation of two sets of diaphragms, which is suitable for higher precision transmission scenarios.

Feature

Non lubrication design: The metal film does not require lubrication, avoiding oil pollution, and is suitable for industries with high cleaning requirements such as food and pharmaceuticals.

Environmental adaptability: With a wide temperature range (-80 ℃ to+300 ℃), it is resistant to acid and alkali corrosion and can operate stably in harsh conditions such as petroleum and chemical industries.

Efficient transmission: With a transmission efficiency of up to 99.86%, no rotational clearance, and precise speed transmission, it is suitable for precision equipment such as servo motors and high-speed pumps.

Vibration and noise reduction: The elastic deformation of the diaphragm can effectively absorb vibrations, reduce operating noise, and extend equipment life.

Classification and Selection Points

Single laminated membrane coupling: simple structure, suitable for light load, low offset scenarios, and low cost.

Double laminated membrane coupling (such as SJM type): With stronger compensation capability, it is suitable for high-power, long wheelbase transmission, such as wind power and metallurgical equipment.

Expansion sleeve coupling: achieves keyless connection through expansion sleeve, easy installation and does not damage the shaft body, commonly used in heavy machinery.

Key parameters for selection:

Torque range (10Nm to 8.1 million Nm)

Speed limit (some models can reach up to 60000 revolutions per minute)

Shaft hole form (cylindrical/conical)

Installation and maintenance specifications

Installation steps:

Clean the shaft end and apply lubricating grease, using the diagonal tightening bolt method (gradually increasing to the rated torque).

Ensure that the axial clearance is the thickness of the diaphragm plus 0.5mm to avoid deformation of the diaphragm due to excessive tightness.Common faults:

Abnormal noise: It is often caused by excessive axial offset or loose bolts, and needs to be recalibrated for centering.

Diaphragm fracture: caused by long-term overload or fatigue accumulation, requiring regular inspection and replacement.Maintenance suggestion:

Check the bolt preload and diaphragm status every 2000 hours of operation.

In extreme environments, molybdenum disulfide coating can be sprayed on the membrane to enhance wear resistance.

Application

Energy sector: high-speed shaft connections for gas turbines and wind turbines.

Transportation: Anti impact transmission of ship propulsion systems and high-speed rail drive devices.

Industrial manufacturing: Precision power transmission for CNC machine tool spindles and chemical pumps.

Laminated membrane couplings, with their reliability and adaptability, are gradually replacing traditional gear couplings and becoming the preferred solution for modern industrial transmission. Proper selection and standardized installation are the key to maximizing its performance.